Table of Contents

Benefits of Regular Maintenance for Brine Tank Valves

Brine tank valves are an essential component of water softening systems, as they control the flow of brine solution into the resin tank to regenerate the resin beads. Regular maintenance of these valves is crucial to ensure the proper functioning of the water softening system and to prevent costly repairs or replacements down the line.

One of the key benefits of regular maintenance for brine tank valves is the prevention of clogs and blockages. Over time, mineral deposits and debris can build up in the valve, causing it to become stuck or malfunction. By regularly cleaning and inspecting the valve, you can remove any buildup and ensure that it continues to operate smoothly.

Regular maintenance also helps to extend the lifespan of the brine tank valve. By keeping the valve clean and well-lubricated, you can prevent wear and tear that can lead to premature failure. This can save you money in the long run by avoiding the need for costly repairs or replacements.

In addition to preventing clogs and extending the lifespan of the valve, regular maintenance can also improve the efficiency of the water softening system. A clean and properly functioning valve will ensure that the right amount of brine solution is being delivered to the resin tank during regeneration, allowing the system to operate at peak performance. This can result in softer water, reduced energy consumption, and lower utility bills.

Another benefit of regular maintenance for brine tank valves is the prevention of leaks. A leaking valve can not only waste water and salt, but it can also cause damage to the surrounding area and lead to mold or mildew growth. By inspecting the valve regularly and replacing any worn or damaged parts, you can prevent leaks and keep your water softening system running smoothly.

Regular maintenance of brine tank valves is also important for ensuring the safety of your water supply. A malfunctioning valve can lead to over- or under-regeneration of the resin beads, resulting in water that is either too hard or too soft. This can affect the taste and quality of your water, as well as potentially harmful levels of minerals or contaminants. By maintaining the valve properly, you can ensure that your water softening system is operating as it should and providing you with clean, safe water.

In conclusion, regular maintenance of brine tank valves is essential for ensuring the proper functioning of water softening systems. By preventing clogs, extending the lifespan of the valve, improving efficiency, preventing leaks, and ensuring the safety of your water supply, regular maintenance can save you time and money in the long run. Make sure to schedule regular inspections and cleanings of your brine tank valve to keep your water softening system running smoothly for years to come.

Troubleshooting Common Issues with Brine Tank Valves

A brine tank valve is a crucial component of a water softening system, as it controls the flow of brine solution into the resin tank to regenerate the resin beads. However, like any mechanical part, brine tank valves can experience issues that may affect the performance of the water softener. In this article, we will discuss some common problems that may arise with brine tank valves and how to troubleshoot them.

One common issue with brine tank valves is leakage. If you notice water or brine solution leaking from the valve, it could be due to a faulty seal or gasket. To fix this problem, you will need to inspect the valve for any signs of wear or damage and replace the seal or gasket if necessary. It is important to use the correct replacement parts to ensure a proper seal and prevent further leakage.

Another common problem with brine tank valves is clogging. Over time, mineral buildup or debris can accumulate in the valve, causing it to become clogged and preventing the flow of brine solution. To address this issue, you can try cleaning the valve by soaking it in a solution of water and vinegar to dissolve any mineral deposits. If the clog is severe, you may need to disassemble the valve and manually remove the debris.

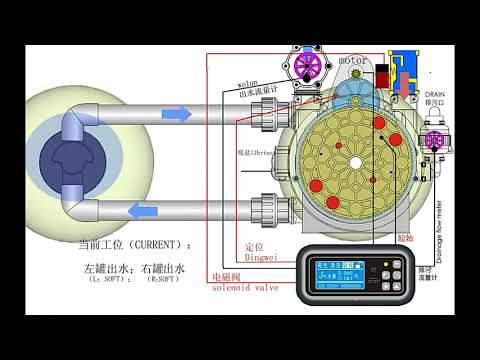

In some cases, a brine tank valve may fail to open or close properly. This could be due to a malfunctioning solenoid or control board. If the valve is not opening to allow brine solution to flow into the resin tank during regeneration, it may result in hard water coming out of the taps. On the other hand, if the valve fails to close after regeneration, it can lead to an overflow of brine solution in the tank. In either case, you will need to troubleshoot the electrical components of the valve to determine the cause of the malfunction and replace any faulty parts.

It is also important to check the brine tank itself for any issues that may be affecting the performance of the valve. If the tank is not properly maintained, it can lead to problems with the valve, such as salt bridging or mushing. Salt bridging occurs when a hard crust forms on top of the salt in the tank, preventing proper brine solution from being produced. Salt mushing, on the other hand, happens when the salt dissolves into a sludge-like substance at the bottom of the tank, which can clog the valve and impede its function. To prevent these issues, it is essential to regularly check and maintain the brine tank by breaking up any salt bridges and removing any mushy salt buildup.

In conclusion, brine tank valves play a vital role in the operation of water softening systems, and it is important to address any issues that may arise promptly. By troubleshooting common problems with brine tank valves, such as leakage, clogging, and malfunctioning, you can ensure that your water softener continues to function effectively and provide you with soft, clean water. Regular maintenance and inspection of both the valve and the brine tank are key to preventing problems and prolonging the life of your water softening system.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature\u00a0 |

| 3150 | 2.375″(2″) O.D. | 2″NPTF | 1″NPTM | 4″-8UN | 87W | 1\u2103-43\u2103 |