Table of Contents

Importance of Regular Maintenance for Flow Sensors

Flow sensors are crucial components in various industries, including manufacturing, pharmaceuticals, and water treatment. These sensors measure the flow rate of liquids or gases in a system, providing valuable data for process control and monitoring. However, like any other equipment, flow sensors require regular maintenance to ensure accurate and reliable performance.

One common issue that can arise with flow sensors is inoperability. When a flow sensor is not functioning properly, it can lead to inaccurate measurements, which can have serious consequences for the overall operation of a system. For example, in a water treatment plant, a malfunctioning flow sensor could result in improper dosing of chemicals, leading to ineffective treatment of water and potential health risks.

Regular maintenance of flow sensors is essential to prevent such issues. By conducting routine inspections and calibrations, operators can identify and address any potential problems before they escalate. This proactive approach not only ensures the accuracy of flow measurements but also extends the lifespan of the sensor, saving time and money in the long run.

One of the most common reasons for flow sensor inoperability is the accumulation of debris or buildup on the sensor element. Over time, dirt, dust, or other contaminants can obstruct the flow path, causing the sensor to malfunction. Regular cleaning of the sensor element is necessary to prevent this buildup and maintain optimal performance.

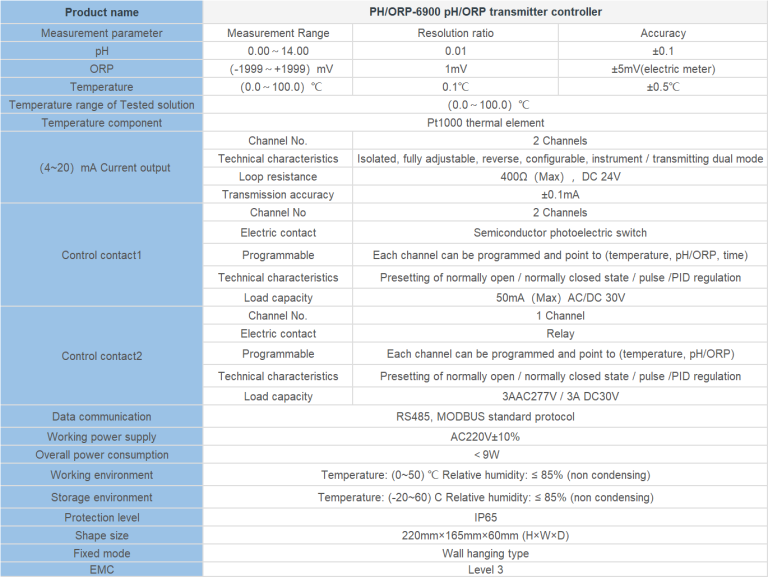

| Product name | PH/ORP-6900 pH/ORP transmitter controller | ||

| Measurement parameter | Measurement Range | Resolution ratio | Accuracy |

| pH | 0.00\uff5e14.00 | 0.01 | \u00b10.1 |

| ORP | \uff08-1999\uff5e+1999\uff09mV | 1mV | \u00b15mV(electric meter) |

| Temperature | \uff080.0\uff5e100.0\uff09\u2103 | 0.1\u2103 | \u00b10.5\u2103 |

| Temperature range of Tested solution | \uff080.0\uff5e100.0\uff09\u2103 | ||

| Temperature component | Pt1000 thermal element | ||

| \uff084~20\uff09mA Current output | Channel No. | 2 Channels | |

| Technical characteristics | Isolated, fully adjustable, reverse, configurable, instrument / transmitting dual mode | ||

| Loop resistance | 400\u03a9\uff08Max\uff09\uff0cDC 24V | ||

| Transmission accuracy | \u00b10.1mA | ||

| Control contact1 | Channel No | 2 Channels | |

| Electric contact | Semiconductor photoelectric switch | ||

| Programmable | Each channel can be programmed and point to (temperature, pH/ORP, time) | ||

| Technical characteristics | Presetting of normally open / normally closed state / pulse /PID regulation | ||

| Load capacity | 50mA\uff08Max\uff09AC/DC 30V | ||

| Control contact2 | Channel No. | 1 Channel | |

| Electric contact | Relay | ||

| Programmable | Each channel can be programmed and point to (temperature, pH/ORP) | ||

