Table of Contents

Benefits of Using Hep2o Plastic Push-Fit Tank Connectors in Plumbing Applications

When it comes to plumbing applications, the choice of connectors plays a crucial role in ensuring the efficiency and reliability of the system. One popular option that has gained recognition for its quality and performance is the China Hep2o plastic push-fit tank connector, specifically the 15mm variant that comes with UL certification. This certification is a testament to the product’s compliance with safety and quality standards set by Underwriters Laboratories, a globally recognized safety certification company.

One of the key benefits of using Hep2o plastic push-fit tank connectors in plumbing applications is their ease of installation. These connectors are designed for quick and simple installation, eliminating the need for complex tools or specialized skills. The push-fit design allows for a secure and leak-free connection without the use of glues or solvents, making it a convenient choice for both professional plumbers and DIY enthusiasts.

In addition to ease of installation, Hep2o plastic push-fit tank connectors are known for their durability and reliability. Made from high-quality materials, these connectors are resistant to corrosion, ensuring long-term performance and minimal maintenance requirements. This durability is further enhanced by the UL certification, which guarantees that the product has undergone rigorous testing to meet safety and performance standards.

Another advantage of using Hep2o plastic push-fit tank connectors is their versatility. These connectors are suitable for a wide range of plumbing applications, including hot and cold water systems, central heating systems, and underfloor heating systems. Their compatibility with various pipe materials, such as copper, PEX, and PVC, makes them a versatile choice for different projects and installations.

Moreover, Hep2o plastic push-fit tank connectors are designed with efficiency in mind. Their innovative design allows for easy disconnection and reusability, making them a cost-effective solution for plumbing systems that may require modifications or repairs in the future. This flexibility not only saves time and effort during installation but also reduces the need for additional materials and components.

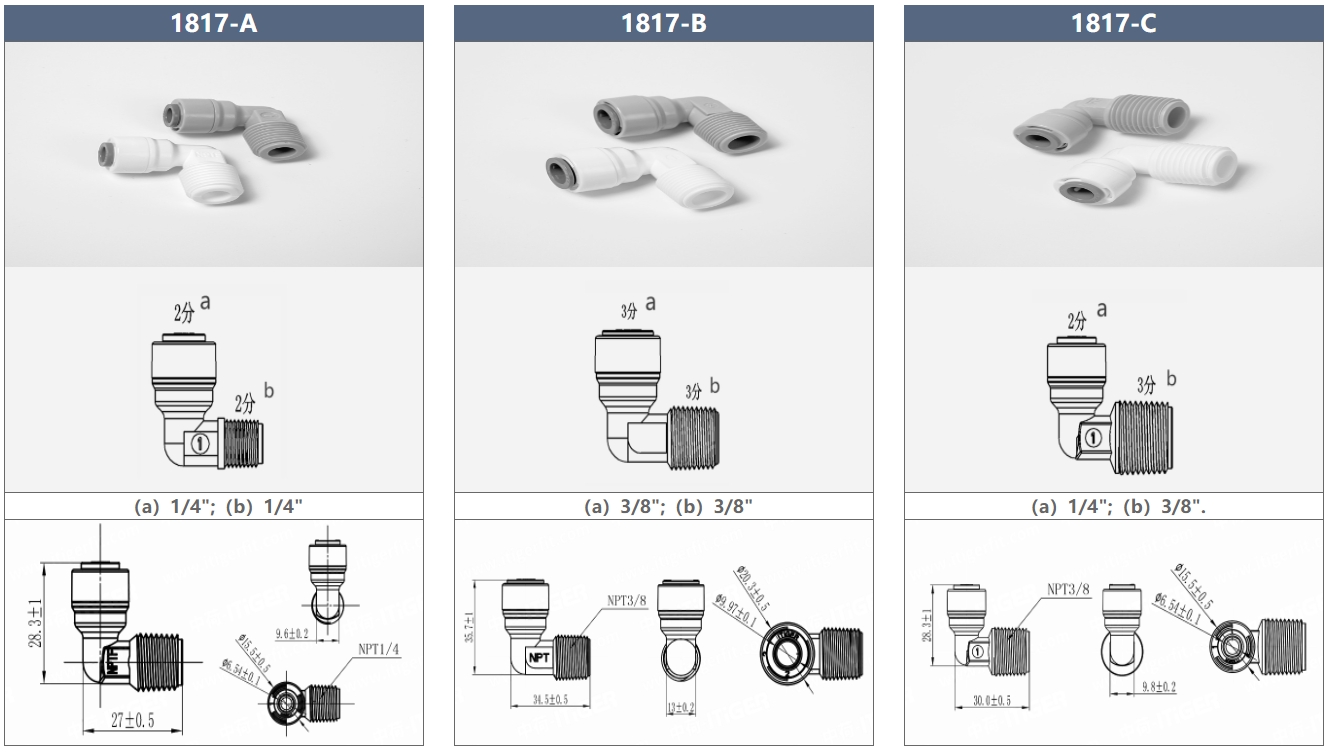

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/28 |

In conclusion, the China Hep2o plastic push-fit tank connector in the 15mm size with UL certification offers a range of benefits that make it a popular choice for plumbing applications. From easy installation and durability to versatility and efficiency, these connectors provide a reliable solution for various plumbing needs. Whether you are a professional plumber or a DIY enthusiast, Hep2o plastic push-fit tank connectors are a practical and reliable option to consider for your next plumbing project.

Step-by-Step Guide on Installing a 15mm Hep2o Plastic Push-Fit Tank Connector with UL Certification

A China Hep2o plastic push-fit tank connector in 15mm size with UL certification is a reliable and safe option for connecting pipes in various plumbing applications. Installing this connector is a straightforward process that can be completed with a few simple steps. In this guide, we will walk you through the step-by-step process of installing a 15mm Hep2o plastic push-fit tank connector with UL certification.

To begin the installation process, gather all the necessary tools and materials. You will need the Hep2o plastic push-fit tank connector, a pipe cutter or hacksaw, and a pipe deburrer. Make sure to work in a well-ventilated area with enough space to maneuver around the pipes.

The first step is to measure and cut the pipe to the desired length using a pipe cutter or hacksaw. Ensure that the cut is straight and clean to allow for a proper connection with the tank connector. Once the pipe is cut, use a pipe deburrer to remove any burrs or rough edges from the cut end of the pipe.

Next, insert the Hep2o plastic push-fit tank connector onto the pipe. Push the connector firmly onto the pipe until it reaches the stop. Make sure that the pipe is fully inserted into the connector to create a secure and leak-proof connection.

Once the connector is in place, check for any visible gaps or misalignments between the pipe and the connector. Ensure that the connection is tight and secure to prevent any leaks or water seepage.

After confirming that the connector is properly installed, test the connection by turning on the water supply. Check for any leaks or drips around the connection point. If you notice any leaks, turn off the water supply immediately and recheck the connection for proper installation.

If the connection is secure and leak-free, you can proceed to secure the pipe in place. Use pipe clips or brackets to support the pipe and prevent it from moving or shifting. Make sure to space the clips evenly along the length of the pipe for added stability.

Finally, label the newly installed pipe and connector for easy identification in the future. Use a permanent marker or labeling tape to mark the pipe with relevant information such as its purpose or destination.

In conclusion, installing a 15mm Hep2o plastic push-fit tank connector with UL certification is a simple process that can be completed with basic tools and materials. By following the steps outlined in this guide, you can ensure a secure and reliable connection for your plumbing system. Remember to always follow manufacturer instructions and guidelines for the best results.