Table of Contents

Understanding the Functionality of Fleck Control Valves

Fleck control valves are an integral part of water treatment systems, playing a pivotal role in the regulation and management of water flow. These valves are renowned for their durability, efficiency, and ease of use, making them a popular choice for both residential and commercial applications. Understanding the functionality of Fleck control valves can provide valuable insights into their operation and maintenance, ensuring optimal performance and longevity.

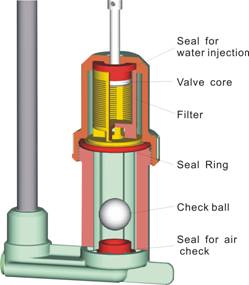

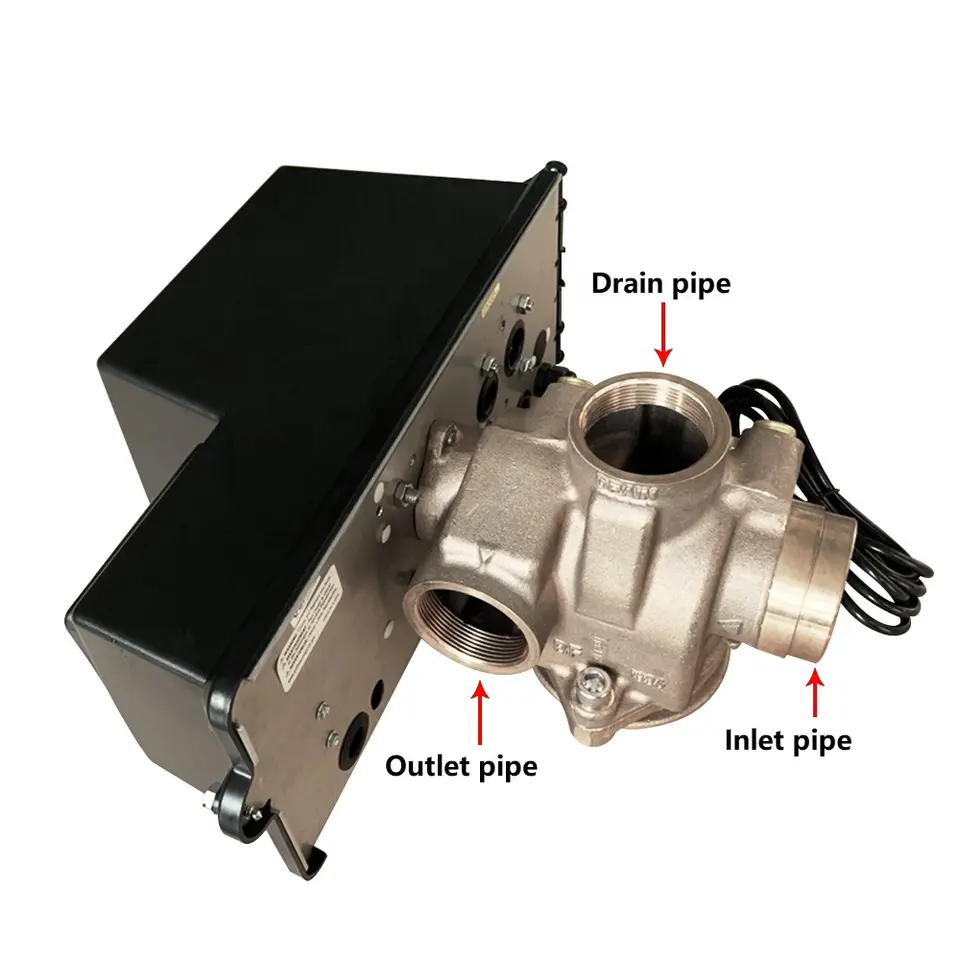

Fleck control valves are essentially the brain of a water treatment system. They control the flow of water through the system, directing it to the appropriate areas for filtration or softening. The valves are designed to automatically manage the entire process, from backwashing and rinsing to brining and service. This automation not only simplifies the operation of the water treatment system but also enhances its efficiency by ensuring that each process is carried out at the right time and in the correct sequence.

