How to Properly Maintain Your clack valve water softener: A Comprehensive Guide

Water softeners are essential appliances in many households, helping to remove minerals such as calcium and magnesium from hard water. One popular brand of water softener is the clack valve water softener, known for its durability and efficiency. To ensure that your clack valve water softener continues to function properly, it is important to perform regular maintenance. In this comprehensive guide, we will walk you through the steps to properly maintain your clack valve water softener.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| AF2 | automatic filter valve | 2 | O | O | O | O |

First and foremost, it is crucial to refer to the manufacturer’s manual for specific instructions on how to maintain your clack valve water softener. The manual will provide detailed information on how to clean and maintain the various components of the water softener. It is important to follow these instructions carefully to avoid damaging the appliance.

One of the most important maintenance tasks for your clack valve water softener is to regularly check and replace the resin beads. These beads are responsible for removing minerals from the water, and over time, they can become saturated and less effective. To check the resin beads, you will need to open the resin tank and inspect the beads for signs of wear or damage. If the beads appear worn out, it is time to replace them.

In addition to checking and replacing the resin beads, it is also important to clean the brine tank of your clack valve water softener. The brine tank is where the salt used to regenerate the resin beads is stored. Over time, salt residue and other debris can build up in the tank, affecting the performance of the water softener. To clean the brine tank, you will need to empty it completely and scrub the interior with a mixture of water and mild detergent. Be sure to rinse the tank thoroughly before refilling it with salt.

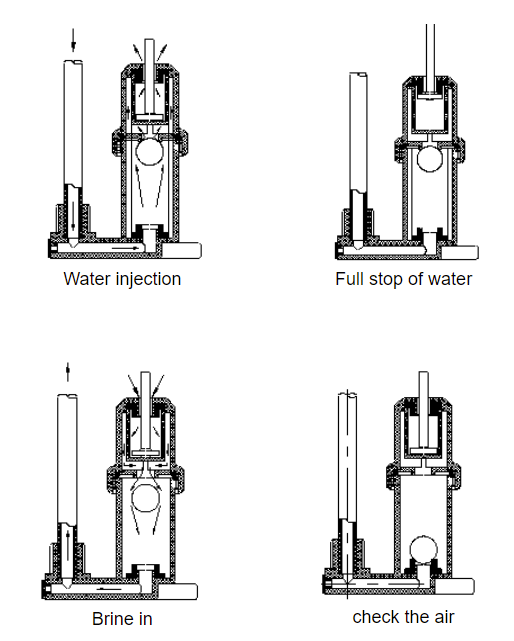

Another important maintenance task for your clack valve water softener is to regularly check and clean the control valve. The control valve is responsible for regulating the flow of water through the water softener, and if it becomes clogged or damaged, it can affect the performance of the appliance. To clean the control valve, you will need to disconnect it from the water softener and remove any debris or buildup that may be present. Be sure to reassemble the control valve properly before reconnecting it to the water softener.

In addition to these maintenance tasks, it is also important to regularly check the salt levels in your clack valve water softener. The salt is essential for regenerating the resin beads and ensuring that the water softener functions properly. If the salt levels are low, the water softener may not be able to effectively remove minerals from the water. Be sure to check the salt levels regularly and refill the brine tank as needed.

In conclusion, proper maintenance is essential for ensuring that your clack valve water softener continues to function efficiently. By following the manufacturer’s instructions and performing regular maintenance tasks such as checking and replacing the resin beads, cleaning the brine tank, and inspecting the control valve, you can extend the life of your water softener and enjoy clean, soft water in your home. Remember to refer to the manufacturer’s manual for specific instructions on how to maintain your clack valve water softener, and don’t hesitate to contact a professional if you encounter any issues.