“Protect your wires with PVC electrical conduit.”

Pros and Cons of Using PVC Electrical Conduit

PVC electrical conduit is a popular choice for protecting and routing electrical wiring in residential, commercial, and industrial settings. It is made of polyvinyl chloride, a durable and lightweight material that is resistant to corrosion, chemicals, and moisture. PVC conduit is easy to install, cost-effective, and provides excellent protection for electrical wires. However, there are certain situations where PVC conduit may not be the best choice. In this article, we will discuss the pros and cons of using PVC electrical conduit and when it is appropriate to use this type of conduit.

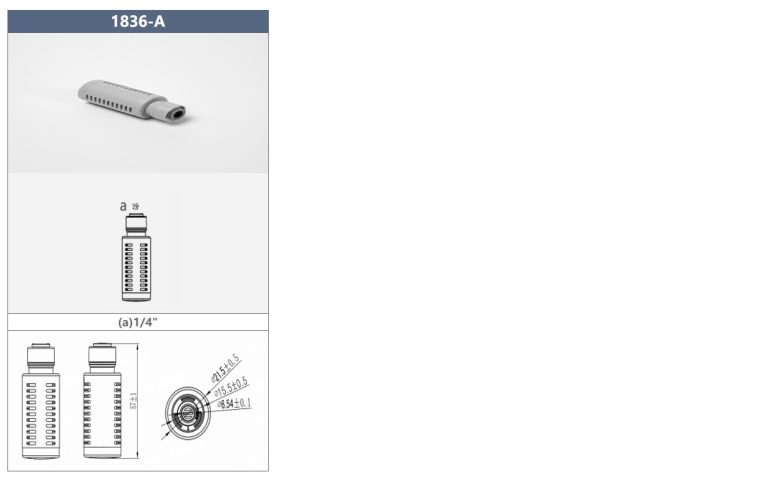

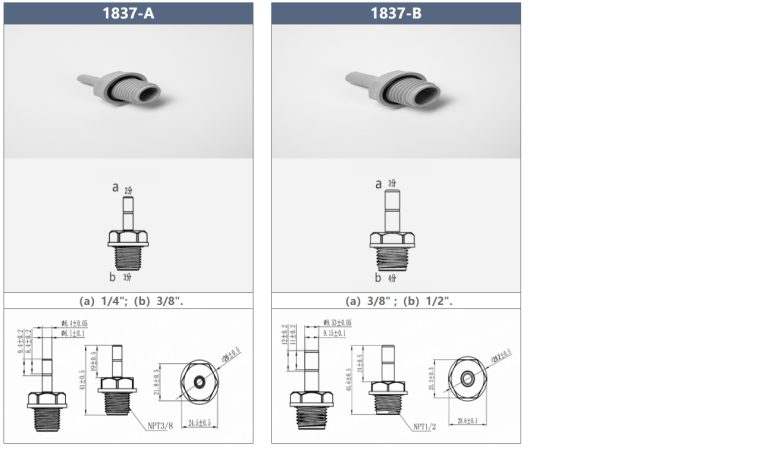

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/28 |

One of the main advantages of PVC electrical conduit is its ease of installation. PVC conduit is lightweight and flexible, making it easy to cut and bend to fit around obstacles. It can be easily joined together using PVC cement, which creates a strong and watertight seal. This makes PVC conduit a popular choice for DIY enthusiasts and professional electricians alike.

Another benefit of PVC electrical conduit is its cost-effectiveness. PVC conduit is relatively inexpensive compared to other types of conduit, such as metal or fiberglass. This can result in significant cost savings, especially for large-scale electrical projects. Additionally, PVC conduit is durable and long-lasting, which means it will not need to be replaced as frequently as other types of conduit.

PVC electrical conduit is also resistant to corrosion, chemicals, and moisture. This makes it an ideal choice for outdoor applications or in areas where the conduit may be exposed to harsh conditions. PVC conduit is also non-conductive, which means it will not conduct electricity and poses less of a risk of electrical shock.

Despite its many advantages, there are some situations where PVC electrical conduit may not be the best choice. One of the main drawbacks of PVC conduit is its limited temperature range. PVC conduit is not suitable for use in high-temperature environments, as it can become brittle and crack when exposed to extreme heat. In these situations, metal conduit may be a better option.

Another potential downside of PVC electrical conduit is its lack of impact resistance. PVC conduit can be easily damaged if it is struck or crushed, which can lead to exposed wires and potential safety hazards. In areas where the conduit is at risk of being damaged, such as in high-traffic areas or in industrial settings, metal or fiberglass conduit may be a better choice.

In conclusion, PVC electrical conduit is a versatile and cost-effective option for protecting and routing electrical wiring. It is easy to install, durable, and resistant to corrosion, chemicals, and moisture. However, there are certain situations where PVC conduit may not be the best choice, such as in high-temperature environments or in areas where the conduit is at risk of being damaged. By considering the pros and cons of using PVC electrical conduit, you can make an informed decision about whether it is the right choice for your electrical project.