Table of Contents

Understanding the Functionality of Electronic Air Valve Control

Electronic air valve control is a critical component in various industrial and automotive applications. It is a system that regulates the flow of air or gas in an engine or other mechanical systems. This article aims to provide a comprehensive understanding of the functionality of electronic air valve control.

Electronic air valve control systems are designed to manage the volume of air that enters an engine’s combustion chamber. This control is crucial as it directly influences the engine’s performance, fuel efficiency, and emission levels. The system operates based on the principle of electromechanical actuation, where an electric current is used to drive a mechanical process.

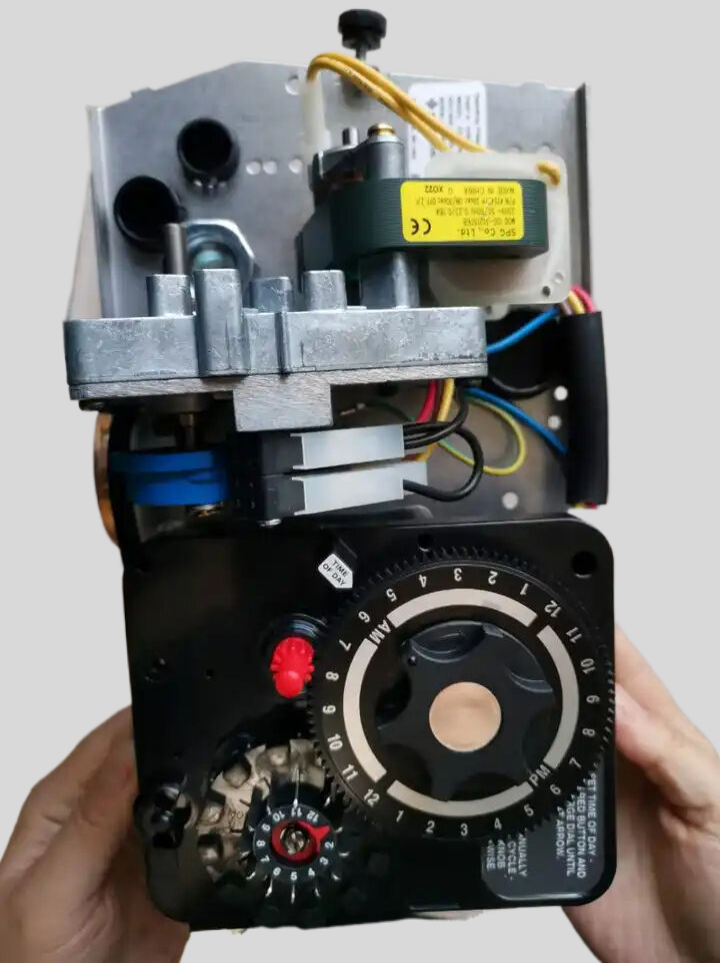

The heart of the electronic air valve control system is the solenoid, an electromagnetic device that converts electrical energy into mechanical motion. When an electric current is passed through the solenoid, it creates a magnetic field that moves a plunger inside the valve. This movement opens or closes the valve, thereby controlling the flow of air or gas.

| Mode | MF2 | MF2-H | MF4 | MF4-B | MF10 | AF2 & AF2-H | AF4 | AF10 |

| Regeneration mode | Manual | Automatic | ||||||

| Timer by day: 0-99days | ||||||||

| Timer by hours: 0-99hours | ||||||||

| Inlet | 3/4” | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1” | 2” |

| Outlet | 3/4” | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1” | 2” |

| Drain | 3/4” | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1” | 2” |

| Base | 2-1/2” | 2-1/2” | 2-1/2” | 2-1/2” | 4” | 2-1/2” | 2-1/2” | 4” |

| Riser pipe | 1.05”OD | 1.05”OD | 1.05”OD | 1.05”OD | 1.5”D-GB | 1.05”OD | 1.05”OD | 1.5”D-GB |

| Water Capacity | 2m3/h | 2m3/h | 4m3/h | 4m3/h | 10m3/h | 2m3/h | 4m3/h | 10m3/h |

| Working Pressure | 0.15-0.6MPa | |||||||

| Working Temperature | 5-50 °C | |||||||

| Power Supply | AC100-240V/50-60Hz DC12V-1.5A | |||||||

The operation of the electronic air valve control system is governed by the engine control unit (ECU), a computerized component that monitors and manages various aspects of the engine’s operation. The ECU receives data from various sensors located throughout the engine. These sensors provide information about the engine’s operating conditions, such as its speed, temperature, and load.

