Table of Contents

Importance of Conductivity Meters in Water Quality Testing

Conductivity meters are essential tools used in water quality testing to measure the ability of a solution to conduct an electric current. This measurement is crucial in determining the purity and overall quality of water, as conductivity is directly related to the concentration of ions present in the solution. Conductivity meters are widely used in various industries, including environmental monitoring, wastewater treatment, and food and beverage production, to ensure that water meets regulatory standards and is safe for consumption.

One of the key advantages of conductivity meters is their ability to provide quick and accurate results. By simply immersing the probe of the meter into a water sample, users can obtain real-time measurements of conductivity, allowing for immediate assessment of water quality. This rapid feedback is especially important in situations where timely decisions need to be made, such as during water treatment processes or in emergency response situations.

| ROC-2315 ro controller instruction (220V) | |||

| Model | ROC-2315 | ||

| Single detection | Dry Contact input | Raw water no water protection | |

| (six channels) | Low-pressure protection | ||

| High-pressure protection | |||

| Pure water tank high level | |||

| External control mode signal | |||

| Running reset | |||

| Control port | Dry Contact output | Raw water pump | SPST-NO low capacity : AC220V/3A Max ;AC110V/5A Max |

| (five channels) | Inlet valve | ||

| High pressure pump | |||

| Flush valve | |||

| Conductivity over-limit drainge valve | |||

| Measurement detection point | Product water conductivity and with Automatic Temperature compensation (0~50)℃ | ||

| Measurement range | Conductivity : 0.1~200μS/cm/1~2000μS/cm/10~999μS/cm (with different conductivity sensor ) | ||

| Product water temp. : 0~50℃ | |||

| Accuracy | 1.5 level | ||

| Power supply | AC220V (±10%) , 50/60Hz | ||

| Working environment | Temperature:(0~50)℃ ; | ||

| Relative Humidity :≤85%RH (no condensation ) | |||

| Dimension | 96×96×130mm( height ×width×depth) | ||

| Hole size | 91×91mm(height ×width) | ||

| Installation | Panel mounted ,fast installtion | ||

| Certification | CE | ||

In addition to providing fast results, conductivity meters are also highly sensitive instruments that can detect even small changes in water quality. This level of sensitivity is crucial for detecting contaminants or impurities in water that may not be visible to the naked eye. By monitoring conductivity levels, users can identify potential issues early on and take corrective actions to prevent further contamination or deterioration of water quality.

