Table of Contents

Benefits of Using a Water flow meter in Industrial Applications

Water flow meters are essential tools in industrial applications for measuring the flow rate of water in pipes and systems. These devices provide accurate and reliable data that can help businesses optimize their processes, improve efficiency, and reduce costs. In this article, we will explore the benefits of using a water flow meter in industrial applications.

One of the primary benefits of using a water flow meter is the ability to monitor and control water usage. By accurately measuring the flow rate of water in a system, businesses can identify areas of inefficiency and implement measures to reduce water consumption. This not only helps to conserve water resources but also leads to cost savings for the company.

Additionally, water flow meters can help businesses detect leaks and other issues in their water systems. By monitoring the flow rate of water over time, businesses can identify sudden drops in flow that may indicate a leak or other problem. This early detection can prevent costly damage to equipment and infrastructure, as well as minimize water wastage.

Another benefit of using a water flow meter is the ability to track water usage for billing and regulatory compliance purposes. Many industries are required to report their water usage to regulatory agencies, and accurate flow meter data can help businesses meet these requirements. Additionally, businesses can use flow meter data to accurately bill customers for water usage, ensuring fair and transparent billing practices.

| Model | pH/ORP-5500 pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP: (-2000~+2000)mV; Temp.:(0.0~99.9)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | Range: (0~120)°C; element: Pt1000 |

| Buffer Solution | pH value 9.18; 6.86; 4.01; 10.00; 7.00; 4.00 |

| Medium Temp. | (0~50)°C (with 25°C as standard) manual/automatic temp. compensation for selection |

| Analog output | Isolated (4~20)mA, Instrument/Transmitter for selection |

| Control Output | Double relay output (ON/OFF); AC 240V/3A |

| Working Environment | Temp.(0~50)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V; AC 110V; AC220V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx105mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

Water flow meters also play a crucial role in process optimization and quality control. By monitoring the flow rate of water in industrial processes, businesses can identify bottlenecks, inefficiencies, and other issues that may be affecting production. This data can help businesses make informed decisions to improve processes, increase productivity, and maintain product quality.

Furthermore, water flow meters can help businesses ensure the proper operation of equipment and machinery that rely on water flow. By monitoring flow rates, businesses can detect issues such as clogs, blockages, or pump failures that may affect the performance of equipment. This proactive approach to maintenance can help prevent costly downtime and repairs, as well as extend the lifespan of equipment.

In conclusion, the benefits of using a water flow meter in industrial applications are numerous. From monitoring and controlling water usage to detecting leaks and optimizing processes, water flow meters play a crucial role in helping businesses improve efficiency, reduce costs, and ensure regulatory compliance. By investing in a high-quality water flow meter, businesses can reap the rewards of accurate and reliable data that can help them make informed decisions and stay ahead of the competition.

How to Choose the Right Water flow meter for Your Specific Needs

Water flow meters are essential tools for measuring the flow rate of water in various applications, from residential to industrial settings. Choosing the right water flow meter for your specific needs is crucial to ensure accurate and reliable measurements. With a wide range of options available on the market, it can be overwhelming to select the most suitable one. In this article, we will discuss the factors to consider when choosing a water flow meter and provide guidance on selecting the best option for your requirements.

Another important factor to consider is the flow rate range that the water flow meter is capable of measuring. Flow meters are designed to measure a specific range of flow rates, and choosing one that is compatible with the flow rates in your system is essential for accurate measurements. It is important to select a flow meter that can handle the maximum flow rate expected in your system without compromising accuracy.

