Table of Contents

Benefits of Using a 1700 brine valve in Water Softening Systems

Water softening systems are essential for removing minerals such as calcium and magnesium from hard water, which can cause damage to pipes and appliances. One crucial component of a water softening system is the brine valve, which is responsible for regulating the flow of brine solution during the regeneration process. The 1700 brine valve is a popular choice among homeowners and businesses due to its efficiency and reliability.

One of the main benefits of using a 1700 brine valve in a water softening system is its durability. Made from high-quality materials, such as stainless steel and corrosion-resistant plastics, the 1700 brine valve is designed to withstand the harsh conditions of a water softening system. This means that it will last longer and require less maintenance compared to other types of brine valves.

In addition to its durability, the 1700 brine valve is also known for its efficiency. With its precise control over the flow of brine solution, the 1700 brine valve ensures that the regeneration process is carried out effectively, resulting in softer water for your home or business. This efficiency not only saves you time and money but also helps to prolong the life of your water softening system.

Another advantage of using a 1700 brine valve is its versatility. Whether you have a small residential water softening system or a large commercial one, the 1700 brine valve can be easily adapted to suit your needs. With its adjustable settings and customizable features, the 1700 brine valve can be tailored to meet the specific requirements of your water softening system.

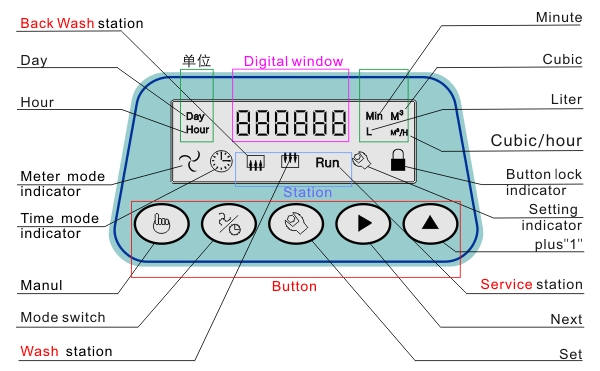

Furthermore, the 1700 brine valve is easy to install and operate, making it a convenient choice for homeowners and businesses alike. With its user-friendly design and clear instructions, the 1700 brine valve can be set up quickly and easily, allowing you to start enjoying the benefits of soft water in no time. Additionally, the 1700 brine valve is low maintenance, requiring minimal attention to keep it running smoothly.

| Model | AFC2-LCD | AFC2-LED |

| Working Position | Filter->Back wash 1->Back wash 2-> Fast rinse -> Filter\u00a0 | |

| Regeneration mode | Automatic\u00a0 | Automatic\u00a0 |

| Time by day :0-99days | Time by day :0-99days | |

| Time by hours:0-99 hours | Time by hours:0-99 hours | |

| In (inlet of valve) | 1/2”F | 1/2”F |

| I1(inlet of first filter) | 1/2”F | 1/2”F |

| I2(inlet of second filter) | 1/2”F | 1/2”F |

| Drain | 1/2”M | 1/2”M |

| D1( Drain of first filter) | 1/2”M | 1/2”M |

| D2(Drain of second filter) | 1/2”M | 1/2”M |

| Water capacity\u00a0 | 2m3/h | 2m3/h |

| Working pressure | 0.15-0.6Mpa | |

| Power Supply\u00a0 | AC100-240V/ 50-60Hz \u00a0 \u00a0 \u00a0/ \u00a0 \u00a0DC12V-1.5A | |

Overall, the 1700 brine valve offers a range of benefits for those looking to improve the efficiency and effectiveness of their water softening system. From its durability and efficiency to its versatility and ease of use, the 1700 brine valve is a reliable choice for homeowners and businesses alike. By investing in a 1700 brine valve, you can ensure that your water softening system operates at its best, providing you with soft, clean water for years to come.

How to Troubleshoot Common Issues with a 1700 brine valve

The 1700 brine valve is a crucial component of a water softener system, responsible for regulating the flow of brine during the regeneration process. Like any mechanical device, the 1700 brine valve can experience issues that may affect its performance. In this article, we will discuss some common problems that may arise with a 1700 brine valve and how to troubleshoot them effectively.

One of the most common issues with a 1700 brine valve is a blockage in the valve body. This can occur due to the buildup of sediment or debris in the valve, preventing it from opening and closing properly. To address this issue, the first step is to shut off the water supply to the water softener system and disconnect the brine line from the valve. Next, remove the valve body from the system and inspect it for any signs of blockage. If you notice any buildup, clean the valve thoroughly using a mild detergent and a soft brush. Once the valve body is clean, reassemble the valve and reconnect the brine line. Turn the water supply back on and check to see if the issue has been resolved.

Another common problem with a 1700 brine valve is a faulty solenoid. The solenoid is responsible for opening and closing the valve, allowing brine to flow into the resin tank during regeneration. If the solenoid is not functioning properly, the valve may not open or close as it should, leading to issues with the regeneration process. To troubleshoot a faulty solenoid, start by checking the electrical connections to ensure they are secure. If the connections are intact, test the solenoid using a multimeter to determine if it is receiving power. If the solenoid is not receiving power, it may need to be replaced to resolve the issue.

In some cases, a 1700 brine valve may experience leaks, which can lead to water waste and potential damage to the surrounding area. Leaks can occur due to a variety of reasons, such as worn seals or damaged components. To troubleshoot a leaky brine valve, start by inspecting the valve for any visible signs of damage, such as cracks or corrosion. If you identify any damaged components, replace them as needed to prevent further leaks. Additionally, check the seals on the valve to ensure they are in good condition. If the seals are worn or damaged, replace them to create a tight seal and prevent leaks from occurring.

Overall, troubleshooting common issues with a 1700 brine valve requires a systematic approach to identify and address the root cause of the problem. By following the steps outlined in this article, you can effectively troubleshoot issues with your brine valve and ensure that your water softener system operates efficiently. Remember to always consult the manufacturer’s guidelines and seek professional assistance if needed to resolve complex issues with your 1700 brine valve.