Understanding the Importance of Nuflo Flow Transmitter in Industrial Applications

In industrial applications, accurate measurement and control of flow rates are crucial for ensuring the efficiency and safety of processes. One of the key components used for this purpose is the Nuflo flow transmitter. Nuflo flow transmitters are widely used in various industries such as oil and gas, chemical, and water treatment, among others, due to their reliability and accuracy.

Nuflo flow transmitters are designed to measure the flow rate of liquids, gases, and steam in pipes and ducts. They utilize advanced technology to provide precise and real-time data on flow rates, allowing operators to monitor and control processes effectively. These transmitters come in different types, including electromagnetic, ultrasonic, and thermal mass flow meters, each suited for specific applications.

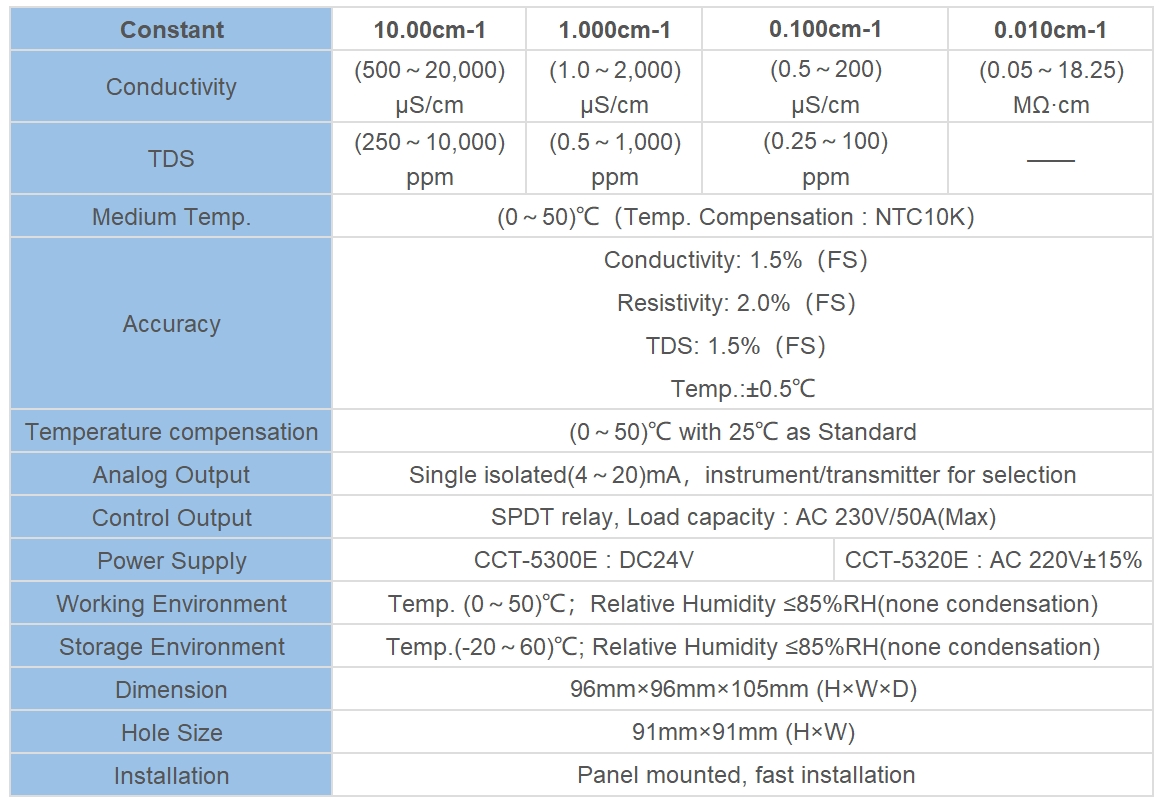

| Model | FL-9900 Paddle Wheel flow meter |

| Range | Flow Speed:0.5-5 m/s |

| Instantaneous Flow:0-2000m3/h | |

| Accuracy | Level 2 |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0\uff5e60\u2103; High temp 0\uff5e100\u2103 |

| Sensor | Paddle Wheel Sensor |

| Pipeline | DN20-DN300 |

| Communication | 4-20mA output/RS485 |

| Control | Instantaneous Flow High/Low alarm |

| Load Current 5A(Max) | |

| Power | 220V/110V/24V |

| Working Environment | Ambient temperature:0\uff5e50\u2103 |

| Relative humidity\u226485% | |

| Dimensions | 96\u00d796\u00d772mm(H\u00d7W\u00d7L) |

| Hole Size | 92\u00d792mm(H\u00d7W) |

| Installation Mode | Embedded |

One of the main advantages of using Nuflo flow transmitters is their high level of accuracy. These transmitters are calibrated to provide precise measurements, ensuring that operators can rely on the data they receive for making informed decisions. This accuracy is essential in industries where even small deviations in flow rates can have significant consequences on the overall process.

Furthermore, Nuflo flow transmitters are known for their durability and reliability. They are designed to withstand harsh operating conditions, such as high temperatures, pressure, and corrosive environments, making them ideal for use in industrial settings. This reliability ensures that the transmitters can continue to provide accurate measurements over an extended period, reducing the need for frequent maintenance and replacement.

In addition to their accuracy, reliability, and versatility, Nuflo flow transmitters also offer advanced features that enhance their performance. These features include digital displays, communication interfaces, and data logging capabilities, allowing operators to access and analyze flow data easily. Some transmitters also come with diagnostic tools that help identify potential issues and ensure that the system is operating efficiently.

Overall, Nuflo flow transmitters play a crucial role in industrial applications by providing accurate and reliable measurements of flow rates. Their advanced technology, durability, and versatility make them an essential component in processes where precise control of flow rates is necessary. By investing in Nuflo flow transmitters, industries can improve efficiency, reduce downtime, and ensure the safety of their operations.

In conclusion, understanding the importance of Nuflo flow transmitters in industrial applications is essential for ensuring the efficiency and reliability of processes. These transmitters offer a range of benefits, including accuracy, reliability, versatility, and advanced features, making them a valuable tool for monitoring and controlling flow rates. By utilizing Nuflo flow transmitters, industries can optimize their operations and achieve better outcomes in terms of productivity and safety.