“Measure, monitor, and manage your water quality with ease using the orp meter.”

Understanding the Basics of orp meter Technology

Oxidation-Reduction Potential (ORP) meters are essential tools used in various industries, including water treatment, aquaculture, and food processing. These devices measure the ability of a solution to oxidize or reduce substances, providing valuable information about the quality and purity of the liquid being tested. Understanding how orp meters work is crucial for ensuring accurate and reliable measurements.

At the heart of an orp meter is a probe that contains a reference electrode and a measuring electrode. The reference electrode is typically made of silver/silver chloride, while the measuring electrode is made of platinum or gold. When the probe is immersed in a solution, a potential difference is generated between the two electrodes, which is measured by the meter.

The ORP value is expressed in millivolts (mV) and indicates the tendency of a solution to either gain or lose electrons. A positive ORP value indicates that the solution is oxidizing, meaning it has a high potential to accept electrons. Conversely, a negative ORP value indicates that the solution is reducing, meaning it has a high potential to donate electrons.

orp meters work on the principle of redox reactions, where one substance is oxidized (loses electrons) while another is reduced (gains electrons). By measuring the ORP value of a solution, users can determine its overall redox potential and assess its ability to support chemical reactions or microbial growth.

orp meters are used in a wide range of applications, from monitoring water quality in swimming pools to controlling the oxidation-reduction reactions in industrial processes. In water treatment, orp meters are used to monitor the disinfection process by measuring the effectiveness of chlorine or other oxidizing agents in killing bacteria and other pathogens.

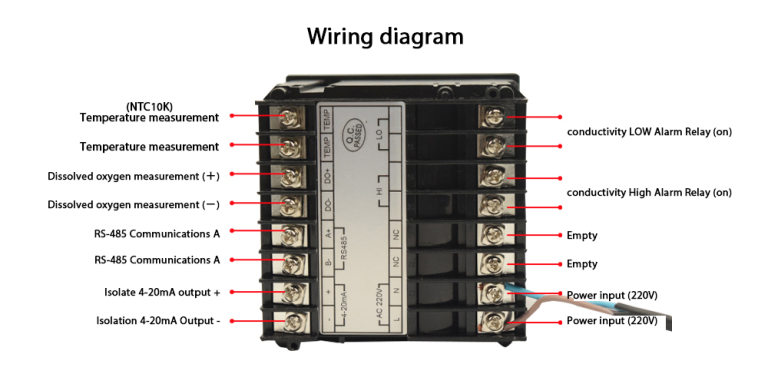

| CCT-3300 | ||||

| Constant | 10.00cm-1 | 1.000cm-1 | 0.100cm-1 | 0.010cm-1 |

| Conductivity | (500~20,000) | (1.0~2,000) | (0.5~200) | (0.05~18.25) |

| μS/cm | μS/cm | μS/cm | MΩ·cm | |

| TDS | (250~10,000) | (0.5~1,000) | (0.25~100) | —— |

| ppm | ppm | ppm | ||

| Medium Temp. | (0~50)℃(Temp. Compensation : NTC10K) | |||

| Resolution | Conductivity: 0.01μS/cm;0.01mS/cm | |||

| TDS: 0.01ppm | ||||

| Temp.: 0.1℃ | ||||

| Accuracy | Conductivity:1.5%(FS) | |||

| Resistivity: 2.0%(FS) | ||||

| TDS:1.5%(FS) | ||||

| Temp:±0.5℃ | ||||

| Analog Output | Single isolated(4~20)mA,instrument/transmitter for selection | |||

| Control Output | SPDT relay,Load Capacity: AC 230V/50A(Max) | |||

| Working Environment | Temp: (0~50)℃;Relative humidity: ≤85%RH(none condensation) | |||

| Storage Environment | Temp:(-20~60)℃; Relative humidity ≤85%RH(none condensation) | |||

