No products were found matching your selection.

Other Related Products

-

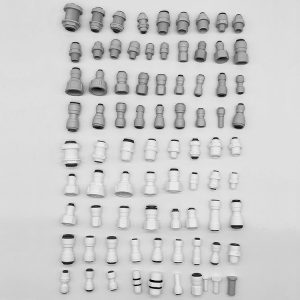

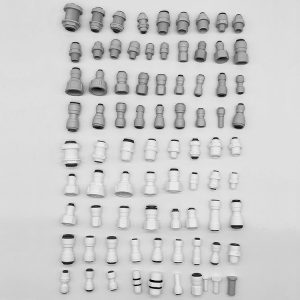

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

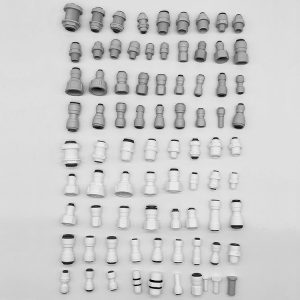

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

1) Working Position : Filter->Back Wash 1->Back wash 2->Fast Rinse->Filter

2) Using ceramic moving valve disk, small rotation torque.

3) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

4) It could be operated with pressure directly.

-

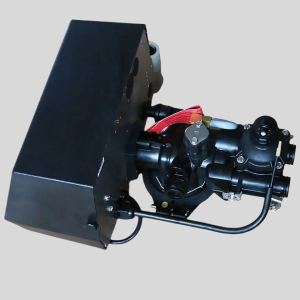

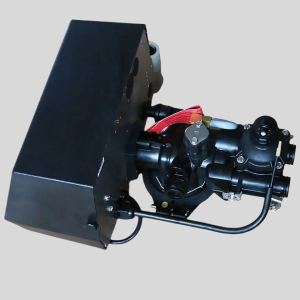

Fully adjustable, 5-cycle control delivers upflow backwash, downflow brining, slow rinse, rapid rinse, brine refill, and downflow service

Time-tested, hydraulically-balanced piston, seal and spacer, controls service flow and regeneration

Non-corrosive, fiber-reinforced polymer construction

Excellent flow rates (19 GPM continuous, 24 GPM peak)

Backwash capacity handles tanks up to 16″ diameter for softener, and filter

-

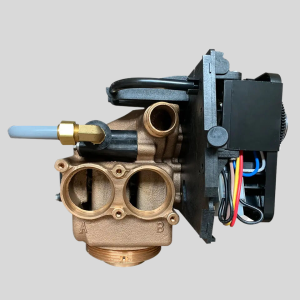

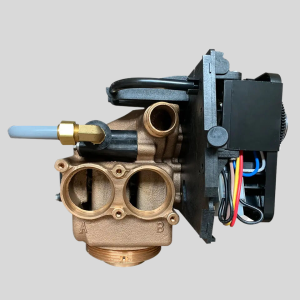

Easily-adjustable, 5-cycle, downflow-brining control

Rugged, long-life construction features a lead-free brass valve body

Uses conditioned water for regeneration

-

1) Downflow type.

2) Working Position : Service->Back Wash->Brine and slow rinse->Fast Rinse->Refill->Service .

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly

-

High Cost-Effective ,widely used for chemical industry,paper making industry,industrial coating,pharmaceutical,food,beverage,municipal water,Environmental and so on.

-

1) Automatic softener valve Upflow type with refill softener water.

2) Upflow Working Position :

Service->Back Wash->Upflow Brine and slow rinse->Refill the softener water ->Fast rinse->Service.

3) Using ceramic moving valve disk, small rotation torque

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly

-

On-line analysis and process control of the oil refining, metallurgy,chemical synthesis industry process;