“Flexible PVC conduit fittings: Bend it, shape it, protect your wiring with ease.”

Table of Contents

Benefits of Using Flexible PVC Conduit Fittings in Electrical Installations

Flexible PVC conduit fittings are an essential component in electrical installations, providing numerous benefits that make them a popular choice among electricians and contractors. These fittings are designed to protect and route electrical wiring in a safe and efficient manner, ensuring that the electrical system functions properly and remains secure. In this article, we will explore the various benefits of using flexible PVC conduit fittings in electrical installations.

One of the primary advantages of flexible PVC conduit fittings is their flexibility and durability. Unlike rigid metal conduit fittings, flexible PVC fittings can be easily bent and maneuvered to fit around obstacles and corners, making them ideal for installations in tight spaces or areas with complex layouts. This flexibility also allows for easier installation and maintenance, saving time and effort for electricians and contractors.

In addition to their flexibility, flexible PVC conduit fittings are also highly durable and resistant to corrosion, moisture, and chemicals. This makes them suitable for use in a wide range of environments, including outdoor installations where exposure to the elements is a concern. The durability of PVC fittings ensures that the electrical system remains protected and secure, even in harsh conditions.

Another benefit of using flexible PVC conduit fittings is their cost-effectiveness. PVC fittings are generally more affordable than metal fittings, making them a budget-friendly option for electrical installations. Additionally, the ease of installation and maintenance of PVC fittings can help reduce labor costs, further adding to their cost-effectiveness.

Furthermore, flexible PVC conduit fittings are lightweight and easy to handle, making them convenient to work with during installations. Their smooth surface also allows for easy pulling of wires through the conduit, reducing the risk of damage to the wires and ensuring a smooth and efficient installation process.

In terms of safety, flexible PVC conduit fittings are non-conductive and do not rust or corrode, reducing the risk of electrical hazards and ensuring the longevity of the electrical system. PVC fittings are also flame-retardant, providing an added layer of protection in the event of a fire.

Additionally, flexible PVC conduit fittings are available in a variety of sizes and configurations to accommodate different types of electrical wiring and installations. This versatility makes PVC fittings suitable for a wide range of applications, from residential to commercial and industrial settings.

Overall, the benefits of using flexible PVC conduit fittings in electrical installations are numerous. From their flexibility and durability to their cost-effectiveness and safety features, PVC fittings offer a reliable and efficient solution for protecting and routing electrical wiring. Whether you are a professional electrician or a DIY enthusiast, flexible PVC conduit fittings are a practical choice for ensuring the success and safety of your electrical projects.

How to Properly Install and Maintain Flexible PVC Conduit Fittings

Flexible PVC conduit fittings are an essential component in electrical installations, providing a protective housing for wires and cables while allowing for easy access and maintenance. Proper installation and maintenance of these fittings are crucial to ensure the safety and efficiency of the electrical system. In this article, we will discuss the steps involved in installing and maintaining flexible PVC conduit fittings to help you get the most out of your electrical system.

When it comes to installing flexible PVC conduit fittings, the first step is to carefully plan the layout of the conduit system. This involves determining the route the conduit will take, the number of fittings needed, and the size of the conduit required. It is important to ensure that the conduit is properly sized to accommodate the wires and cables that will be running through it, as using an undersized conduit can lead to overheating and potential fire hazards.

Once the layout has been planned, the next step is to cut the conduit to the desired length using a PVC pipe cutter or hacksaw. It is important to make clean, straight cuts to ensure a proper fit with the fittings. After cutting the conduit, remove any burrs or rough edges using a deburring tool or sandpaper to prevent damage to the wires during installation.

