Table of Contents

Benefits of Using Conductivity Probe Equipment in Water Quality Monitoring

Conductivity probe equipment plays a crucial role in water quality monitoring, providing valuable data that helps ensure the safety and health of our water sources. These probes are designed to measure the electrical conductivity of water, which is a key indicator of its purity and overall quality. By using conductivity probe equipment, researchers and environmental professionals can quickly and accurately assess the levels of dissolved ions and contaminants in a water sample.

One of the primary benefits of using conductivity probe equipment is its ability to provide real-time data on water quality. Unlike traditional methods that require samples to be sent to a lab for analysis, conductivity probes can deliver instant results in the field. This allows for faster decision-making and response to potential water quality issues, ultimately helping to protect public health and the environment.

Additionally, conductivity probe equipment is highly sensitive and can detect even small changes in water quality. This level of precision is essential for monitoring water sources that are susceptible to contamination, such as rivers, lakes, and groundwater. By using conductivity probes, researchers can identify trends and patterns in water quality over time, helping to pinpoint sources of pollution and develop effective mitigation strategies.

| FL-9900 High Precision Type Runner Flow Controller | ||

| Measuring range | Frequency | 0~2K Hz |

| Velocity of flow | 0.5~5 m/s | |

| Instantaneous flow | 0~2000 m³/h | |

| Cumulative flow | 0~9999 9999.999 m³ | |

| Applicable pipe diameter range | DN15~DN100;DN125~DN300 | |

| Resolution | 0.01 m³/h | |

| Refresh rate | 1s | |

| Accuracy class | Level 2.0 | |

| Repeatability | ±0.5% | |

| Sensor input | Radius:0~2K Hz | |

| Supply voltage:DC 24V(instrument internal supply) | ||

| The electronic unit automatically temperature compensates for errors | +0.5%FS; | |

| 4-20mA | Technical characteristics | Meter/transmitter dual mode (photoelectric isolation) |

| Loop resistance | 500Q(max),DC24V; | |

| Transmission accuracy | ±0.01mA | |

| Control port | Contact mode | Passive relay control output |

| Load capacity | Load current 5A (max) | |

| Function selection | Instantaneous flow upper/lower alarm | |

| Mains supply | Working voltage: DC24V 4V Power consumption :<; 3.OW | |

| Cable length | Factory configuration: 5m, can be agreed: (1~500) m | |

| Environmental requirement | Temperature: 0~50℃; Relative humidity: ≤85%RH | |

| Storage environment | Temperature: (-20~60) ℃; Humidity: 85%RH | |

| Overall dimension | 96×96×72mm(height × width × depth) | |

| Opening size | 92×92mm | |

| Installation mode | Disc mounted, fast fixed | |

| Sensor | Body material | Body: Engineering plastic PP; Bearing :Zr02 high temperature zirconia |

| Flow rate range | 0.5~5 m/s | |

| Withstand pressure | ≤0.6MPa | |

| Supply voltage | lDC 24V | |

| Output pulse amplitude| | Vp≥8V | |

| Normal pipe diameter | DN15~DN100;DN125~DN600 | |

| Medium characteristic | Single-phase medium(0~60℃) | |

| Installation mode | Direct line insertion | |

Furthermore, conductivity probe equipment is versatile and can be used in a wide range of applications. Whether monitoring drinking water supplies, assessing the impact of industrial activities on water quality, or studying the effects of climate change on aquatic ecosystems, conductivity probes provide valuable insights that inform decision-making and policy development.

Another key benefit of using conductivity probe equipment is its cost-effectiveness. Traditional water quality monitoring methods can be time-consuming and expensive, requiring specialized equipment and trained personnel. In contrast, conductivity probes are relatively affordable and easy to use, making them accessible to a wide range of organizations and individuals involved in water quality monitoring.

Moreover, conductivity probe equipment is portable and lightweight, making it ideal for fieldwork and remote monitoring. Researchers can easily transport conductivity probes to different locations and collect data in real-time, without the need for complex infrastructure or laboratory facilities. This flexibility allows for more comprehensive and efficient monitoring of water quality across diverse environments and conditions.

In conclusion, conductivity probe equipment offers numerous benefits for water quality monitoring, including real-time data collection, high sensitivity, versatility, cost-effectiveness, and portability. By using conductivity probes, researchers and environmental professionals can gain valuable insights into the health and safety of our water sources, helping to protect ecosystems and public health. As the importance of water quality monitoring continues to grow, conductivity probe equipment will play an increasingly vital role in safeguarding our most precious resource.

How to Properly Calibrate and Maintain Conductivity Probe Equipment

Conductivity probe equipment is an essential tool in various industries, including water treatment, food and beverage production, and pharmaceutical manufacturing. These probes measure the ability of a solution to conduct electricity, which is directly related to the concentration of ions present in the solution. Proper calibration and maintenance of conductivity probe equipment are crucial to ensure accurate and reliable measurements.

To begin with, calibration is the process of adjusting the probe to ensure that it provides accurate readings. Calibration should be done regularly, as the probe’s accuracy can drift over time due to factors such as temperature changes, exposure to contaminants, or general wear and tear. Most conductivity probes can be calibrated using a standard solution with a known conductivity value. It is important to follow the manufacturer’s instructions for calibration, as the procedure may vary depending on the type of probe.

When calibrating a conductivity probe, it is essential to use high-quality calibration solutions and to properly clean the probe before and after calibration. Cleaning the probe with a mild detergent and rinsing it with deionized water can help remove any contaminants that may affect the accuracy of the readings. Additionally, it is important to ensure that the calibration solutions are at the correct temperature, as temperature can significantly impact conductivity measurements.

