Table of Contents

Benefits of Using a clack backwash valve in Your Water Treatment System

A clack backwash valve is an essential component in water treatment systems, providing numerous benefits that contribute to the overall efficiency and effectiveness of the system. These valves are designed to control the flow of water during the backwashing process, ensuring that the filter media is properly cleaned and maintained. By incorporating a clack backwash valve into your water treatment system, you can experience improved water quality, reduced maintenance costs, and increased system longevity.

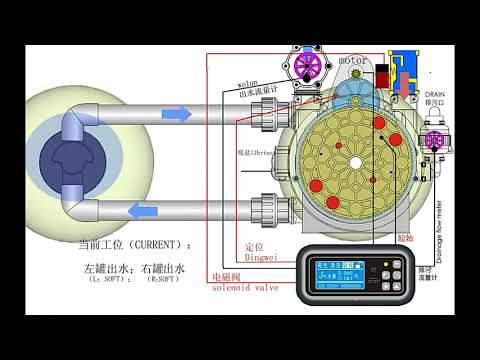

One of the primary benefits of using a clack backwash valve is its ability to effectively clean the filter media in water treatment systems. During the backwashing process, the valve reverses the flow of water through the filter, dislodging and removing any accumulated debris or contaminants. This helps to prevent clogging and maintain the efficiency of the filter, ensuring that your water treatment system continues to operate at peak performance.

In addition to improving the cleanliness of the filter media, a clack backwash valve also helps to enhance water quality. By removing impurities and contaminants from the filter, the valve ensures that the water passing through the system is clean and safe for consumption. This can lead to a noticeable improvement in the taste, odor, and clarity of the water, providing you with a higher quality drinking water supply.

Furthermore, using a clack backwash valve can help to reduce maintenance costs associated with water treatment systems. By regularly cleaning the filter media and preventing clogs, the valve helps to prolong the life of the system components and reduce the need for costly repairs or replacements. This can result in significant savings over time, making the investment in a clack backwash valve a cost-effective choice for water treatment system owners.

Another advantage of incorporating a clack backwash valve into your water treatment system is the increased system longevity that it provides. By maintaining the cleanliness and efficiency of the filter media, the valve helps to extend the lifespan of the entire system, ensuring that it continues to operate effectively for years to come. This can help to protect your investment in the water treatment system and provide you with peace of mind knowing that your water supply is being properly treated and maintained.

In conclusion, the benefits of using a clack backwash valve in your water treatment system are numerous and significant. From improving water quality and reducing maintenance costs to increasing system longevity, these valves play a crucial role in ensuring the efficiency and effectiveness of water treatment systems. By investing in a clack backwash valve, you can enjoy cleaner, safer water and a more reliable water treatment system for years to come.

How to Properly Maintain and Troubleshoot a clack backwash valve

A clack backwash valve is an essential component of a water treatment system, responsible for controlling the flow of water during the backwashing process. Proper maintenance and troubleshooting of the clack backwash valve are crucial to ensure the efficient operation of the water treatment system. In this article, we will discuss how to properly maintain and troubleshoot a clack backwash valve to prevent any issues that may arise.

Regular maintenance of the clack backwash valve is essential to ensure its proper functioning. One of the most important maintenance tasks is to regularly inspect the valve for any signs of wear or damage. Check for any leaks, cracks, or corrosion on the valve body, seals, and O-rings. If any damage is found, it is important to replace the damaged parts immediately to prevent further issues.

Another important maintenance task is to clean the clack backwash valve regularly to remove any dirt, debris, or mineral buildup that may affect its performance. Use a mild detergent and a soft brush to clean the valve thoroughly, paying special attention to the valve seat and sealing surfaces. Rinse the valve with clean water to remove any residue and ensure that it is completely clean before reinstalling it.

In addition to regular maintenance, it is also important to troubleshoot the clack backwash valve if any issues arise. One common issue that may occur is a leaking valve. If you notice water leaking from the valve body or connections, check for any loose fittings or damaged seals. Tighten any loose fittings and replace any damaged seals to stop the leak.

| SD manual softener | |||

| Model | SD2-R | SD4-R | SD10-R |

| Output Max | 4T/H | 7T/H | 15T/H |

Another common issue with Clack backwash valves is a stuck valve. If the valve is not opening or closing properly, it may be due to a buildup of dirt or debris inside the valve. In this case, disassemble the valve and clean it thoroughly to remove any obstructions that may be causing the valve to stick. Once the valve is clean, reassemble it and test its operation to ensure that it is functioning properly.

If the clack backwash valve is still not working properly after troubleshooting, it may be necessary to replace the valve with a new one. When replacing the valve, make sure to choose a compatible replacement that is designed for your specific water treatment system. Follow the manufacturer’s instructions for installation and calibration to ensure that the new valve is properly installed and functioning correctly.

In conclusion, proper maintenance and troubleshooting of a clack backwash valve are essential to ensure the efficient operation of a water treatment system. Regular inspection, cleaning, and replacement of damaged parts are key to preventing issues with the valve. If any issues arise, troubleshoot the valve to identify and resolve the problem. If necessary, replace the valve with a new one to ensure that the water treatment system continues to operate effectively. By following these maintenance and troubleshooting tips, you can keep your clack backwash valve in top condition and ensure the quality of your water treatment system.