Based on this data, the ECU calculates the optimal amount of air required for combustion and sends a corresponding electrical signal to the solenoid in the air valve control system. The solenoid then adjusts the position of the valve to allow the precise amount of air into the combustion chamber.

One of the significant advantages of electronic air valve control systems is their precision and responsiveness. They can adjust the air flow in real-time, responding to changes in the engine’s operating conditions almost instantaneously. This capability allows for more efficient combustion, which in turn leads to improved engine performance, better fuel economy, and reduced emissions.

However, like any other mechanical system, electronic air valve control systems are not immune to failure. Common issues include solenoid malfunctions and sensor failures, which can lead to inaccurate air flow control. Regular inspections and maintenance are therefore essential to ensure the system’s optimal performance and longevity.

In conclusion, electronic air valve control is a sophisticated system that plays a vital role in engine operation. It uses advanced electromechanical technology to precisely control the flow of air into the combustion chamber, enhancing engine performance and efficiency. Despite its complexity, the system is highly reliable and durable, making it a cornerstone of modern engine technology. As technology continues to evolve, we can expect to see even more advanced and efficient air valve control systems in the future.

The Impact of Electronic Air Valve Control on HVAC Efficiency

Electronic air valve control is a technological innovation that has significantly impacted the efficiency of Heating, Ventilation, and Air Conditioning (HVAC) systems. This technology has revolutionized the way HVAC systems operate, leading to improved performance, energy efficiency, and cost savings.

The primary function of an electronic air valve control is to regulate the flow of air in an HVAC system. It does this by adjusting the opening and closing of the air valves based on the system’s requirements. This precise control over the air flow results in a more efficient operation of the HVAC system.

| GL-1 | ||||

| Model | GL2-1/ GL2-1 LCD | GL4-1/ GL4-1 LCD | GL10-1 Top Loading | GL10-1 Side Loading |

| Output Max | 4T/H | 7T/H | 15T/H | 15T/H |

Traditionally, HVAC systems operated on a fixed air flow rate, which often led to energy wastage. However, with the advent of electronic air valve control, HVAC systems can now adjust the air flow rate based on the actual demand. This means that the system only uses the amount of energy required to maintain the desired temperature, thereby reducing energy consumption and costs.

Moreover, electronic air valve control also enhances the comfort level within a building. By accurately controlling the air flow, it ensures a consistent temperature throughout the building. This eliminates the problem of hot and cold spots, which are common in buildings with traditional HVAC systems.

Another significant advantage of electronic air valve control is its ability to improve indoor air quality. By controlling the amount of fresh air that enters the building, it helps to maintain a healthy indoor environment. This is particularly important in today’s world, where people spend a significant amount of time indoors.

Furthermore, electronic air valve control also contributes to the longevity of the HVAC system. By preventing the system from operating at full capacity all the time, it reduces wear and tear on the system’s components. This not only extends the lifespan of the HVAC system but also reduces maintenance costs.

The integration of electronic air valve control with building automation systems has further enhanced its impact on HVAC efficiency. Through this integration, the HVAC system can be controlled remotely, allowing for real-time adjustments based on changing conditions. This level of control and flexibility is unprecedented and has set a new standard for HVAC efficiency.

However, despite the numerous benefits of electronic air valve control, its implementation is not without challenges. The initial cost of installing this technology can be high, and it requires skilled technicians for installation and maintenance. Additionally, there may be compatibility issues with existing HVAC systems, which could require additional modifications.

Nevertheless, the long-term benefits of electronic air valve control far outweigh these challenges. The energy savings alone can offset the initial investment in a relatively short period. Moreover, the improved comfort and air quality can lead to increased productivity and well-being for the occupants of the building.

In conclusion, electronic air valve control has had a profound impact on HVAC efficiency. It has transformed the way HVAC systems operate, leading to significant improvements in energy efficiency, comfort, and indoor air quality. Despite the challenges associated with its implementation, the benefits of this technology make it a worthwhile investment for any building owner or manager. As we continue to strive for more sustainable and efficient buildings, electronic air valve control will undoubtedly play a crucial role in achieving these goals.