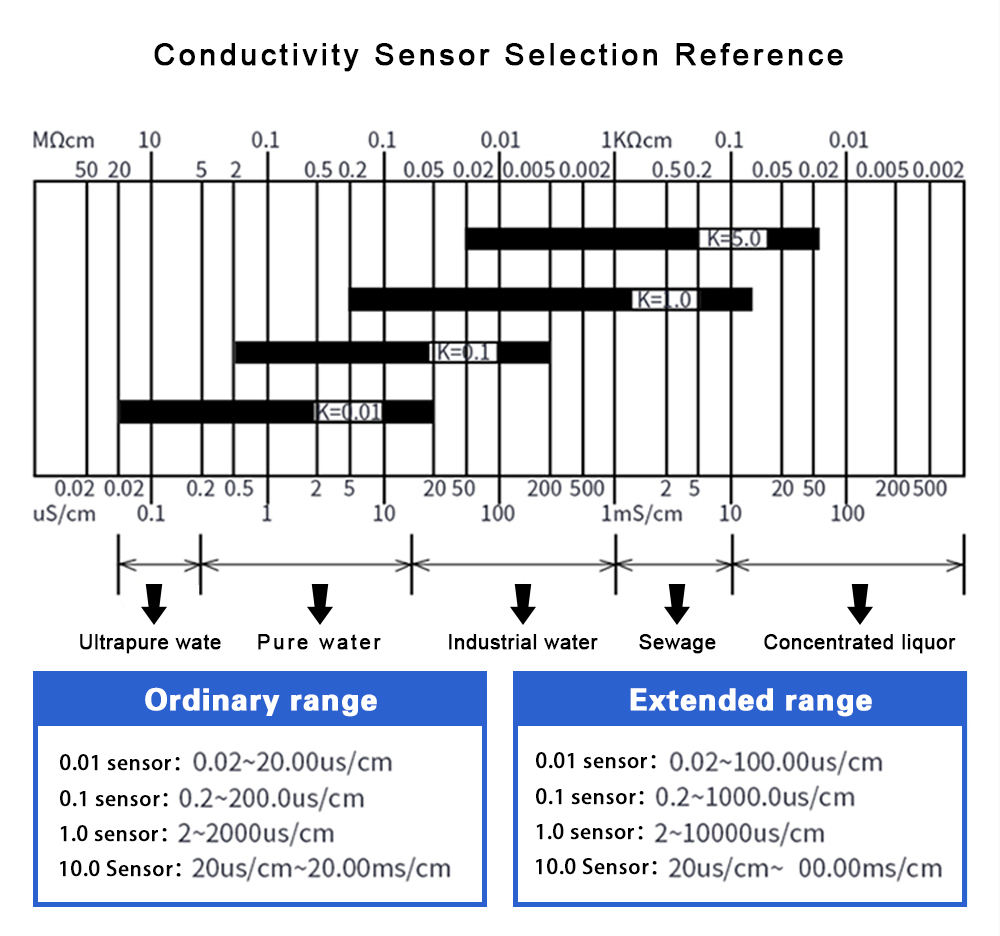

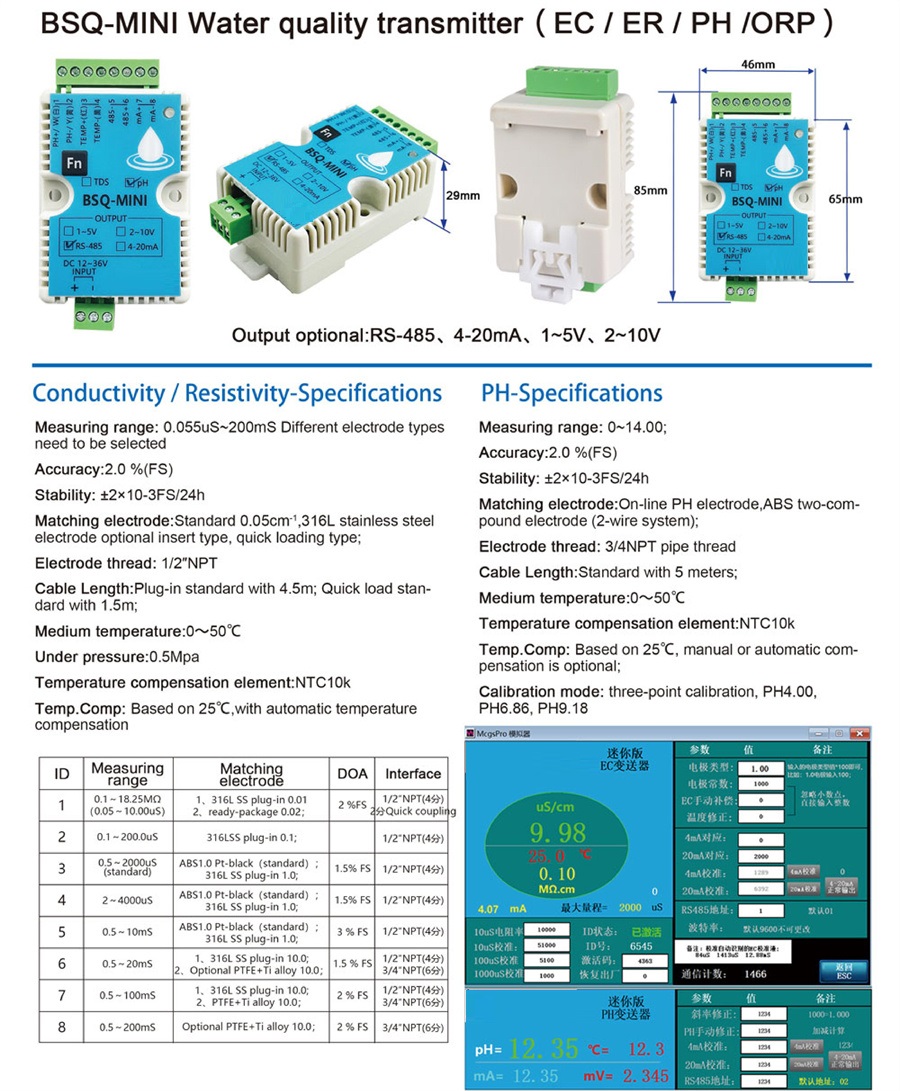

Furthermore, conductivity meters are versatile tools that can be used to measure a wide range of water samples, from pure distilled water to highly concentrated solutions. This flexibility makes conductivity meters suitable for a variety of applications, including testing drinking water, industrial wastewater, and agricultural runoff. By adjusting the settings on the meter, users can obtain accurate readings across different conductivity ranges, ensuring that the instrument is suitable for their specific testing needs.

Another important aspect of conductivity meters is their ease of use and portability. Most modern conductivity meters are compact and lightweight, making them ideal for fieldwork or on-site testing. With simple calibration procedures and user-friendly interfaces, conductivity meters are accessible to a wide range of users, from laboratory technicians to environmental scientists. This accessibility allows for widespread adoption of conductivity meters in water quality testing, contributing to the overall improvement of water management practices.

In conclusion, conductivity meters play a crucial role in water quality testing by providing fast, accurate, and sensitive measurements of conductivity levels in water samples. These instruments are essential for monitoring water quality in various industries and applications, ensuring that water meets regulatory standards and is safe for consumption. With their versatility, ease of use, and portability, conductivity meters have become indispensable tools for environmental monitoring and water management. As the demand for clean and safe water continues to grow, the importance of conductivity meters in ensuring water quality cannot be overstated.

How to Calibrate and Maintain a conductivity meter

A conductivity meter is a device used to measure the ability of a solution to conduct electricity. This measurement is important in various industries, including water treatment, pharmaceuticals, and food production. Conductivity meters are essential tools for ensuring the quality and consistency of products and processes. To maintain the accuracy of these devices, regular calibration and maintenance are necessary.

Calibration is the process of adjusting a conductivity meter to ensure accurate readings. This is typically done by comparing the meter’s readings to a known standard solution. The calibration process may vary depending on the type of conductivity meter being used, but it generally involves adjusting the meter’s settings to match the standard solution’s conductivity value.