The operation of Fleck control valves is based on a timer or a meter. Timer-based valves initiate the regeneration process at preset intervals, regardless of the amount of water used. This type of valve is ideal for applications where water usage is consistent. On the other hand, meter-based valves trigger the regeneration process based on the volume of water used. This ensures that the system regenerates only when necessary, conserving water and salt. Meter-based valves are particularly beneficial for applications where water usage varies.

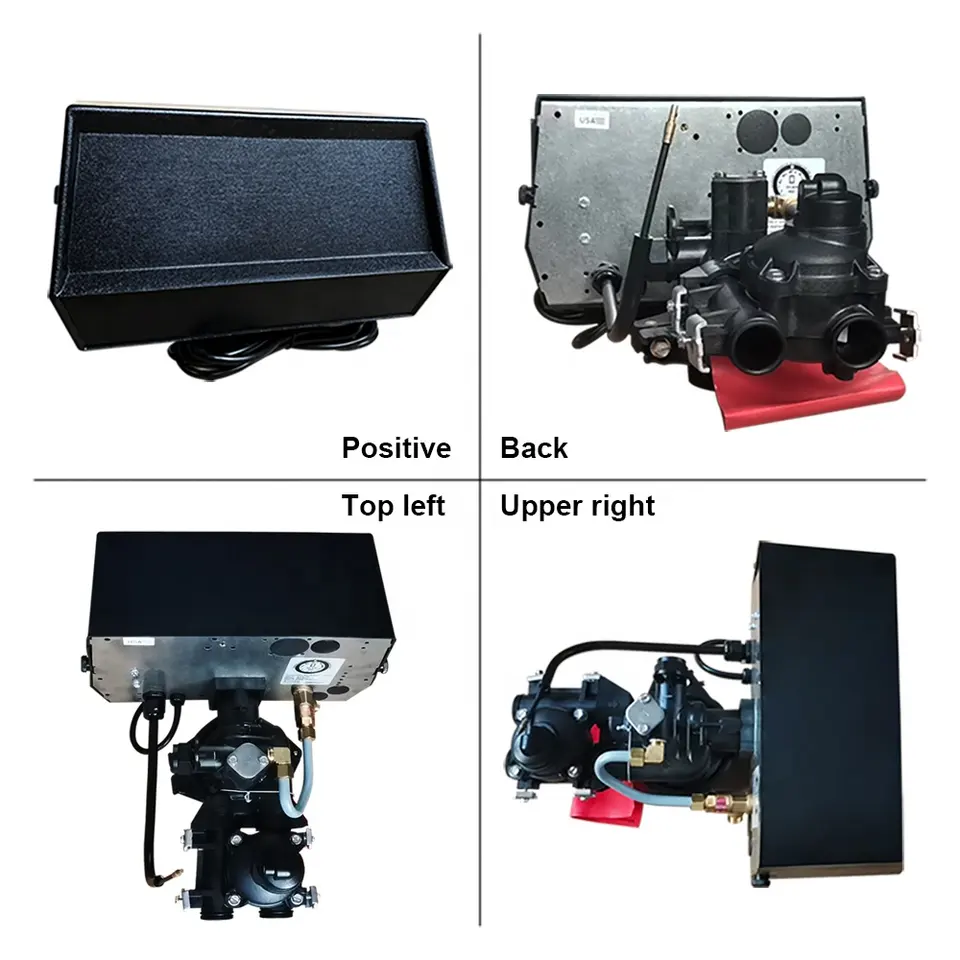

One of the distinguishing features of Fleck control valves is their robust construction. They are built to withstand the rigors of continuous operation, ensuring reliable performance over an extended period. The valves are made from high-quality materials that resist wear and tear, and they are designed to be easy to service, with replaceable parts that can be quickly swapped out when necessary.