After calibrating the probe, it is important to regularly check its performance by measuring a known standard solution. This can help identify any drift in the probe’s accuracy and allow for adjustments to be made as needed. If the probe consistently provides inaccurate readings, it may be time to replace the probe or have it professionally serviced.

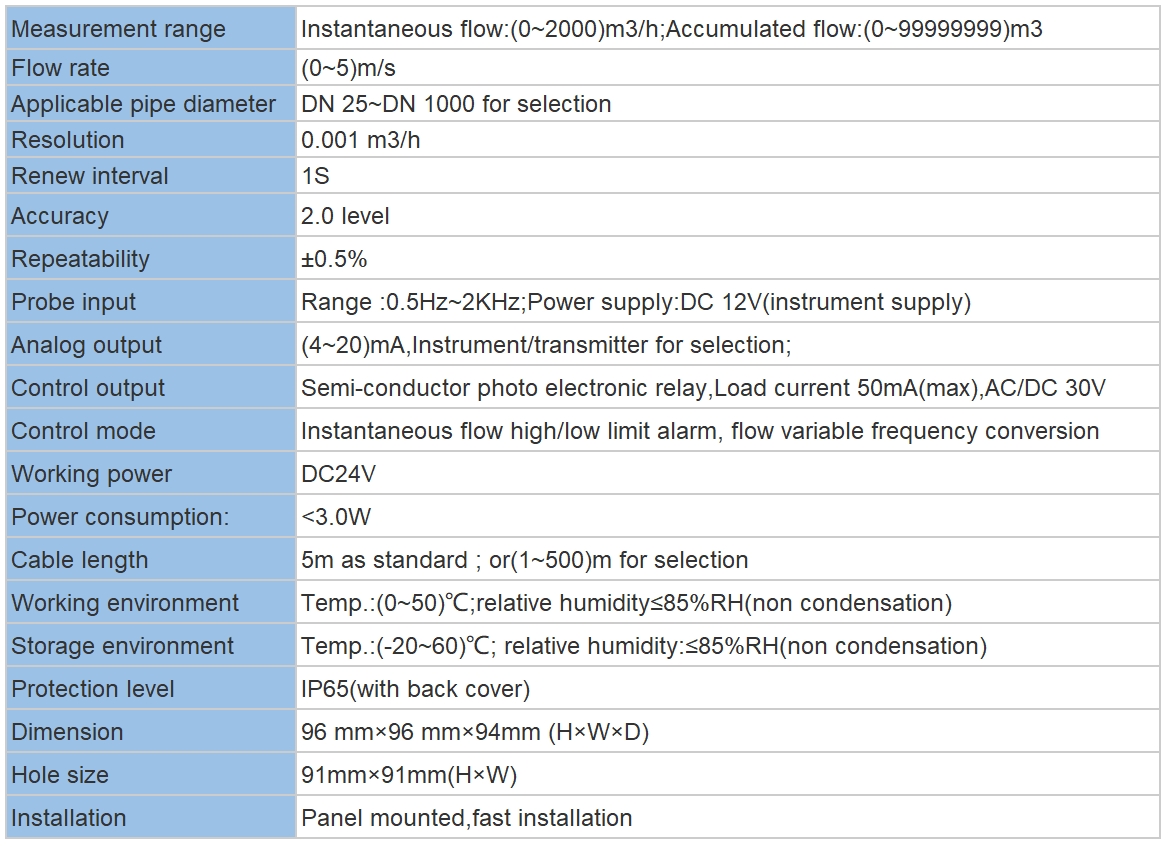

| Instrument model | FET-8920 | |

| Measurement range | Instantaneous flow | (0~2000)m3/h |

| Accumulative flow | (0~99999999)m3 | |

| Flow rate | (0.5~5)m/s | |

| Resolution | 0.001m3/h | |

| Accuracy level | Less than 2.5% RS or 0.025m/s.whichever is the largest | |

| Conductivity | >20μS/cm | |

| (4~20)mA output | Number of channels | Single channel |

| Technical features | Isolated,reversible,adjustable, meter/transmission dual mode | |

| Loop resistance | 400Ω(Max), DC 24V | |

| Transmission accuracy | ±0.1mA | |

| Control output | Number of channels | Single channel |

| Electrical contact | Semiconductor photoelectric relay | |

| Load capacity | 50mA(Max), DC 30V | |

| Control mode | Instantaneous amount upper/lower limit alarm | |

| Digital output | RS485(MODBUS protocol ),Impulse output1KHz | |

| Working power | Power supply | DC 9~28V |

| source | Power Consumption | ≤3.0W |

| Diameter | DN40~DN300(can be customized) | |

| Working environment | Temperature:(0~50) ℃; Relative humidity: ≤85%RH(none condensation) | |

| Storage environment | Temperature:(-20~60) ℃; Relative humidity: ≤85%RH(none condensation) | |

| Protection grade | IP65 | |

| Installation method | Insertion pipeline installation | |

In addition to calibration, proper maintenance of conductivity probe equipment is essential to ensure its longevity and accuracy. Regularly cleaning the probe with a mild detergent and rinsing it with deionized water can help prevent the buildup of contaminants that may interfere with conductivity measurements. It is also important to store the probe properly when not in use, as exposure to harsh chemicals or extreme temperatures can damage the probe.

Furthermore, it is important to regularly inspect the probe for any signs of damage or wear. Cracks or scratches on the probe’s surface can affect its ability to accurately measure conductivity. If any damage is found, the probe should be replaced or repaired by a qualified technician.

In conclusion, proper calibration and maintenance of conductivity probe equipment are essential to ensure accurate and reliable measurements. Regular calibration using high-quality calibration solutions, proper cleaning, and storage, as well as regular inspection of the probe, can help prolong the life of the equipment and ensure accurate readings. By following these guidelines, industries can rely on their conductivity probe equipment to provide accurate measurements for their processes.