Table of Contents

Benefits of Using an Ep 10 conductivity meter in Industrial Applications

In industrial applications, the measurement of conductivity is crucial for ensuring the quality and efficiency of processes. One of the most reliable tools for measuring conductivity is the Ep 10 conductivity meter. This advanced instrument offers a range of benefits that make it an essential tool for industrial settings.

One of the key advantages of the Ep 10 conductivity meter is its accuracy. With a high level of precision, this meter can provide accurate readings of conductivity levels in a variety of substances. This is essential for ensuring that processes are running smoothly and that products meet quality standards. The Ep 10 conductivity meter is also highly sensitive, allowing it to detect even small changes in conductivity levels.

Another benefit of the Ep 10 conductivity meter is its versatility. This meter can be used in a wide range of industrial applications, from water treatment plants to chemical processing facilities. Its ability to measure conductivity in liquids of varying viscosities and temperatures makes it a valuable tool for a variety of industries. Additionally, the Ep 10 conductivity meter is easy to use, with a user-friendly interface that allows for quick and efficient measurements.

In addition to its accuracy and versatility, the Ep 10 conductivity meter is also highly durable. Constructed from high-quality materials, this meter is designed to withstand the rigors of industrial environments. Its robust construction ensures that it can continue to provide accurate readings even in harsh conditions. This durability makes the Ep 10 conductivity meter a reliable tool for long-term use in industrial settings.

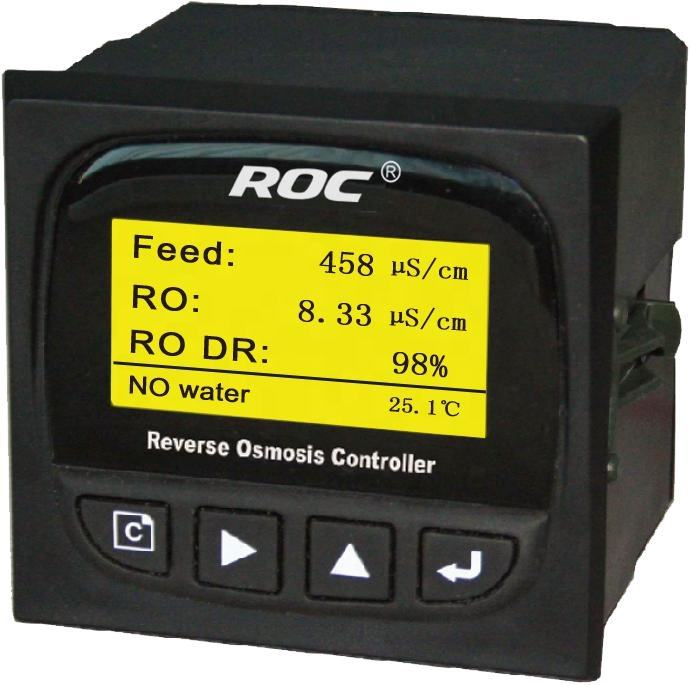

One of the key features of the Ep 10 conductivity meter is its advanced technology. This meter is equipped with state-of-the-art sensors and electronics that allow for precise and reliable measurements. Its digital display provides clear and easy-to-read results, making it simple to interpret conductivity levels. The Ep 10 conductivity meter also offers a range of customizable settings, allowing users to tailor measurements to their specific needs.

The Ep 10 conductivity meter is also highly efficient, with fast response times that allow for quick measurements. This efficiency is essential for maintaining productivity in industrial settings, where time is often of the essence. The Ep 10 conductivity meter can provide rapid results, allowing for timely adjustments to processes and ensuring that operations run smoothly.

Overall, the Ep 10 conductivity meter offers a range of benefits that make it an essential tool for industrial applications. From its accuracy and versatility to its durability and efficiency, this meter is designed to meet the needs of modern industrial settings. With its advanced technology and user-friendly interface, the Ep 10 conductivity meter is a reliable and effective tool for measuring conductivity in a variety of substances. Whether used in water treatment plants, chemical processing facilities, or other industrial settings, the Ep 10 conductivity meter is a valuable asset for ensuring the quality and efficiency of processes.

