Preventing leaks, preserving performance: the role of valve seals.

Understanding the Function of Valve Seals in an Engine

Valve seals are a crucial component in an engine that often goes unnoticed by many drivers. These small but important parts play a significant role in ensuring the proper functioning of the engine. In this article, we will delve into the intricacies of valve seals and how they work to maintain the efficiency and performance of an engine.

Valve seals are located at the top of the valve stem and are designed to prevent oil from leaking into the combustion chamber. This is important because oil in the combustion chamber can lead to a decrease in engine performance and efficiency. Valve seals are typically made of rubber or metal and are designed to create a tight seal around the valve stem to prevent oil from seeping through.

When the engine is running, the valve seals are constantly exposed to high temperatures and pressure. This can cause the seals to wear out over time, leading to oil leaks and decreased engine performance. It is important to regularly inspect and replace valve seals to ensure the proper functioning of the engine.

Valve seals work by creating a barrier between the valve stem and the valve guide. This prevents oil from leaking into the combustion chamber and ensures that the engine runs smoothly and efficiently. Without proper valve seals, oil can leak into the combustion chamber and cause a host of issues, including decreased engine performance, increased emissions, and potential damage to the engine.

In addition to preventing oil leaks, valve seals also help to maintain proper lubrication of the valve stem. This is important because the valve stem moves up and down rapidly during the engine’s operation, and proper lubrication is essential to prevent wear and tear on the valve stem and valve guide. Valve seals help to ensure that the valve stem remains properly lubricated, which in turn helps to prolong the life of the engine.

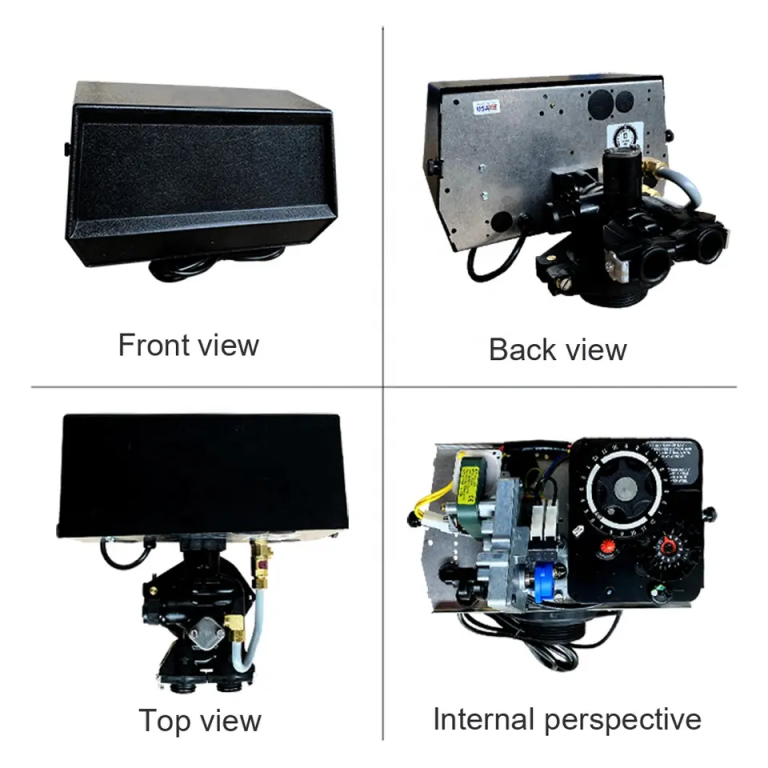

| Model: Automatic softener Valve | ASDU2 -LCD/LED |

| Working Position | Service->Back Wash->Downflow Brine and slow rinse->Refill -> Fast rinse->Service. |

| Service->Back Wash->Upflow Brine and slow rinse->Refill -> Fast rinse->Service. | |

| Regeneration mode | Automatic type |

| Meter Delay | |

| Meter immediate | |

| Intelligent Meter Delay | |

| Intelligent Meter Immediate | |

| Timer by day : 0-99 days | |

| Timer by hours: 0-99 hours | |

| Inlet | 1/2” 3/4” 1” |

| Outlet | 1/2” 3/4” 1” |

| Drain | 1/2” |

| Base | 2-1/2” |

| Riser pipe | 1.05” OD |

| Water Capacity | 2m3/h |

| Working Pressure | 0.15-0.6Mpa |

| Working Temperature | 5-50 °C |

| Power Supply | AC100-240 / 50-60Hz / DC12V-1.5A |

Valve seals also play a role in controlling the flow of oil within the engine. By creating a tight seal around the valve stem, valve seals help to regulate the amount of oil that enters the combustion chamber. This is important because too much oil in the combustion chamber can lead to a decrease in engine performance and efficiency. Valve seals help to maintain the proper balance of oil within the engine, ensuring that it runs smoothly and efficiently.

In conclusion, valve seals are a critical component in an engine that plays a key role in maintaining the efficiency and performance of the engine. By creating a tight seal around the valve stem, valve seals prevent oil from leaking into the combustion chamber and help to regulate the flow of oil within the engine. Regular inspection and replacement of valve seals are essential to ensure the proper functioning of the engine and to prevent issues such as decreased engine performance and increased emissions. Understanding how valve seals work is essential for any driver who wants to keep their engine running smoothly and efficiently.