Table of Contents

Understanding the Functionality of Clack twin alternating softener

The Clack twin alternating softener is a revolutionary water softening system that has been designed to provide a continuous supply of softened water to households and businesses. This innovative system is characterized by its twin tank design, which allows one tank to be in service while the other is regenerating. This ensures that there is always a tank available to supply softened water, even during periods of high demand or when the system is regenerating.

The Clack twin alternating softener operates on the principle of ion exchange, a process that removes hard water minerals such as calcium and magnesium from the water. These minerals are responsible for the formation of scale in pipes and appliances, which can lead to reduced efficiency and increased maintenance costs. By removing these minerals, the Clack twin alternating softener helps to extend the lifespan of appliances and plumbing systems, while also improving the quality of the water.

The system consists of two resin tanks filled with ion exchange resin, a brine tank for regeneration, and a control valve that directs the flow of water. The control valve is programmed to switch from one tank to the other based on water usage, ensuring that there is always a tank in service. This is a significant advantage over single tank systems, which can run out of softened water during periods of high demand or regeneration.

The regeneration process is initiated when the resin in one of the tanks becomes saturated with hard water minerals. The control valve then directs water to the brine tank, where it mixes with salt to create a brine solution. This solution is then flushed through the saturated resin tank, where it exchanges the hard water minerals for sodium ions. Once the regeneration process is complete, the control valve switches back to the regenerated tank, and the process begins again with the other tank.

One of the key benefits of the Clack twin alternating softener is its efficiency. Because the system is always in service, it can operate at a lower capacity, which reduces the amount of salt and water used for regeneration. This not only saves on operating costs but also makes the system more environmentally friendly.

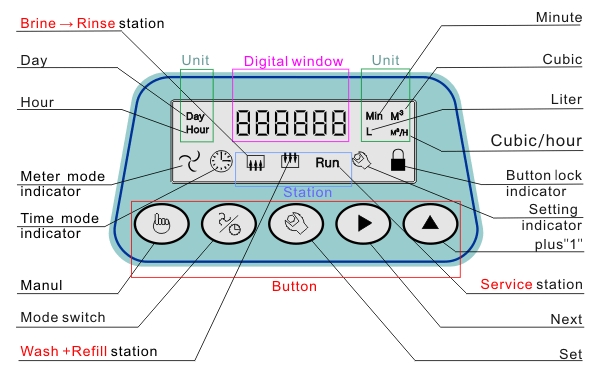

Furthermore, the Clack twin alternating softener is designed for ease of use. The control valve features a user-friendly interface that allows for easy programming and monitoring of the system. In addition, the system is equipped with a bypass valve that allows for the supply of hard water during maintenance or emergencies.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 9100 | 1.05″ O.D. | 1/2″NPT | 1600-3/8″ | 2-1/2″-8NPSM | 8.9W | 1℃-43℃ |

In conclusion, the Clack twin alternating softener is a highly efficient and reliable water softening solution. Its twin tank design ensures a continuous supply of softened water, while its ion exchange process effectively removes hard water minerals. With its user-friendly interface and environmentally friendly operation, the Clack twin alternating softener represents a significant advancement in water softening technology. Whether for a household or a business, this system offers a practical and cost-effective solution for hard water problems.

The Benefits and Installation Process of Clack twin alternating softener

The Clack twin alternating softener is a revolutionary product that has been making waves in the water treatment industry. This innovative system offers a myriad of benefits, from improved water quality to significant cost savings, making it an excellent investment for homeowners and businesses alike. Moreover, the installation process is straightforward, allowing for quick and easy setup.

One of the primary benefits of the Clack twin alternating softener is its ability to provide a continuous supply of softened water. Traditional water softeners regenerate, or recharge, at set intervals, which can lead to periods of hard water. However, the Clack system features two tanks that alternate in their operation. When one tank is regenerating, the other is supplying softened water, ensuring a constant flow of treated water. This is particularly beneficial for households or businesses with high water usage, as it eliminates the risk of running out of softened water.

In addition to providing a continuous supply of softened water, the Clack twin alternating softener is also highly efficient. It uses a metered regeneration process, which means it only regenerates when necessary based on your water usage. This not only conserves water but also reduces the amount of salt required for the regeneration process. Over time, these savings can add up, making the Clack system a cost-effective solution for water treatment.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| ASDU2 | automatic softener valve | 2 | O | O | O | O |

| ASDU2-H | automatic softener valve | 2 | O | O | X | X |

| ASDU4 | automatic softener valve | 4 | O | O | O | O |

| ASDU4-L | automatic softener valve | 4 | O | O | O | O |

The Clack twin alternating softener also contributes to the longevity of your appliances and plumbing system. Hard water can cause scale buildup in pipes and appliances, leading to decreased efficiency and potential damage. By softening your water, the Clack system helps to prevent this buildup, extending the lifespan of your appliances and reducing maintenance costs.

Despite these numerous benefits, some may be hesitant about the installation process. However, installing a Clack twin alternating softener is relatively straightforward. The system comes with a detailed instruction manual, and many homeowners find they can complete the installation themselves. However, if you’re not comfortable with DIY projects, professional installation is always an option.

The first step in the installation process is to choose a location for the softener. It should be installed near a drain and a power source, and there should be enough space for both tanks. Once the location has been chosen, the next step is to connect the softener to your water supply. This involves attaching the inlet and outlet pipes to the softener using the provided fittings.

After the softener is connected to the water supply, the next step is to connect it to the drain. This is done using a drain line, which is also included with the system. The final step is to plug the softener into a power source and program the control valve according to your water hardness and usage.

In conclusion, the Clack twin alternating softener offers numerous benefits, including a continuous supply of softened water, increased efficiency, and extended appliance lifespan. Moreover, the installation process is straightforward, making it an excellent choice for those seeking a reliable and cost-effective water treatment solution. Whether you’re a homeowner looking to improve your water quality or a business owner seeking to reduce operating costs, the Clack twin alternating softener is a worthy investment.