No products were found matching your selection.

Other Related Products

-

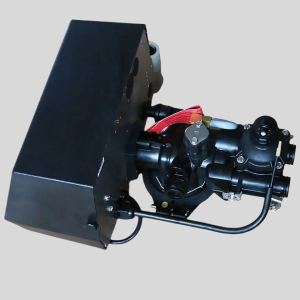

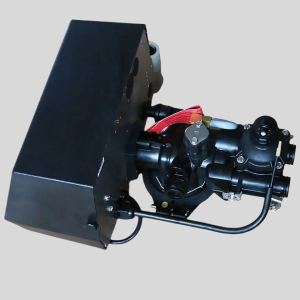

1) Downflow type.

2) Working Position : Service->Back Wash->Brine and slow rinse->Fast Rinse->Refill->Service .

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly

-

Meter, time clock dual mode. In flow mode, the internal flow transmitter realizes the function of setting water volume as required. After setting regeneration water volume and cleaning water volume of exchange tank, the period of softening water amount (ton) according to the hardness of the raw water, each station decreases to “0” according to the set value, and stops decreasing and maintains when the water is out of service or no water.

-

FL-9900 flow transmitter adopts all-digital circuit design, which has the characteristics of simple circuit structure, high precision, good reproducibility, strong anti-interference ability, high protection level, easy installation and use. Widely used in water treatment, cooling water, chemical, biopharmaceutical, power plants, cement plants, sewage treatment, colleges and universities, research institutes and other industrial processes real-time, on-line monitoring of fluids。

-

GR20\40\50\20T\40T series up flow regeneration fixed bed large valve series, water production range is 15T/ h-70t /h, the inlet flow meter is used to set the cycle of water production, slow backwash water and wash water, and the brine flow meter and the brine electric valve are used to specifically measure brine absorption and salt tank water supply.In the flow mode, the internal flow transducer realizes the switch of all stations as long as the amount of brine,the amount of slow washing water and the amount of washing water is set according to the volume (liter) of the swap tank. After the period of softening water amount (ton) is set according to the hardness of the raw water, each station decreases to “0” according to the set value, and stops decreasing and maintains when the water is out of service or no water.

-

Fully adjustable, 5-cycle control delivers upflow backwash, downflow brining, slow rinse, rapid rinse, brine refill, and downflow service

Time-tested, hydraulically-balanced piston, seal and spacer, controls service flow and regeneration

Non-corrosive, fiber-reinforced polymer construction

Excellent flow rates (19 GPM continuous, 24 GPM peak)

Backwash capacity handles tanks up to 16″ diameter for softener, and filter

-

Applicable to all kinds of small and medium-sized single-stage, double-stage reverse osmosis control system. With simple operation, complete measurement and configuration, highly integrated system

-

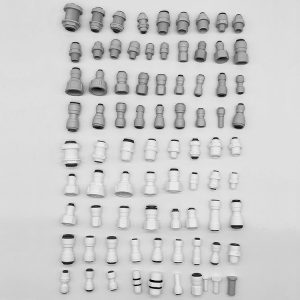

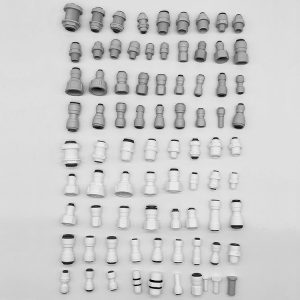

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

Widely used for electric power,electronics,metallurgy,petrochemical,pharmaceutical ,food and beverage,environmental protection field .

-

“One Dynamic and Two Static” Double Static Ceramics Plates Multi-port Valve is on behalf of another beginning in the field of water treatment control, which can overcome many disadvantages of traditional products in installation.