Understanding the Key Components of an electrical conductivity meter

Electrical conductivity meters are essential tools used in various industries to measure the ability of a substance to conduct electricity. These meters are commonly used in water treatment plants, laboratories, and agricultural settings to monitor the quality of water, soil, and other solutions. Understanding the key components of an electrical conductivity meter is crucial for ensuring accurate and reliable measurements.

One of the most important components of an electrical conductivity meter is the probe. The probe is the part of the meter that comes into direct contact with the substance being tested. It is typically made of a material that is a good conductor of electricity, such as stainless steel or graphite. The probe contains electrodes that transmit an electrical current through the substance, allowing the meter to measure its conductivity.

Another key component of an electrical conductivity meter is the circuitry. The circuitry is responsible for generating and measuring the electrical current that passes through the substance. It consists of a power source, such as a battery or AC adapter, as well as electronic components that control the flow of electricity and convert the measured data into a readable format. The circuitry is crucial for ensuring accurate and precise measurements.

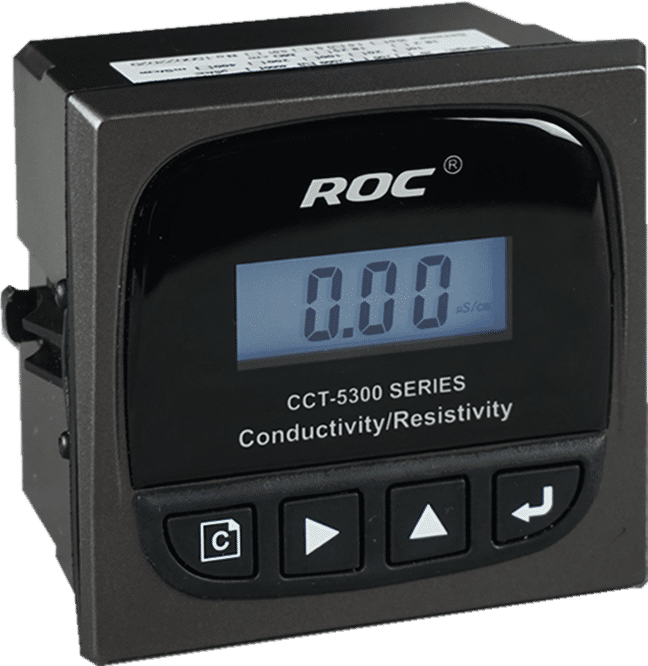

The display is another important component of an electrical conductivity meter. The display is where the measured data is shown to the user. It can be a simple analog display with a needle that moves to indicate conductivity levels, or a digital display that shows numerical values. The display is essential for allowing the user to easily read and interpret the measurements taken by the meter.

| Model | pH/ORP-810 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | \u00b10.1pH; \u00b12mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0\uff5e50\u2103; High temp 0\uff5e100\u2103 |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V\u00b110% 50/60Hz or AC 110V\u00b110% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0\uff5e50\u2103 |

| Relative humidity\u226485% | |

| Dimensions | 96\u00d796\u00d7100mm(H\u00d7W\u00d7L) |

| Hole Size | 92\u00d792mm(H\u00d7W) |

| Installation Mode | Embedded |

In addition to the probe, circuitry, and display, many electrical conductivity meters also include additional features such as temperature compensation and automatic calibration. Temperature compensation is important for ensuring accurate measurements, as the conductivity of a substance can vary with changes in temperature. Automatic calibration allows the meter to be calibrated quickly and easily, ensuring that it is always accurate and reliable.

Overall, understanding the key components of an electrical conductivity meter is essential for ensuring accurate and reliable measurements. The probe, circuitry, display, and additional features all play a crucial role in the functionality of the meter. By familiarizing yourself with these components, you can ensure that your electrical conductivity meter is properly maintained and calibrated, allowing you to obtain accurate and reliable measurements in your work.