| Technical characteristics | Presetting of normally open / normally closed state / pulse /PID regulation | ||

| Load capacity | 3AAC277V / 3A DC30V | ||

| Data communication | RS485, MODBUS standard protocol | ||

| Working power supply | AC220V\u00b110% | ||

| Overall power consumption | \uff1c9W | ||

| Working environment | Temperature: (0~50) \u2103 Relative humidity: \u2264 85% (non condensing) | ||

| Storage environment | Temperature: (-20~60) C Relative humidity: \u2264 85% (non condensing) | ||

| Protection level | IP65 | ||

| Shape size | 220mm\u00d7165mm\u00d760mm (H\u00d7W\u00d7D) | ||

| Fixed mode | Wall hanging type | ||

| EMC | Level 3 | ||

In addition to cleaning, calibration is another critical aspect of flow sensor maintenance. Calibration involves adjusting the sensor to ensure that it provides accurate measurements within a specified range. Regular calibration helps to maintain the accuracy and reliability of the sensor, allowing operators to trust the data it provides.

Another important maintenance task for flow sensors is checking for leaks or damage to the sensor housing. Any cracks or leaks in the housing can compromise the integrity of the sensor and lead to inaccurate readings. By inspecting the sensor housing regularly, operators can identify and repair any issues before they impact the sensor’s performance.

Furthermore, regular maintenance of flow sensors includes checking the electrical connections and wiring. Loose connections or damaged wires can cause the sensor to malfunction or provide erratic readings. By inspecting the electrical components of the sensor, operators can ensure that it is properly connected and functioning correctly.

Overall, the importance of regular maintenance for flow sensors cannot be overstated. By conducting routine inspections, cleaning, calibration, and checks of the sensor housing and electrical connections, operators can prevent inoperability issues and ensure the accuracy and reliability of flow measurements. Investing time and resources in maintenance now can save time and money in the long run by avoiding costly repairs or replacements due to sensor failure. In conclusion, regular maintenance is essential for the optimal performance of flow sensors and the overall efficiency of industrial processes.

Troubleshooting Common Issues with Flow Sensors

Flow sensors are essential components in many industrial processes, helping to measure the flow rate of liquids or gases. However, like any piece of equipment, flow sensors can experience issues that may affect their performance. One common problem that users may encounter is a flow sensor that is inoperative, or not functioning properly. In this article, we will explore some of the potential causes of this issue and provide troubleshooting tips to help resolve it.

One possible reason for a flow sensor being inoperative is a blockage in the flow path. Over time, debris or buildup can accumulate in the sensor, obstructing the flow of the liquid or gas being measured. This can lead to inaccurate readings or a complete failure of the sensor. To address this issue, it is important to regularly inspect and clean the flow sensor to ensure that the flow path is clear.

Another potential cause of a flow sensor being inoperative is a faulty electrical connection. If the wiring connecting the sensor to the control system is damaged or loose, the sensor may not be able to transmit accurate data. In this case, it is important to check the wiring and connections to ensure that they are secure and functioning properly. If any issues are found, they should be repaired or replaced as needed.

In some cases, a flow sensor may be inoperative due to a calibration error. If the sensor is not calibrated correctly, it may not be able to accurately measure the flow rate of the liquid or gas. To address this issue, it is important to recalibrate the sensor according to the manufacturer’s instructions. This may involve adjusting the settings on the sensor or using a calibration tool to ensure accurate readings.

Additionally, a flow sensor may be inoperative due to a mechanical failure. If the internal components of the sensor are damaged or worn out, it may not be able to function properly. In this case, the sensor may need to be repaired or replaced to restore its functionality. It is important to regularly inspect the sensor for any signs of wear or damage and address any issues promptly to prevent further problems.

In conclusion, a flow sensor that is inoperative can be a frustrating issue for users. However, by understanding some of the potential causes of this problem and following the troubleshooting tips provided in this article, users can effectively address the issue and restore the functionality of their flow sensor. Regular maintenance, inspection, and calibration are key to ensuring that flow sensors continue to operate effectively and provide accurate measurements. By taking proactive steps to address any issues that arise, users can minimize downtime and ensure the reliable performance of their flow sensors.