Exploring the Benefits of Maytag turbidity sensor in Dishwashers

In the world of household appliances, dishwashers have become an essential part of our daily lives. They save us time and effort by taking care of the dirty dishes, leaving us with more time to spend with our loved ones. One of the key features that make dishwashers efficient and effective is the turbidity sensor. Maytag, a well-known brand in the appliance industry, has incorporated this technology into their dishwashers to provide users with a superior cleaning experience.

The Maytag turbidity sensor is a cutting-edge technology that measures the cloudiness of the water in the dishwasher during the wash cycle. This sensor detects the level of soil and food particles in the water and adjusts the wash cycle accordingly to ensure that the dishes are cleaned thoroughly. By monitoring the turbidity of the water, the sensor can determine when the dishes are clean and when to stop the wash cycle, saving water and energy in the process.

One of the main benefits of the Maytag turbidity sensor is its ability to provide a more efficient and effective cleaning performance. Traditional dishwashers rely on a timer to determine the length of the wash cycle, which can result in overwashing or underwashing the dishes. With the turbidity sensor, the dishwasher can adapt to the level of dirtiness of the dishes, ensuring that they are cleaned properly without wasting water or energy.

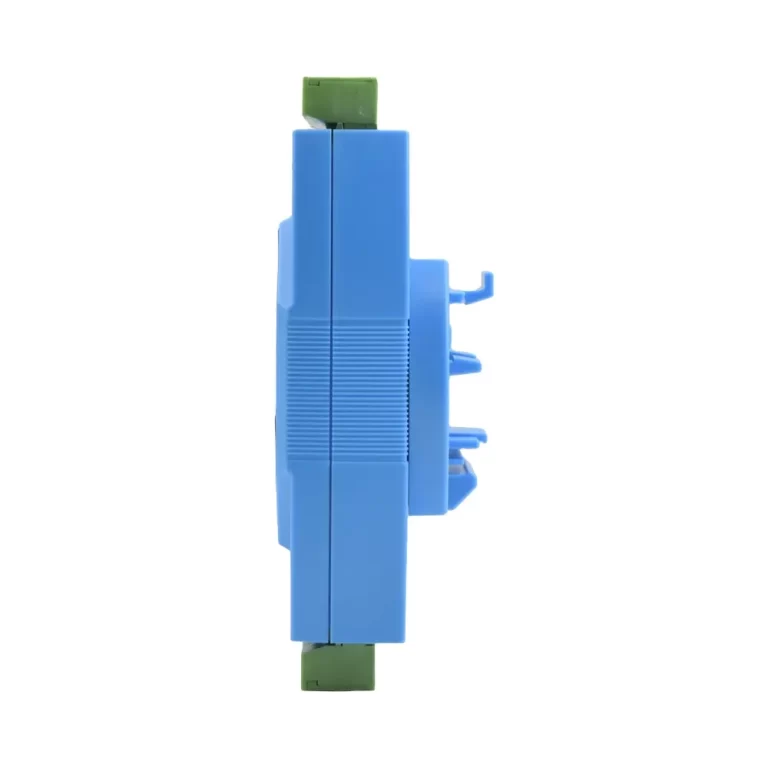

| Model | pH/ORP-8500A pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP:(-1999~+1999)mV; Temp.:(0.0~100.0)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | NTC10K Temperature compensation |

| Medium Temp. | (0~80)°C |

| Analog output | Double channels isolated; transportable(4~20)mA, instruments/ transmitter mode |

| Control Output | Triple channels semiconductor photoelectric switch, load current: AC/DC 30V, 50mA(max) |

| Communication port | RS485,Modbus RTU protocol |

| Working Environment | Temp.(0~80)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx94mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

Another advantage of the Maytag turbidity sensor is its ability to save time and effort for the user. By automatically adjusting the wash cycle based on the level of soil in the water, the sensor eliminates the need for pre-rinsing or scrubbing the dishes before loading them into the dishwasher. This not only saves time but also reduces water usage, making it a more environmentally friendly option.

Furthermore, the Maytag turbidity sensor helps to prolong the life of the dishwasher and its components. By ensuring that the dishes are cleaned properly in each wash cycle, the sensor reduces the risk of clogs and buildup in the dishwasher, which can lead to costly repairs and maintenance. This technology also helps to prevent damage to delicate dishes and glassware by adjusting the wash cycle to be gentler when needed.

In addition to its cleaning performance and efficiency, the Maytag turbidity sensor also contributes to energy savings. By stopping the wash cycle when the dishes are clean, the sensor prevents unnecessary water and energy consumption, resulting in lower utility bills for the user. This not only benefits the user financially but also reduces the environmental impact of using a dishwasher.

Overall, the Maytag turbidity sensor is a valuable feature that enhances the cleaning performance, efficiency, and longevity of dishwashers. By incorporating this technology into their appliances, Maytag has set a new standard for quality and innovation in the industry. Whether you are looking to upgrade your current dishwasher or purchase a new one, choosing a model with a turbidity sensor can provide you with a superior cleaning experience and peace of mind knowing that your dishes are being cleaned effectively and efficiently.

| CCT-5300 | |||||

| Constant | 10.00cm-1 | 1.000cm-1 | 0.100cm-1 | 0.010cm-1 | |

| Conductivity | (500~20,000) | (1.0~2,000) | (0.5~200) | (0.05~18.25) | |

| μS/cm | μS/cm | μS/cm | MΩ·cm | ||

| TDS | (250~10,000) | (0.5~1,000) | (0.25~100) | —— | |

| ppm | ppm | ppm | |||

| Medium Temp. | (0~50)℃(Temp. Compensation : NTC10K) | ||||

| Accuracy | Conductivity: 1.5%(FS) | ||||

| Resistivity: 2.0%(FS) | |||||

| TDS: 1.5%(FS) | |||||

| Temp.:±0.5℃ | |||||

| Temperature compensation | (0~50)℃ with 25℃ as Standard | ||||

| Analog Output | Single isolated(4~20)mA,instrument/transmitter for selection | ||||

| Control Output | SPDT relay, Load capacity : AC 230V/50A(Max) | ||||

| Power Supply | CCT-5300E : DC24V | CCT-5320E : AC 220V±15% | |||

| Working Environment | Temp. (0~50)℃;Relative Humidity ≤85%RH(none condensation) | ||||

| Storage Environment | Temp.(-20~60)℃; Relative Humidity ≤85%RH(none condensation) | ||||

| Dimension | 96mm×96mm×105mm (H×W×D) | ||||

| Hole Size | 91mm×91mm (H×W) | ||||

| Installation | Panel mounted, fast installation | ||||