Exploring the Impact of China’s Plastic Push on Connect Fittings

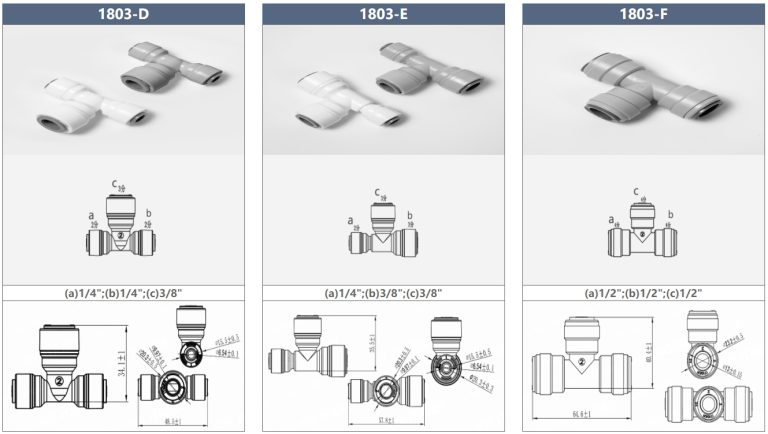

China’s recent emphasis on plastic push-to-connect fittings has sparked interest and discussions within the industry. These fittings, which allow for quick and easy installation without the need for specialized tools, have become increasingly popular due to their convenience and efficiency. However, with the UKCA certification now becoming a requirement for products entering the UK market, manufacturers and suppliers are facing new challenges and considerations.

The push-to-connect fittings, also known as push-fit fittings, have been widely used in various applications, including plumbing, heating, and air conditioning systems. Their simple design allows users to connect pipes or tubing by simply pushing them into the fitting, creating a secure and leak-proof connection. This ease of installation has made push-to-connect fittings a preferred choice for many contractors and DIY enthusiasts.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/33 |

In China, the production of push-to-connect fittings has been on the rise, with manufacturers catering to both domestic and international markets. The quality and reliability of these fittings have been a point of focus, with many Chinese companies investing in research and development to meet international standards and regulations. However, the recent requirement for UKCA certification has added a new layer of complexity to the production and distribution of these fittings.

The UKCA certification, which stands for UK Conformity Assessed, is now mandatory for products entering the UK market following the country’s departure from the European Union. This certification ensures that products meet specific safety, health, and environmental protection requirements set by the UK government. For manufacturers and suppliers in China, obtaining the UKCA certification for their push-to-connect fittings is crucial to continue exporting to the UK and maintaining market competitiveness.

The process of obtaining UKCA certification involves thorough testing and assessment of the product to ensure compliance with UK regulations. This includes evaluating the materials used, the design and construction of the fittings, and their performance under various conditions. Manufacturers must demonstrate that their push-to-connect fittings meet the required standards to receive the certification.

While the UKCA certification presents a challenge for Chinese manufacturers, it also offers an opportunity to demonstrate their commitment to quality and compliance with international standards. By obtaining the certification, manufacturers can enhance their reputation in the market and build trust with customers who prioritize safety and reliability in their products.

In conclusion, China’s plastic push-to-connect fittings industry is experiencing a shift due to the increasing demand for UKCA certification. This requirement underscores the importance of meeting international standards and regulations to access global markets. Manufacturers and suppliers in China must adapt to these changes by ensuring their push-to-connect fittings comply with the necessary requirements, thereby securing their position in the competitive market landscape.