“Conducting power through resistance.”

Understanding the Concept of Electrical Resistivity in Metals

Electrical resistivity is a fundamental property of metals that plays a crucial role in determining their conductivity. In simple terms, electrical resistivity is a measure of how strongly a material opposes the flow of electric current. Metals are known for their high conductivity, but they still exhibit some level of resistance to the flow of electricity due to their atomic structure.

The concept of electrical resistivity can be understood by considering the behavior of electrons in a metal. In a metal, electrons are free to move around within the atomic lattice, carrying electric charge. However, they still encounter obstacles in the form of lattice vibrations and impurities that hinder their movement. These obstacles create a resistance to the flow of current, which is quantified by the electrical resistivity of the metal.

The electrical resistivity of a metal is typically measured in units of ohm-meters (Ωm). It is influenced by various factors, including the temperature of the metal, its purity, and its crystal structure. In general, metals with a higher electrical resistivity will have lower conductivity, as they offer more resistance to the flow of current.

| Product Model | MFC-8800 | |

| Communication port | The uplink slave channel Modbus RTU protocol RS485 port is connected with DTU and DCS | |

| Downlink master channel RS485 port of Modbus RTU protocol is connected with data acquisition terminal | ||

| 4~20mA output | 1 channel two-wire type Maximum loop resistance 400Ω | |

| 4~20mA Input | 2 channel channel two-wire type( initiative feed) | |

| DI Input | 2channels Photoelectric isolation logic switch | |

| DO Output | 3 channels relay | 1 SPDT AC220V; 3A(MAX) |

| (only for drive signal) | 2 SPST AC220V; 3A(MAX) | |

| 1channel Photoelectric switch | Proportional pulse/frequency | |

| Load capacity:100mA/DC30V | ||

| Data acquisition | Data acquisition collection,with 3 channels DC24V sensor power supply | |

| Display mode | 3.5”(or 4”)colorful LCD touch screen | |

| Power supply | Wide power range :(12-24)V | |

| Consumption | <5W | |

| Environment requirements | Environment temp:(5~45)℃; relative humidity:≤90%。 | |

| Hole dimension | (91×91)mm hole dimension;panel dimension(100*100)mm | |

One of the key factors that affect the electrical resistivity of a metal is its temperature. As the temperature of a metal increases, the lattice vibrations become more pronounced, leading to an increase in resistance. This phenomenon is known as the temperature coefficient of resistivity, which describes how the resistivity of a material changes with temperature. In most metals, the resistivity increases with temperature, although there are exceptions such as superconductors that exhibit zero resistivity at low temperatures.

The purity of a metal also plays a significant role in determining its electrical resistivity. Impurities in the form of foreign atoms or defects in the crystal lattice can disrupt the movement of electrons, increasing the resistance of the material. This is why high-purity metals are often preferred for applications where low resistivity is essential, such as in electrical wiring or electronic components.

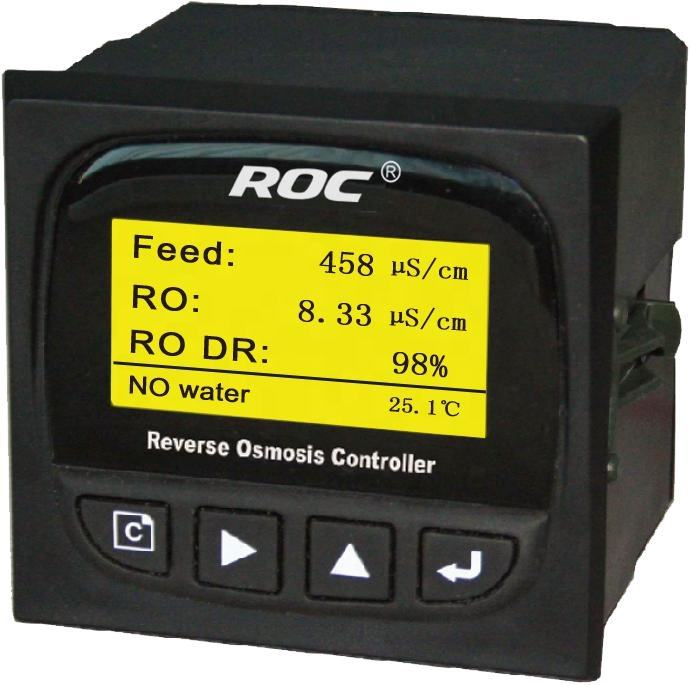

| ROS-2210 Double-Stage Reverse Osmosis Program Controller | |

| 1.water source water tank without water protection | |

| 2. Pure tank low level | |

| 3.Pure tank high level | |

| Acquisition signal | 4.low pressure protection |

| 5.high pressure protection | |

| 6.pretreatment regeneration | |

| 7.manual/automatic control | |

| 1.water inlet valve | |

| 2. flush valve | |

| Output control | 3. low pressure pump |

| 4.high pressure pump | |

| 5.conductivity over standard valve | |

| Measuring range | 0~2000uS |

| Temperature range | Based on 25℃, automatic temperature compensation |

| AC220v±10% 50/60Hz | |

| Power supply | AC110v±10% 50/60Hz |

| DC24v±10% | |

| Medium temperature | The normal temperature electrode<60℃ |

| High temperature electrode<120℃ | |

| Control output | 5A/250V AC |

| Relative humidity | ≤85% |

| Ambient temperature | 0~50℃ |

| Hole Size | 92*92mm(high*wide) |

| Installation method | The embedded |

| Cell constant | 1.0cm-¹*2 |

| Display usage | Digital display: conductivity value/temperature value; Supporting RO process flow chart |

| 1.Electrode constant and type setting | |

| 2.Conductivity overrun setting | |

| 3.Flush Settings at intervals of * hours | |

| Main function | 4.Flushing time setting |

| 5.RO membrane running time setting | |

| 6.Power on automatic operation/stop setting | |

| 7.Mailing address, baud rate setting | |

| 8.Optional RS-485 communication interface | |

The crystal structure of a metal can also influence its electrical resistivity. Metals with a regular, ordered crystal lattice tend to have lower resistivity compared to those with a more disordered structure. This is because a well-organized lattice allows electrons to move more freely, reducing the overall resistance to current flow.