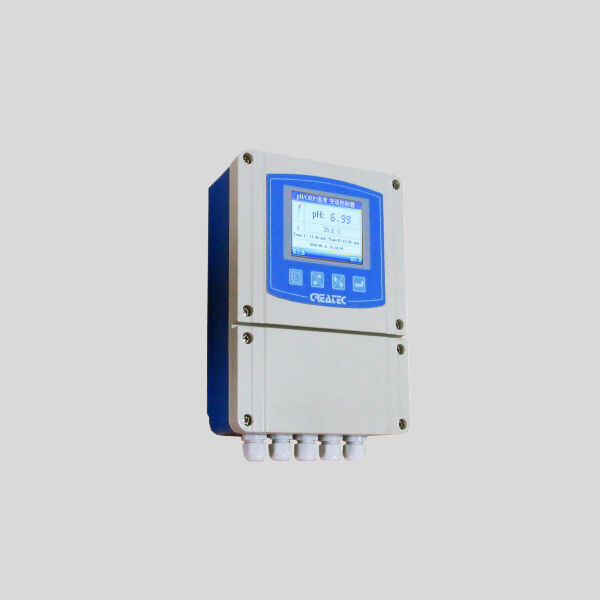

| Product name | PH/ORP-6900 pH/ORP transmitter controller | ||

| Measurement parameter | Measurement Range | Resolution ratio | Accuracy |

| pH | 0.00~14.00 | 0.01 | ±0.1 |

| ORP | (-1999~+1999)mV | 1mV | ±5mV(electric meter) |

| Temperature | (0.0~100.0)℃ | 0.1℃ | ±0.5℃ |

| Temperature range of Tested solution | (0.0~100.0)℃ | ||

| Temperature component | Pt1000 thermal element | ||

| (4~20)mA Current output | Channel No. | 2 Channels | |

| Technical characteristics | Isolated, fully adjustable, reverse, configurable, instrument / transmitting dual mode | ||

| Loop resistance | 400Ω(Max),DC 24V | ||

| Transmission accuracy | ±0.1mA | ||

| Control contact1 | Channel No | 2 Channels | |

| Electric contact | Semiconductor photoelectric switch | ||

| Programmable | Each channel can be programmed and point to (temperature, pH/ORP, time) | ||

| Technical characteristics | Presetting of normally open / normally closed state / pulse /PID regulation | ||

| Load capacity | 50mA(Max)AC/DC 30V | ||

| Control contact2 | Channel No. | 1 Channel | |

| Electric contact | Relay | ||

| Programmable | Each channel can be programmed and point to (temperature, pH/ORP) | ||

| Technical characteristics | Presetting of normally open / normally closed state / pulse /PID regulation | ||

| Load capacity | 3AAC277V / 3A DC30V | ||

| Data communication | RS485, MODBUS standard protocol | ||

| Working power supply | AC220V±10% | ||

| Overall power consumption | <9W | ||

| Working environment | Temperature: (0~50) ℃ Relative humidity: ≤ 85% (non condensing) | ||

| Storage environment | Temperature: (-20~60) C Relative humidity: ≤ 85% (non condensing) | ||

| Protection level | IP65 | ||

| Shape size | 220mm×165mm×60mm (H×W×D) | ||

| Fixed mode | Wall hanging type | ||

| EMC | Level 3 | ||

The accuracy of the water flow meter is also a critical factor to consider. The accuracy of a flow meter is typically expressed as a percentage of the actual flow rate, and choosing a flow meter with the appropriate level of accuracy for your application is essential. Higher accuracy flow meters may be more expensive, but they can provide more reliable measurements, especially in applications where precise flow rate measurements are required.

In addition to accuracy, the repeatability of the water flow meter is another important consideration. Repeatability refers to the ability of the flow meter to provide consistent measurements when the same flow conditions are repeated. A flow meter with good repeatability will produce consistent results over time, which is essential for monitoring and controlling water flow in a system.

The type of technology used in the water flow meter is also a key factor to consider. There are several types of flow meters available, including mechanical, electromagnetic, ultrasonic, and thermal flow meters. Each type of flow meter has its own advantages and limitations, so it is important to choose a technology that is suitable for your specific application.

When selecting a water flow meter, it is also important to consider the installation requirements. Some flow meters may require specific installation conditions, such as straight pipe lengths or mounting orientations, to ensure accurate measurements. It is important to ensure that the flow meter can be installed properly in your system to avoid any issues with measurement accuracy.

In conclusion, choosing the right water flow meter for your specific needs requires careful consideration of several factors, including the type of application, flow rate range, accuracy, repeatability, technology, and installation requirements. By taking these factors into account and selecting a flow meter that is suitable for your requirements, you can ensure accurate and reliable measurements of water flow in your system.