Table of Contents

Benefits of Using JUMO Conductivity Sensors in Industrial Applications

Conductivity sensors are essential tools in industrial applications where monitoring and controlling the conductivity of liquids is crucial. JUMO, a leading manufacturer of sensors and automation solutions, offers a range of high-quality conductivity sensors that are designed to meet the demanding requirements of various industries. In this article, we will explore the benefits of using JUMO conductivity sensors in industrial applications.

One of the key advantages of JUMO conductivity sensors is their accuracy and reliability. These sensors are built to deliver precise and consistent measurements, ensuring that the conductivity levels of liquids are monitored with high precision. This level of accuracy is essential in industries where even small deviations in conductivity can have a significant impact on the quality of the final product.

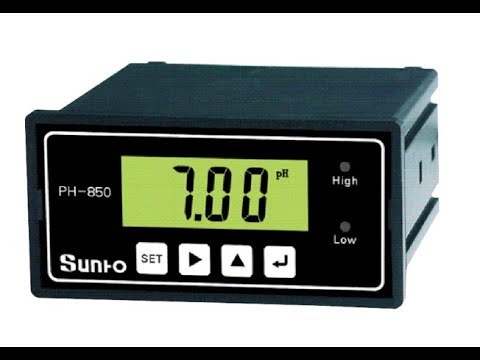

| Model | pH/ORP-8851/9900 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~60℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | Big Screen LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | DC24V/0.5A or AC85-265V±10% 50/60Hz |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×72mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In addition to accuracy, JUMO conductivity sensors are also known for their durability and longevity. These sensors are built to withstand harsh industrial environments, including exposure to chemicals, high temperatures, and pressure. This robust construction ensures that the sensors can continue to perform reliably even in the most challenging conditions, reducing the need for frequent maintenance and replacement.

Another benefit of using JUMO conductivity sensors is their versatility. These sensors are available in a range of configurations to suit different applications, from simple point sensors to sophisticated online monitoring systems. This flexibility allows industries to choose the right sensor for their specific needs, whether they require continuous monitoring of conductivity or periodic spot checks.

Furthermore, JUMO conductivity sensors are easy to install and integrate into existing industrial processes. These sensors are designed for simple and straightforward installation, with options for both in-line and immersion mounting. Additionally, JUMO offers a range of accessories and support services to help industries seamlessly integrate the sensors into their operations, minimizing downtime and disruption.

One of the key features of JUMO conductivity sensors is their low maintenance requirements. These sensors are designed to be self-cleaning, reducing the buildup of deposits and ensuring consistent performance over time. This not only saves time and effort on maintenance but also helps to prolong the lifespan of the sensors, providing long-term cost savings for industries.

Moreover, JUMO conductivity sensors are equipped with advanced features such as temperature compensation and automatic calibration, further enhancing their accuracy and reliability. These features help to ensure that the sensors deliver precise measurements even in fluctuating conditions, providing industries with confidence in the data they receive.

In conclusion, JUMO conductivity sensors offer a range of benefits for industrial applications, including accuracy, reliability, durability, versatility, ease of installation, low maintenance requirements, and advanced features. These sensors are designed to meet the demanding requirements of various industries, providing precise and consistent measurements of conductivity in liquids. By choosing JUMO conductivity sensors, industries can improve the quality of their products, optimize their processes, and reduce costs in the long run.

How to Calibrate and Maintain JUMO Conductivity Sensors for Accurate Readings

Conductivity sensors are essential tools in various industries for measuring the electrical conductivity of a solution. JUMO is a well-known manufacturer of high-quality conductivity sensors that are used in a wide range of applications, from water treatment to chemical processing. To ensure accurate readings, it is important to calibrate and maintain JUMO conductivity sensors regularly.

