The Benefits of Using High Grade Water Plastic Connectors for Tubing in China Factory Settings

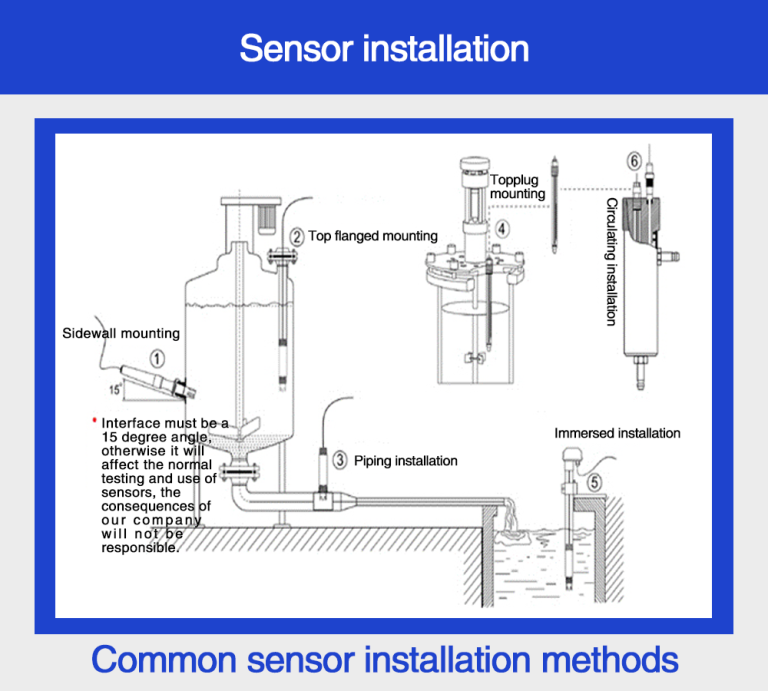

In the manufacturing industry, especially in China, the use of high-grade water plastic connectors for tubing is essential for ensuring efficient and reliable operations in factory settings. These connectors play a crucial role in connecting various components of a system, such as pipes, hoses, and tubing, to facilitate the flow of water and other fluids. By using high-quality connectors, factories can improve their production processes, reduce downtime, and enhance overall productivity.

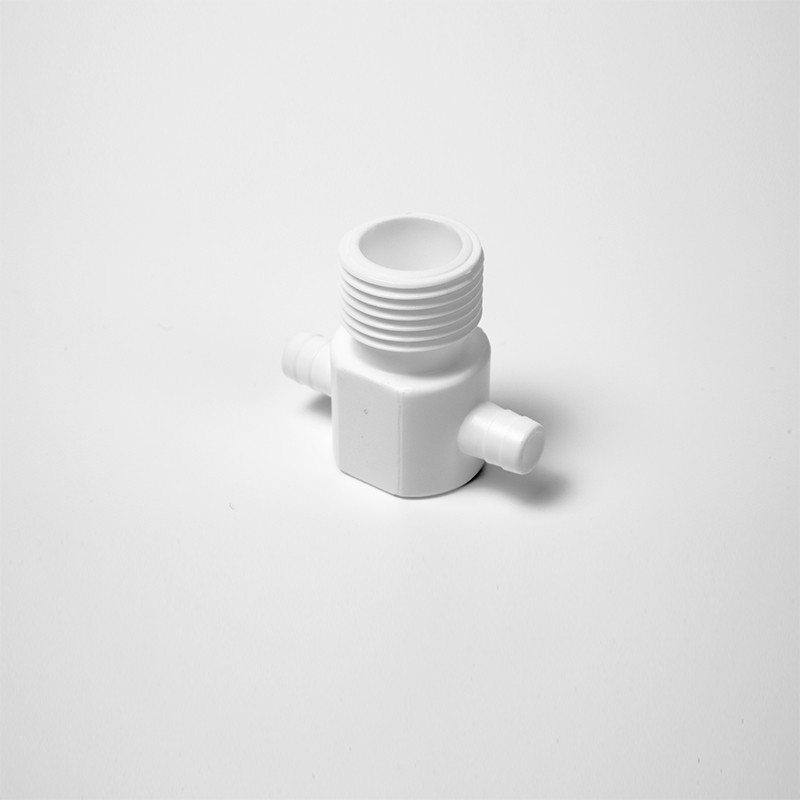

One of the key benefits of using high-grade water plastic connectors in China factory settings is their durability and reliability. These connectors are made from high-quality materials that are resistant to corrosion, chemicals, and extreme temperatures, making them ideal for use in harsh industrial environments. This durability ensures that the connectors can withstand the rigors of daily operations without breaking or leaking, which can lead to costly downtime and repairs.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/31 |

Additionally, high-grade water plastic connectors are designed to provide a secure and tight seal, preventing leaks and ensuring that fluids flow smoothly and efficiently through the system. This tight seal helps to maintain the integrity of the system and prevents contamination of the fluids being transported, which is crucial in industries such as food and beverage, pharmaceuticals, and electronics manufacturing.

Furthermore, high-grade water plastic connectors are easy to install and maintain, saving time and labor costs for factory operators. These connectors are designed for quick and simple assembly, allowing for fast and efficient installation without the need for specialized tools or equipment. Additionally, their low maintenance requirements mean that factory operators can focus on other tasks without having to worry about constantly monitoring and repairing the connectors.

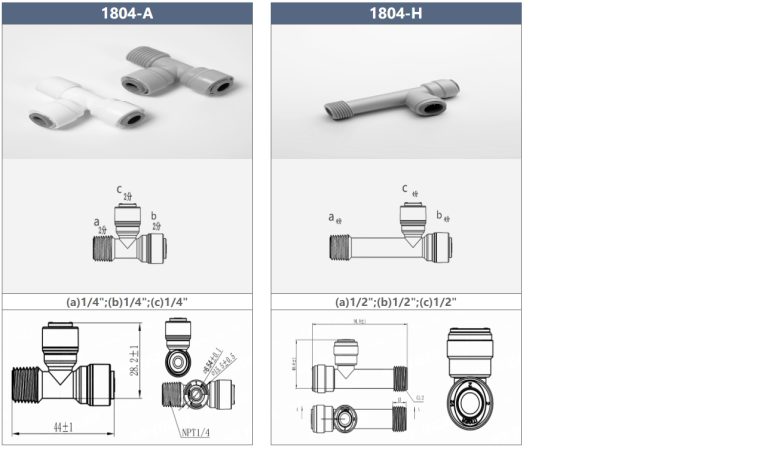

Another benefit of using high-grade water plastic connectors in China factory settings is their versatility and compatibility with a wide range of tubing sizes and materials. These connectors come in various shapes, sizes, and configurations to accommodate different types of tubing and piping systems, making them suitable for a wide range of applications. Whether it’s connecting PVC, polyethylene, or stainless steel tubing, high-grade water plastic connectors can provide a secure and reliable connection that meets the specific needs of the factory.

In addition to their durability, reliability, and versatility, high-grade water plastic connectors are also cost-effective solutions for factory operators in China. These connectors are typically more affordable than their metal counterparts, making them a cost-effective option for factories looking to reduce expenses without compromising on quality. Furthermore, their long lifespan and low maintenance requirements help to further reduce overall operating costs over time.

In conclusion, the benefits of using high-grade water plastic connectors for tubing in China factory settings are numerous and significant. From their durability and reliability to their ease of installation and maintenance, these connectors offer a cost-effective and efficient solution for connecting various components of a system. By investing in high-quality connectors, factory operators can improve their production processes, reduce downtime, and enhance overall productivity in their operations.