Table of Contents

Pros and Cons of Using Push Fitting Connectors for Plumbing

Push fitting connectors have become a popular choice in plumbing due to their ease of use and affordability. These connectors offer a convenient way to join pipes without the need for soldering or specialized tools, making them a go-to option for DIY enthusiasts and professional plumbers alike.

One of the key advantages of push fitting connectors is their simplicity. With just a push and a click, these connectors create a secure and watertight seal, saving time and effort during installation. This ease of use makes them ideal for quick repairs or installations where efficiency is crucial.

In addition to their user-friendly nature, push fitting connectors are also versatile. They can be used with a variety of pipe materials, including copper, PEX, and CPVC, making them a flexible solution for different plumbing projects. This versatility eliminates the need for multiple types of connectors, simplifying the shopping process for consumers.

Another benefit of push fitting connectors is their reusability. Unlike traditional soldered connections, push fittings can be easily disconnected and reused if needed. This feature allows for greater flexibility during plumbing projects and reduces the likelihood of wasted materials.

Furthermore, push fitting connectors are known for their reliability. When installed correctly, these connectors create a strong and durable connection that can withstand high water pressure and temperature fluctuations. This reliability gives users peace of mind knowing that their plumbing system is secure and leak-free.

Despite their many advantages, push fitting connectors do have some limitations. One potential drawback is their compatibility with certain pipe materials. While push fittings are versatile, they may not work well with older or corroded pipes, requiring additional preparation or replacement of the pipes.

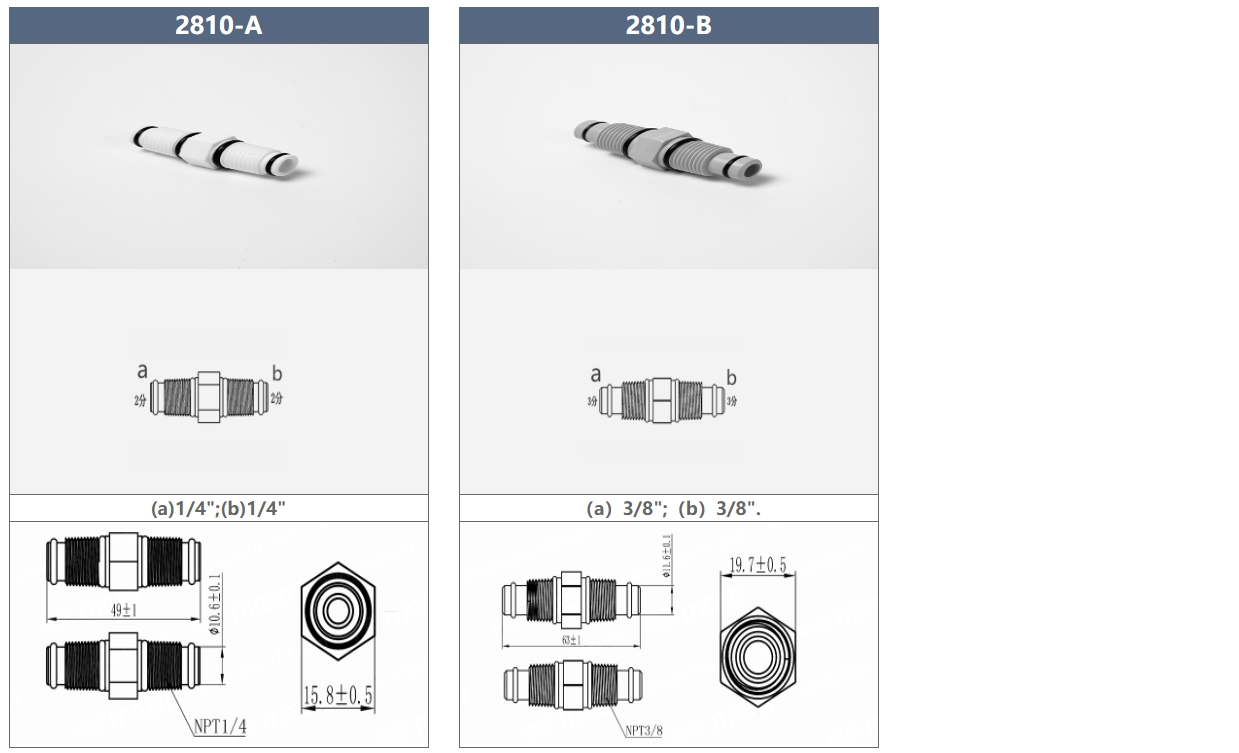

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/15 |

Another consideration is the cost of push fitting connectors. While they are generally affordable, the upfront cost of these connectors may be higher than traditional fittings. However, the time and labor saved during installation may offset this initial investment in the long run.

In conclusion, push fitting connectors offer a convenient and cost-effective solution for plumbing projects. Their ease of use, versatility, reusability, and reliability make them a popular choice among both DIYers and professionals. While they may have some limitations, such as compatibility issues and upfront costs, the benefits of push fitting connectors often outweigh these drawbacks. Whether you’re tackling a small repair or a major installation, consider using push fitting connectors for a hassle-free plumbing experience.

How to Install and Maintain Push Fitting Connectors for DIY Projects

Push fitting connectors are an essential component in many do-it-yourself (DIY) projects, offering a convenient and efficient way to connect pipes without the need for soldering or specialized tools. These connectors are widely used in plumbing, heating, and cooling systems, providing a reliable and leak-free connection. In this article, we will explore what push fitting connectors are, how to install them properly, and essential maintenance tips to ensure their longevity and effectiveness.

Push fitting connectors, also known as push-to-connect fittings, are designed to create a secure connection between pipes by simply pushing the pipe into the fitting. These connectors typically consist of three main components: the body, the grab ring, and the O-ring. The body of the fitting is responsible for holding the pipe in place, while the grab ring and O-ring provide a watertight seal. Push fitting connectors are available in various materials such as brass, copper, and plastic, making them suitable for different types of pipes and applications.

When it comes to installing push fitting connectors, the process is relatively straightforward. Start by cutting the pipe cleanly and squarely using a pipe cutter to ensure a proper fit. Remove any burrs or rough edges from the cut end of the pipe using a deburring tool. Next, insert the pipe into the fitting until it reaches the built-in stop. Make sure the pipe is fully inserted to ensure a secure connection. It is essential to check that the pipe is seated correctly by pulling on it gently.

One of the key advantages of push fitting connectors is their ease of installation, making them an ideal choice for DIY enthusiasts and professionals alike. Unlike traditional fittings that require soldering or threading, push fitting connectors can be installed quickly and easily without the need for specialized tools. This makes them a cost-effective and time-saving solution for various plumbing and heating projects.

To maintain the efficiency and longevity of push fitting connectors, regular inspection and maintenance are essential. Periodically check the fittings for any signs of leaks, corrosion, or damage. If you notice any issues, replace the fitting immediately to prevent further damage to the system. Additionally, ensure that the pipes are properly supported and secured to prevent stress on the fittings, which can lead to leaks over time.

In conclusion, push fitting connectors are a practical and affordable solution for connecting pipes in DIY projects. Their simple installation process, versatility, and durability make them a popular choice for a wide range of applications. By following the proper installation techniques and conducting regular maintenance, you can ensure that push fitting connectors provide a reliable and leak-free connection for years to come.