pH/ORP-3500 series pH/ORP Online Meter

One kind of popular and cost-effective online pH/ORP controller.

One kind of popular and cost-effective online pH/ORP controller.

Meter, time clock dual mode. In flow mode, the internal flow transmitter realizes the function of setting water volume as required. After setting regeneration water volume and cleaning water volume of exchange tank, the period of softening water amount (ton) according to the hardness of the raw water, each station decreases to “0” according to the set value, and stops decreasing and maintains when the water is out of service or no water.

This series instruments are widely used for online pH/ORP monitoring in environment protection water treatment, pure water treatment, industrial process and so on.

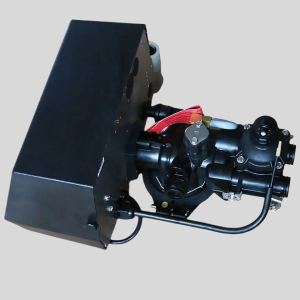

Incorporates 2 time-tested, hydraulically-balanced pistons to independently pilot service flow and regeneration

For use with single or multiple tank systems

Backwashes softener tanks up to 36″ diameter

Continuous flow rate of 106 GPM

Fully adjustable, 5-cycle control delivers upflow backwash, downflow brining, slow rinse, rapid rinse, brine refill, and downflow service

Time-tested, hydraulically-balanced piston, seal and spacer, controls service flow and regeneration

Non-corrosive, fiber-reinforced polymer construction

Excellent flow rates (19 GPM continuous, 24 GPM peak)

Backwash capacity handles tanks up to 16″ diameter for softener, and filter

Applicable to all kinds of small and medium-sized single-stage, double-stage reverse osmosis control system. With simple operation, complete measurement and configuration, highly integrated system

Typical applications • Widely used in thermal boiler deaerator water and large and medium-sized industrial boiler feed water; • Operational supervision of reactor Primary circuit, secondary circuit circuits and condensate system; • On-line analysis of dissolved oxygen in circulating water of heat exchange system; • Deaeration control of marine fresh water system, thermal system and…

FLECK control valve 5600 softening water equipment generally uses fixed bed downstream

regeneration, the working process is operation, backwashing, regeneration, replacement,

positive washing, salt tank water injection.

1) Automatic softener valve Downflow and upflow type.

2) Downflow & Upflow Working Position :

a) Service->Back Wash->Downflow Brine and slow rinse->Refill ->Fast rinse->Service.

b) Service->Back Wash->Upflow Brine and slow rinse->Refill ->Fast rinse->Service.

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly.