Understanding the Functionality and Maintenance of Water Softener Nozzle and Venturi

The water softener nozzle and venturi are integral components of a water softening system, playing a crucial role in the process of water softening. Understanding their functionality and maintenance is essential for ensuring the longevity and efficiency of your water softening system.

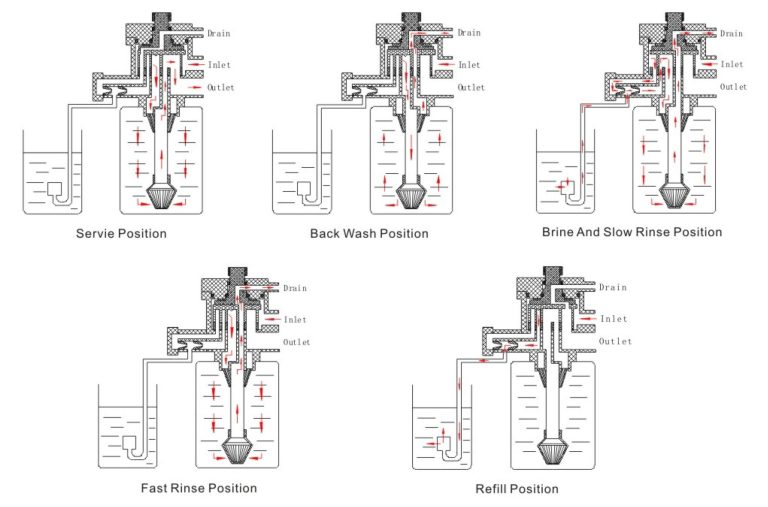

The water softener nozzle and venturi work in tandem to create a suction effect, which is pivotal in the regeneration process of the water softener. The venturi, a tube with a constricted throat, increases the velocity and decreases the pressure of water flowing through it. This decrease in pressure creates a suction effect, drawing brine from the brine tank into the resin tank. The brine, a solution of water and salt, then interacts with the resin beads in the resin tank, replacing the hardness ions with sodium ions, thereby softening the water.

The nozzle, on the other hand, is responsible for directing the flow of water. It ensures that the brine solution is evenly distributed across the resin tank, allowing for a thorough and efficient ion exchange process. The nozzle also aids in the backwash cycle, where water is forced through the resin tank at a high speed to flush out the hardness ions and regenerate the resin beads.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 3900 | 3.5″(3″) O.D. | 2″NPTF | 1″NPTM | 6″-8UN | 171W | 1℃-43℃ |

In addition to cleaning, it’s also important to regularly inspect the nozzle and venturi for any signs of damage. If any cracks, chips, or other signs of wear are noticed, the components should be replaced immediately. Using damaged components can lead to inefficiencies in the water softening process and may even cause further damage to the system.

While the maintenance of the water softener nozzle and venturi may seem like a daunting task, it is a relatively simple process that can be done by most homeowners. However, if you’re uncomfortable performing these tasks yourself, or if you notice any issues with your water softening system that you can’t resolve, it’s always best to consult with a professional.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| ASDU2 | automatic softener valve | 2 | O | O | O | O |

| ASDU2-H | automatic softener valve | 2 | O | O | X | X |

| ASDU4 | automatic softener valve | 4 | O | O | O | O |

| ASDU4-L | automatic softener valve | 4 | O | O | O | O |

In conclusion, the water softener nozzle and venturi are vital components that play a significant role in the water softening process. Understanding their functionality and the importance of regular maintenance can help ensure that your water softening system operates efficiently and effectively for many years. By taking the time to clean and inspect these components regularly, you can prevent potential issues and prolong the lifespan of your water softening system.