| Power Supply | DC 24V/AC 110V/AC 220V±15%(for selection) | |||

| Dimension | 48mm×96mm×80mm (H×W×D) | |||

| Hole Size | 44mm×92mm (H×W) | |||

| Installation | Panel mounted, fast installation | |||

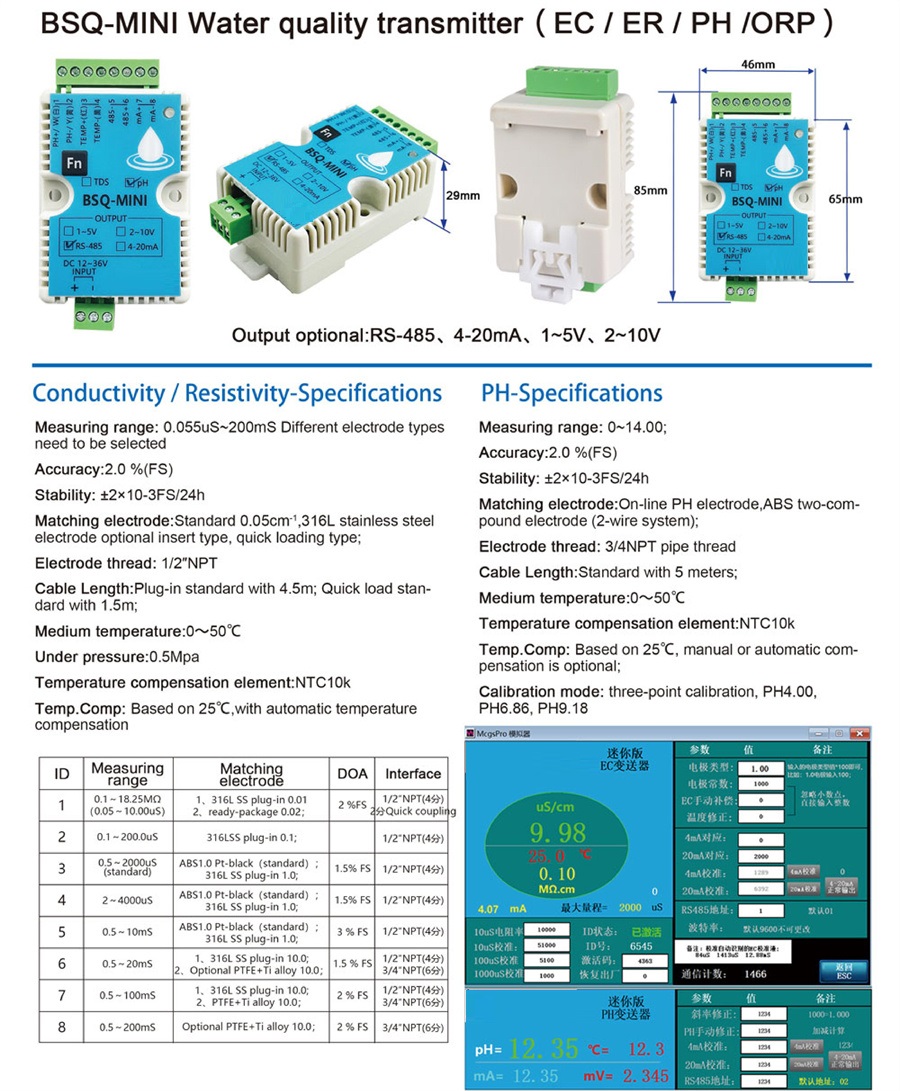

| Model | pH/ORP-810 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~50℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×100mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In aquaculture, orp meters are used to monitor the water quality in fish tanks and ponds, ensuring that the environment is suitable for fish growth and health. By maintaining the proper ORP levels, aquaculturists can prevent the growth of harmful bacteria and ensure the well-being of their aquatic animals.

In food processing, orp meters are used to monitor the oxidation-reduction reactions that occur during fermentation, curing, and other processes. By measuring the ORP value of the food product, manufacturers can ensure that the desired chemical reactions are taking place and that the product meets quality standards.

In conclusion, orp meters are valuable tools for measuring the redox potential of solutions in various industries. By understanding how orp meters work and how to calibrate and maintain them properly, users can obtain accurate and reliable measurements for a wide range of applications. Whether monitoring water quality, controlling chemical reactions, or ensuring food safety, orp meters play a crucial role in maintaining the quality and purity of liquids.