| Model | MSD2 | MSD4 | MSD4-B | MSD10 | ASD2 -LCD/LED | ASD4-LCD/LED | ASD10-LED |

| Working Position | Service->Back wash->Brine and slow rinse->Fast rinse->Refill->Service | ||||||

| Regeneration mode | Manual | Automatic | |||||

| Inlet | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1/2”, 3/4”, 1” | 2” |

| Outlet | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1/2”, 3/4”, 1” | 2” |

| Drain | 1/2” | 1/2” | 1/2” | 1” | 1/2” | 1/2” | 1” |

| Base | 2-1/2” | 2-1/2” | 2-1/2” | 4” | 2-1/2” | 2-1/2” | 4” |

| Riser pipe | 1.05”OD | 1.05”OD | 1.05”OD | 1.5”D-GB | 1.05”OD | 1.05”OD | 1.5”D-GB |

| Water Capacity | 2m3/h | 4m3/h | 4m3/h | 10m3/h | 2m3/h | 4m3/h | 10m3/h |

| Working Pressure | 0.15-0.6MPa | ||||||

| Working Temperature | 5-50°C | ||||||

| Power Supply | No Need Power | AC100-240V/50-60Hz DC12V-1.5A | |||||

Another notable aspect of Fleck control valves is their user-friendly design. The valves feature a straightforward interface that allows users to easily program and adjust settings. This ease of use extends to the installation process as well. Fleck control valves are designed for easy installation, with clear instructions and minimal tools required. This makes them an accessible option for homeowners and business owners alike.

In terms of maintenance, Fleck control valves require minimal upkeep. Regular checks to ensure that the valve is functioning correctly and occasional cleaning are typically all that is needed to keep the valve in good working order. This low-maintenance design contributes to the overall cost-effectiveness of Fleck control valves, as it reduces the need for frequent service calls and replacement parts.

In conclusion, Fleck control valves are a key component of water treatment systems, providing reliable and efficient control of water flow. Their robust construction, user-friendly design, and low-maintenance requirements make them a practical choice for a wide range of applications. By understanding the functionality of these valves, users can ensure that they are operating their water treatment systems effectively and efficiently, maximizing the lifespan and performance of their Fleck control valves.

Maintenance Tips for Your Fleck Control Valves

Fleck control valves are renowned for their durability, efficiency, and ease of use in water treatment systems. However, like any mechanical device, they require regular maintenance to ensure optimal performance and longevity. This article provides a comprehensive guide on how to maintain your Fleck control valves effectively.

Firstly, it is essential to understand the function of your fleck control valve. These valves control the flow of water in your water treatment system, ensuring that the water is properly filtered and softened before it reaches your taps. Therefore, any malfunction in the valve can lead to inefficiencies in the water treatment process, potentially affecting the quality of your water.

In addition to cleaning, it’s also important to regularly inspect your fleck control valve for signs of wear and tear. Look for any visible damage, such as cracks or leaks, which could indicate a problem. If you notice any issues, it’s best to replace the valve as soon as possible to prevent further damage to your water treatment system.

Another key aspect of maintaining your fleck control valve is ensuring that it is properly lubricated. Lubrication reduces friction between the moving parts of the valve, helping it to operate more smoothly and reducing the risk of wear and tear. You should lubricate your valve at least once a year using a silicone-based lubricant, which is safe for use with water systems.

Furthermore, it’s crucial to monitor the performance of your fleck control valve regularly. If you notice any changes in the flow of water, such as a decrease in pressure or an increase in the amount of unfiltered water, this could indicate a problem with the valve. In such cases, it’s advisable to consult a professional for further inspection and repair.

Lastly, always remember to follow the manufacturer’s instructions when maintaining your fleck control valve. Different models may have specific maintenance requirements, so it’s important to refer to your user manual for detailed guidance.

In conclusion, regular maintenance of your fleck control valve is essential for ensuring the efficiency and longevity of your water treatment system. By cleaning, inspecting, lubricating, and monitoring your valve regularly, you can prevent potential problems and ensure that your water is always clean and safe to use. Remember, if you’re ever unsure about how to maintain your valve, it’s always best to consult a professional.