How to Properly Calibrate and Maintain an Ep 10 conductivity meter

An Ep 10 conductivity meter is a valuable tool used in various industries to measure the conductivity of a solution. Proper calibration and maintenance of this device are essential to ensure accurate and reliable readings. In this article, we will discuss the steps involved in calibrating and maintaining an Ep 10 conductivity meter to ensure its optimal performance.

| Model | CCT-3300 Series Conductivity Online Controller |

| Constant | 0.01cm-1, 0.1 cm-1, 1.0cm-1, 10.0 cm-1 |

| Conductivity | (0.5~20)mS/cm,(0.5~2,000)uS/cm, (0.5~200)uS/cm, (0.05~18.25)MQ\u00b7cm |

| TDS | (250~10,000)ppm, (0.5~1,000)ppm, (0.25~100)ppm |

| Medium Temp. | (0~50)\u2103 |

| Resolution | Conductivity: 0.01uS/cm, TDS:0.01ppm, Temp.: 0.1\u2103 |

| Accuracy | Conductivity: 1.5%(FS), Resistivity:2.0%(FS), TDS: 1.5%(FS), Temp.: +/-0.5\u2103 |

| Temp. compensation | (0-50)\u00b0C (with 25\u2103 as Standard) |

| Cable length | \u22645m(MAX) |

| mA output | Isolated (4~20)mA, Instrument / Transmitter for selection |

| Control Output | relay contact: ON/OFF, Load capacity: AC 230V/5A(Max) |

| Working Environment | Temp.(0~50)\u2103;Relative Humidity \u226485%RH (none condensation) |

| Storage Environment | Temp.(-20~60)\u2103;Relative Humidity \u226485%RH (none condensation) |

| Power Supply | CCT-3300:DC 24V; CCT-3310: AC 110V; CCT-3320: AC 220V |

| Dimension | 48mmx96mmx80mm(HxWxD) |

| Hole Size | 44mmx92mm(HxW) |

| Installation | Panel mounted, fast installation |

Calibration is the process of adjusting the meter to ensure that it provides accurate readings. To calibrate an Ep 10 conductivity meter, you will need a calibration standard solution with a known conductivity value. Start by rinsing the conductivity cell with deionized water to remove any residue. Then, immerse the cell in the calibration standard solution and allow it to stabilize. Adjust the meter’s calibration settings until it displays the correct conductivity value of the standard solution. Repeat this process with multiple standard solutions to ensure the accuracy of the meter across a range of conductivity values.

Regular maintenance is crucial to keep the Ep 10 conductivity meter in good working condition. One important aspect of maintenance is cleaning the conductivity cell. Over time, the cell can become contaminated with residue from the solutions being measured, which can affect the accuracy of the readings. To clean the cell, soak it in a solution of diluted acid or detergent, then rinse it thoroughly with deionized water. Be sure to handle the cell carefully to avoid damaging the delicate electrodes.

In addition to cleaning the conductivity cell, it is also important to check the overall condition of the meter regularly. Inspect the electrodes for any signs of damage or wear, such as corrosion or pitting. If any issues are found, replace the electrodes as soon as possible to ensure accurate readings. It is also a good idea to check the meter’s battery and replace it if necessary to prevent any interruptions in operation.

Proper storage of the Ep 10 conductivity meter is another important aspect of maintenance. When not in use, store the meter in a clean, dry place away from direct sunlight and extreme temperatures. Avoid storing the meter in humid environments, as this can lead to corrosion and damage. It is also a good idea to store the meter in its protective case to prevent any accidental damage.

Regular calibration and maintenance of an Ep 10 conductivity meter are essential to ensure accurate and reliable readings. By following the steps outlined in this article, you can keep your meter in optimal working condition and prolong its lifespan. Remember to calibrate the meter regularly with standard solutions, clean the conductivity cell, check the overall condition of the meter, and store it properly when not in use. By taking these simple steps, you can ensure that your Ep 10 conductivity meter continues to provide accurate measurements for years to come.