Before calibrating a conductivity meter, it is important to gather all the necessary materials, including the standard solution, a clean beaker, and a calibration kit if required. It is also essential to follow the manufacturer’s instructions for calibration, as different meters may have specific calibration procedures.

To calibrate a conductivity meter, start by rinsing the electrode with distilled water to remove any residue. Then, place the electrode in the standard solution and allow it to stabilize for a few minutes. Once the reading stabilizes, adjust the meter’s settings to match the standard solution’s conductivity value. Repeat this process for multiple standard solutions to ensure the accuracy of the calibration.

| Model | pH/ORP-9500 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~50℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit triple relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×132mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

After calibrating the conductivity meter, it is important to regularly maintain the device to ensure accurate readings. This includes cleaning the electrode with a mild detergent and rinsing it with distilled water after each use. It is also important to store the conductivity meter properly in a clean, dry place to prevent contamination and damage.

In addition to regular cleaning and storage, it is recommended to perform routine maintenance checks on the conductivity meter. This may include checking the electrode for signs of wear or damage, as well as ensuring that the meter’s settings are still accurate. If any issues are detected during maintenance checks, it is important to address them promptly to prevent inaccurate readings.

In conclusion, a conductivity meter is a valuable tool for measuring the ability of a solution to conduct electricity. To maintain the accuracy of these devices, regular calibration and maintenance are essential. By following the manufacturer’s instructions for calibration, cleaning the electrode after each use, and performing routine maintenance checks, you can ensure that your conductivity meter provides accurate and reliable readings. Proper calibration and maintenance of a conductivity meter are crucial for ensuring the quality and consistency of products and processes in various industries.