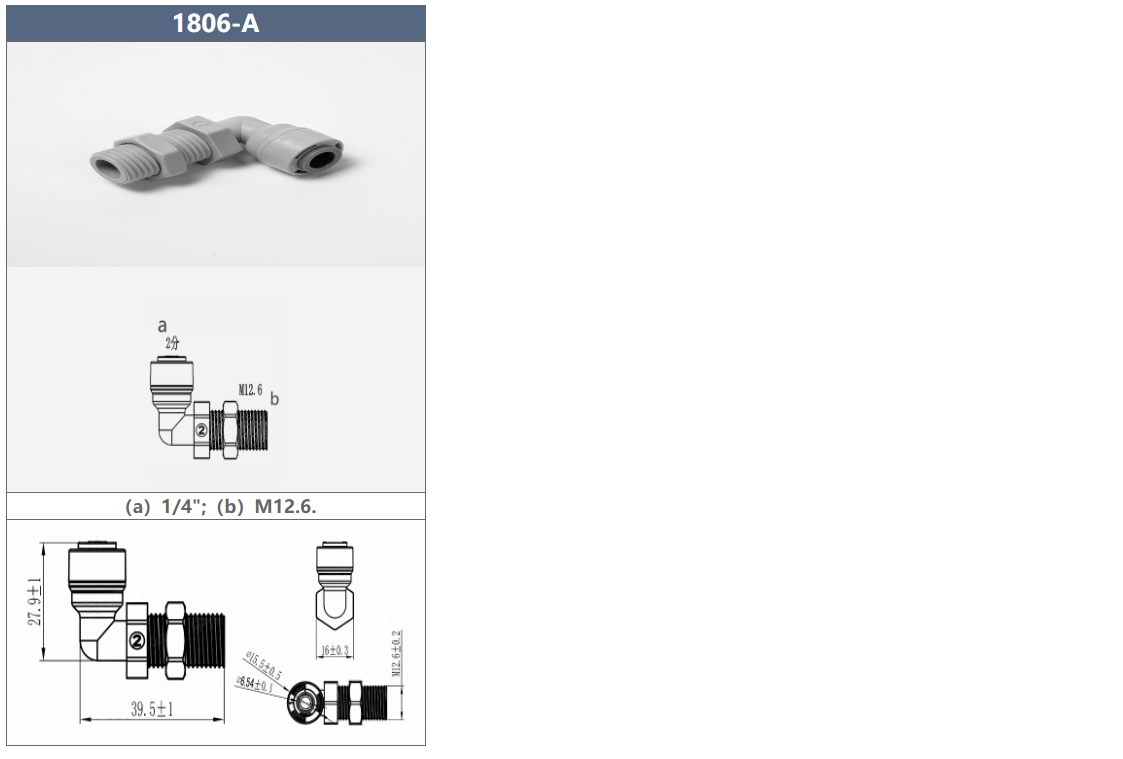

| Model | Stem (a) |

Stem (b) |

Tube (c) |

| 1800-A | 1/4 | 1/4 | – |

| 1800-B | 1/4 | 1/4 | Short |

| 1800-D | 1/2 | 1/2 | Short |

With the conduit cut to size, the next step is to install the fittings. Start by inserting the wires and cables into the conduit, making sure to leave enough slack for future maintenance or repairs. Next, slide the fittings onto the conduit and secure them in place using PVC cement or a compression fitting, depending on the type of fitting being used. Make sure to follow the manufacturer’s instructions for proper installation to ensure a secure and watertight connection.

After the fittings have been installed, it is important to properly secure the conduit to the wall or ceiling using appropriate fasteners. This will help prevent the conduit from sagging or coming loose over time, which can lead to damage to the wires and cables inside. Make sure to use the correct type and size of fasteners for the job, and space them evenly along the length of the conduit for maximum support.

Once the conduit system is installed, it is important to regularly inspect and maintain it to ensure its continued performance and safety. This includes checking for any signs of damage, such as cracks, dents, or corrosion, which can compromise the integrity of the conduit and fittings. If any damage is found, it should be repaired or replaced immediately to prevent further issues.

In addition to visual inspections, it is also important to periodically clean the conduit and fittings to remove any dirt, dust, or debris that can accumulate over time. This can be done using a mild detergent and water, or a specialized PVC cleaner, depending on the level of dirt and grime present. Regular cleaning will help prevent blockages and ensure that the conduit system continues to function properly.

In conclusion, proper installation and maintenance of flexible PVC conduit fittings are essential for the safety and efficiency of an electrical system. By following the steps outlined in this article, you can ensure that your conduit system is installed correctly and maintained properly for years to come. Remember to plan the layout carefully, cut the conduit to size, install the fittings securely, and regularly inspect and clean the system to keep it in top condition.