Table of Contents

Understanding the Intricacies of Zone control valve Operations

Understanding the intricacies of zone control valve operations requires a deep dive into the world of plumbing and heating systems. These valves, often overlooked, play a crucial role in maintaining the comfort and efficiency of our homes and offices.

A zone control valve, in its simplest form, is a device that regulates the flow of water or steam in a heating system. It is designed to control the distribution of heat in different zones or areas within a building. This means that each room or area can have its own temperature setting, providing a level of comfort and efficiency that is not possible with a single thermostat system.

The operation of a zone control valve is relatively straightforward. When the thermostat in a particular zone calls for heat, the valve opens, allowing hot water or steam to flow into the heating elements in that zone. Once the desired temperature is reached, the valve closes, stopping the flow and conserving energy.

However, the intricacies of zone control valve operations go beyond this basic function. For instance, some valves are equipped with a manual override feature. This allows the user to manually open or close the valve, bypassing the thermostat. This can be particularly useful in situations where the thermostat is malfunctioning or during maintenance work.

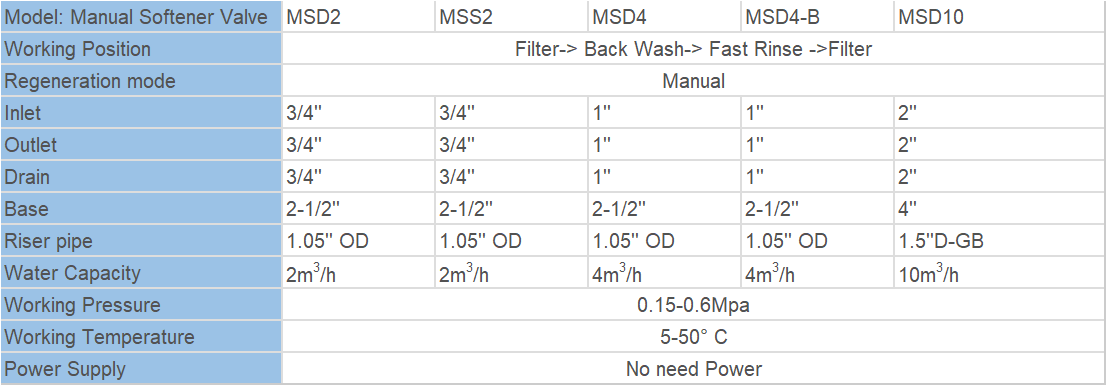

Moreover, zone control valves are not one-size-fits-all. They come in different sizes and types, each designed for a specific application. For example, a two-way zone valve is used in systems where the flow of water or steam is in one direction only. On the other hand, a three-way zone valve is used in systems where the flow can be directed in two different directions.

The choice of a zone control valve also depends on the type of heating system. For instance, in a hydronic heating system, which uses water as the heat-transfer medium, a motorized zone valve is typically used. This type of valve uses an electric motor to open and close the valve. In contrast, in a steam heating system, a thermostatic zone valve is often used. This type of valve uses a wax-filled element that expands and contracts with temperature changes to open and close the valve.

The installation and maintenance of zone control valves are also critical aspects of their operation. These valves should be installed by a professional to ensure proper functioning and to avoid potential damage to the heating system. Regular maintenance, including checking for leaks and ensuring that the valve is opening and closing properly, is also essential to prolong the life of the valve and maintain the efficiency of the heating system.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| ASE2 | Advanced Function automatic softener valve | 2 | O | X | X | X |

| ASE4 | Advanced Function automatic softener valve | 4 | O | X | X | X |

| ASS2 | automatic softener valve | 2 | O | O | O | O |

In conclusion, understanding the intricacies of zone control valve operations is essential for anyone involved in the design, installation, or maintenance of heating systems. These valves, while small and often overlooked, play a crucial role in maintaining the comfort and efficiency of our homes and offices. By controlling the distribution of heat in different zones, they allow for individual temperature settings, resulting in a level of comfort and energy efficiency that is not possible with a single thermostat system.

Exploring the Technical Details of Zone Control Valves

Zone control valves are an integral part of many industrial and residential systems, playing a crucial role in the regulation of fluid flow. These valves are designed to control the flow of water, gas, or other fluids within specific zones of a system, hence their name. Understanding the technical details of zone control valves can provide valuable insights into their operation, maintenance, and potential applications.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature |

| 2510 | 1.05″ (1″)O.D. | 1/2″O.D. | 1600-3/8″ | 2-1/2″-8NPSM | 72W | 1℃-43℃ |

| 1650-3/8″ |

A zone control valve is essentially a device that opens or closes to regulate the flow of fluid in a system. It is typically composed of a valve body, a valve stem, and a valve disc. The valve body provides a path for the fluid to flow through, while the valve stem and disc work together to control this flow. The valve stem is connected to an actuator, which can be manually operated or automatically controlled by a thermostat or other control device. When the actuator moves the valve stem, it causes the valve disc to either open or close, thereby controlling the flow of fluid.

One of the key technical details of zone control valves is their method of operation. There are two main types of zone control valves: two-way and three-way. Two-way zone control valves have two ports, an inlet and an outlet, and they work by either allowing or blocking the flow of fluid between these two ports. Three-way zone control valves, on the other hand, have three ports and can direct the flow of fluid in multiple directions. This makes them more versatile and suitable for more complex systems.

Another important technical detail of zone control valves is their size. The size of a zone control valve is typically determined by the diameter of the pipe it is designed to fit. This is usually measured in inches or millimeters, and it can range from less than an inch to several feet. The size of the valve is crucial because it determines the amount of fluid that can flow through it at any given time. Larger valves can handle higher flow rates, but they also require more force to operate and may be more difficult to install and maintain.

The material of the zone control valve is also a significant technical detail. Most zone control valves are made of metal, such as brass or stainless steel, because these materials are durable and resistant to corrosion. However, some valves are made of plastic or other materials, depending on the specific requirements of the system they are used in. For example, plastic valves may be used in systems that handle corrosive fluids, while metal valves may be used in high-pressure systems.

In conclusion, the technical details of zone control valves, including their method of operation, size, and material, are crucial to their function and performance. By understanding these details, one can make informed decisions about the selection, installation, and maintenance of these valves. Whether you are a homeowner looking to improve your heating system, or an engineer designing a complex industrial process, a thorough understanding of zone control valves can be invaluable.