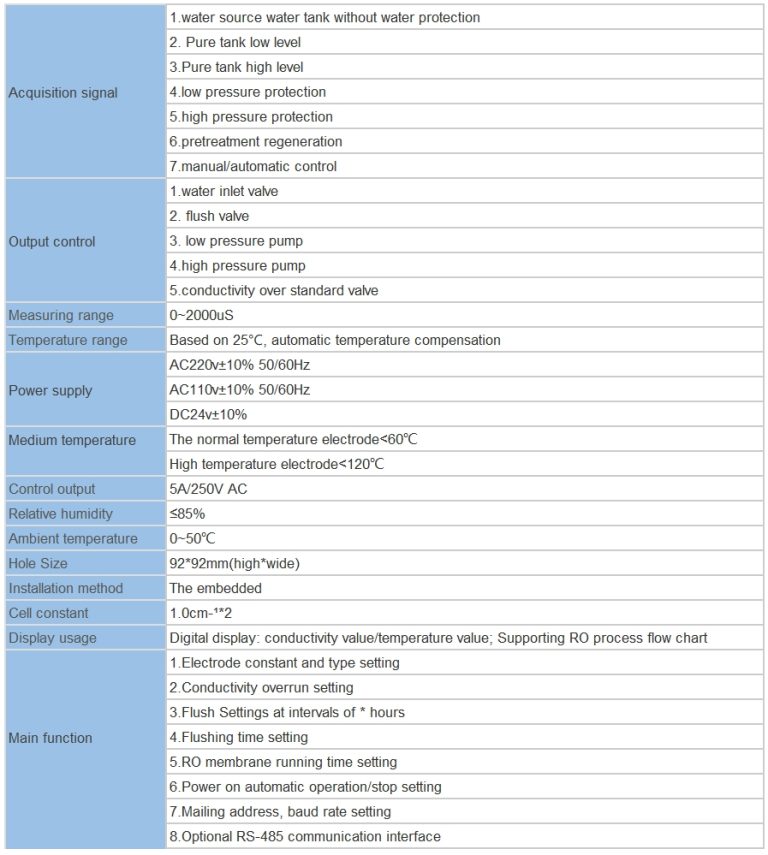

| Model | CCT-8301A Conductivity/Resistivity/TDS/TEMP Online Controller |

| Constant | 0.01cm-1, 0.1 cm-1, 1.0cm-1, 10.0 cm-1 |

| Conductivity | (500~100,000)uS/cm,(1~10,000)uS/cm, (0.5~200)uS/cm, (0.05~18.25) MΩ·cm |

| TDS | (250~50,000)ppm, (0.5~5,000)ppm, (0.25~100)ppm |

| Medium Temp. | (0~180)°C(Temp.Compensation: Pt1000) |

| Resolution | Conductivity: 0.01uS/cm, 0.01mS/cm; Resistivity: 0.01MΩ·cm; TDS:0.01ppm, Temp.: 0.1℃ |

| Accuracy | Conductivity: 1.5%(FS), Resistivity:2.0%(FS), TDS: 1.5%(FS), Temp.: +/-0.5℃ |

| Temp. compensation | With25°C as standard under normal medium; With 90C as standard under high temp medium |

| Communication port | RS485 Modbus RTU protocol |

| Analog output | Double channel (4~20)mA. Instrument/Transmitter for selection |

| Control Output | Triple channels photo-electronic semiconductor relay switch, Load capacity: AC/DC 30V,50mA(max) |

| Working Environment | Temp.(0~50)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC24V+/-15% |

| Protection Level | IP65 (with the back cover) |

| Dimension | 96mmx96mmx94mm(HxWxD) |

| Hole Size | 9lmmx91mm(HxW) |

Calibrating a JUMO conductivity sensor is a straightforward process that involves comparing the sensor’s readings to a known standard solution. This can be done using a calibration solution with a known conductivity value. It is recommended to calibrate the sensor before each use to ensure accurate measurements. To calibrate the sensor, simply immerse it in the calibration solution and adjust the sensor’s settings until the readings match the known conductivity value.

In addition to regular calibration, it is important to properly maintain JUMO conductivity sensors to ensure their longevity and accuracy. One of the most important maintenance tasks is cleaning the sensor regularly to remove any buildup or contaminants that may affect its performance. This can be done by gently wiping the sensor with a soft cloth or using a cleaning solution recommended by the manufacturer.

Another important aspect of maintaining JUMO conductivity sensors is storing them properly when not in use. It is important to store the sensors in a clean, dry environment to prevent any damage or contamination. Additionally, it is recommended to store the sensors in a protective case to prevent any physical damage.

Regularly inspecting the sensor for any signs of wear or damage is also important for maintaining its accuracy. If any damage is found, it is important to replace the sensor immediately to prevent any inaccuracies in the readings. It is also recommended to regularly check the sensor’s cables and connections to ensure they are secure and in good condition.

In conclusion, calibrating and maintaining JUMO conductivity sensors is essential for ensuring accurate readings in various industrial applications. By following the recommended calibration procedures and properly maintaining the sensors, users can ensure that their measurements are reliable and consistent. Regular calibration, cleaning, storage, and inspection are key aspects of maintaining JUMO conductivity sensors for optimal performance. By taking these steps, users can rely on their JUMO conductivity sensors to provide accurate and reliable measurements for years to come.