“Plastic CGB connectors: reliable, durable, and versatile.”

Benefits of Using Plastic CGB Connectors in Industrial Applications

Plastic CGB connectors, also known as cord grips or cable glands, are essential components in industrial applications where cables need to be securely connected to equipment or enclosures. These connectors are designed to provide strain relief, prevent cable pullout, and protect cables from environmental factors such as dust, moisture, and chemicals. While metal CGB connectors have been traditionally used in industrial settings, plastic CGB connectors offer several benefits that make them a popular choice for many applications.

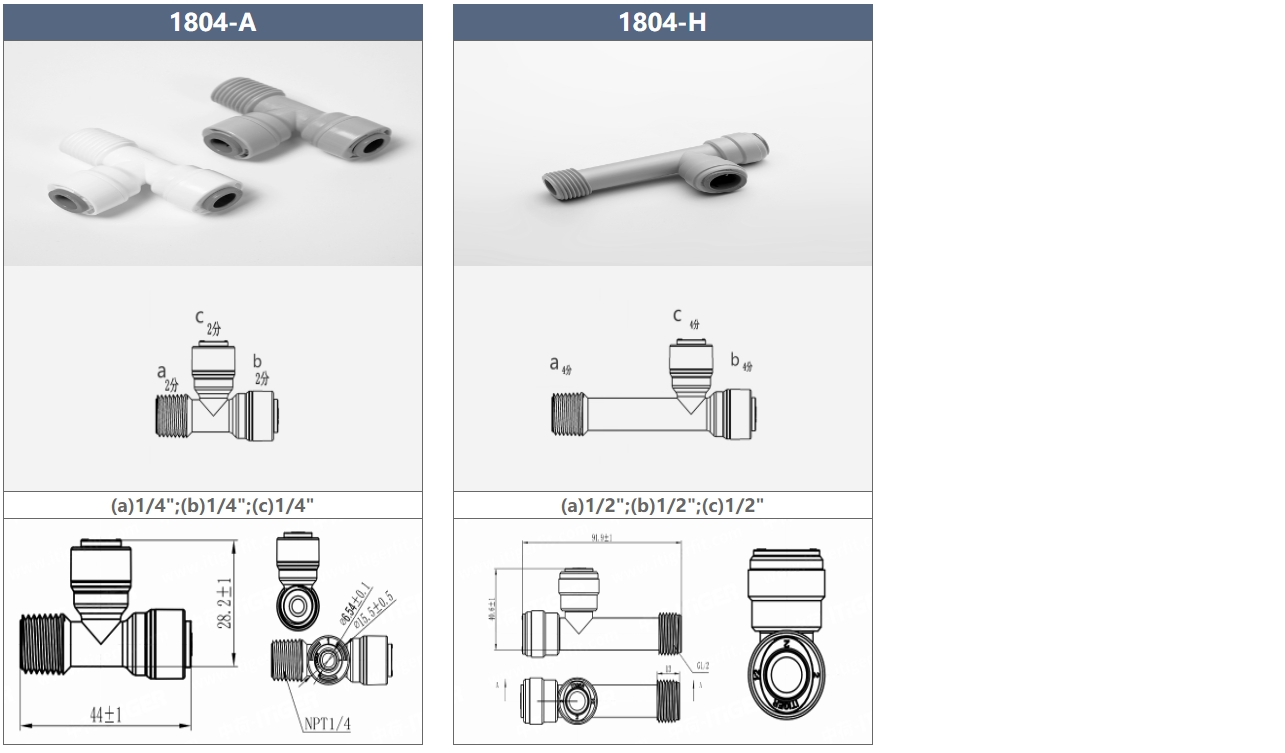

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/44 |

One of the key advantages of using plastic CGB connectors is their lightweight and corrosion-resistant properties. Unlike metal connectors, plastic CGB connectors are not susceptible to rust or corrosion, making them ideal for use in outdoor or harsh environments where exposure to moisture or chemicals is a concern. Additionally, the lightweight nature of plastic connectors makes them easier to handle and install, reducing the risk of strain or injury for workers.

Another benefit of plastic CGB connectors is their cost-effectiveness. Plastic connectors are typically more affordable than their metal counterparts, making them a budget-friendly option for industrial applications that require multiple connectors. Despite their lower cost, plastic CGB connectors are still durable and reliable, providing a secure connection for cables without compromising on quality.

In addition to their cost-effectiveness, plastic CGB connectors are also versatile in terms of compatibility with different cable sizes and types. These connectors are available in various sizes and configurations to accommodate a wide range of cable diameters, making them suitable for use with different types of cables, including armored, non-armored, and flexible cables. This versatility allows for greater flexibility in designing and implementing cable management systems in industrial settings.

Furthermore, plastic CGB connectors are easy to install and maintain, requiring minimal tools and expertise. The simple design of these connectors allows for quick and hassle-free installation, saving time and labor costs for industrial operations. Additionally, plastic connectors are easy to clean and maintain, requiring only periodic inspections to ensure proper functioning and safety.

Despite their many benefits, it is important to note that plastic CGB connectors may not be suitable for all industrial applications. In environments where extreme temperatures, high pressure, or heavy mechanical stress are present, metal connectors may be a more suitable option due to their higher durability and resistance to harsh conditions. It is essential to consider the specific requirements of the application and consult with a professional to determine the most appropriate connector type for the job.

In conclusion, plastic CGB connectors offer several advantages that make them a practical choice for many industrial applications. Their lightweight, corrosion-resistant, cost-effective, and versatile properties make them an attractive option for cable management in a variety of settings. While metal connectors may be more suitable for certain demanding environments, plastic CGB connectors provide a reliable and efficient solution for many industrial applications. By understanding the benefits and limitations of plastic CGB connectors, businesses can make informed decisions when selecting connectors for their cable management needs.