Table of Contents

Understanding the Advanced Technology Behind Filtrex Filters

Filtrex Filters, a leading name in the filtration industry, has been consistently delivering high-quality products that cater to a wide range of applications. The advanced technology behind Filtrex Filters is what sets them apart from their competitors, ensuring superior performance and longevity. This article aims to provide an in-depth understanding of the sophisticated technology that powers these filters.

Filtrex Filters are designed with a unique blend of innovation and expertise. The company employs cutting-edge technology to manufacture filters that not only meet but exceed industry standards. The primary focus is on ensuring the highest level of filtration efficiency, which is achieved through the use of advanced materials and innovative design techniques.

One of the key elements that contribute to the superior performance of Filtrex Filters is the use of synthetic media. This material is known for its high dirt-holding capacity, which ensures that the filters can effectively trap and hold a large amount of particulate matter. The synthetic media also boasts excellent resistance to moisture, which significantly enhances the lifespan of the filters.

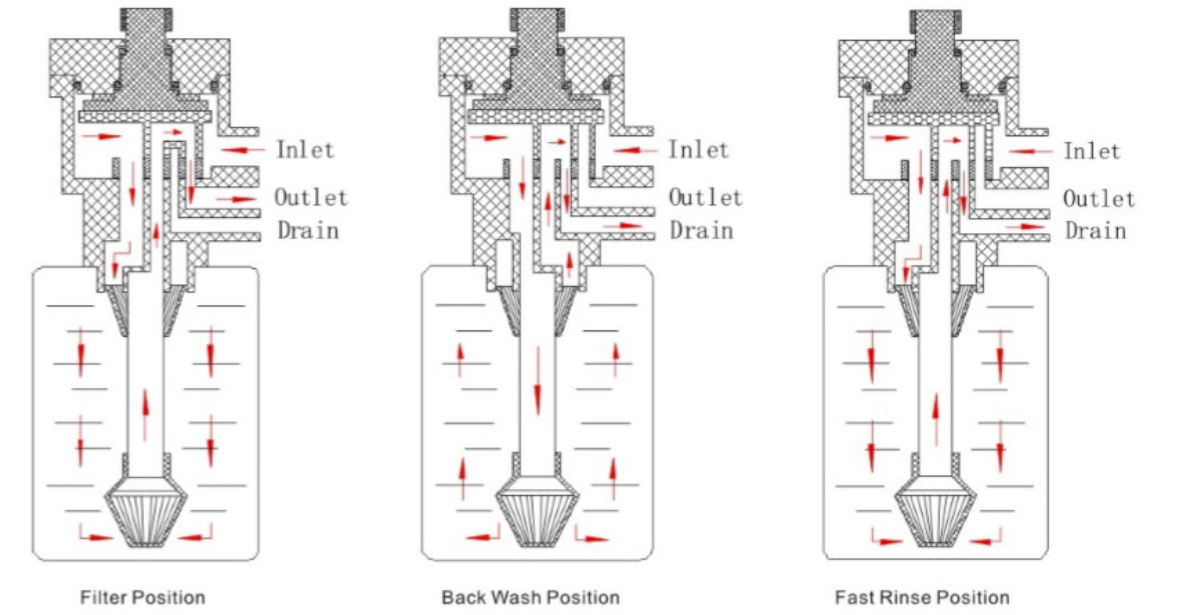

In addition to the synthetic media, Filtrex Filters also incorporate pleated design technology. This design increases the surface area of the filter, allowing it to capture more contaminants. The pleats are evenly spaced and rigidly maintained to prevent collapse or deformation under high pressure. This ensures consistent filtration performance, even under demanding conditions.

Another noteworthy aspect of Filtrex Filters is the use of advanced bonding techniques. The components of the filter are securely bonded using high-quality adhesives, ensuring a tight seal that prevents unfiltered air or fluid from bypassing the filter media. This meticulous attention to detail contributes to the overall reliability and effectiveness of the filters.

| GL-1 | ||||

| Model | GL2-1/ GL2-1 LCD | GL4-1/ GL4-1 LCD | GL10-1 Top Loading | GL10-1 Side Loading |

| Output Max | 4T/H | 7T/H | 15T/H | 15T/H |

Filtrex Filters also employ a unique end cap design. The end caps are made from durable materials that can withstand high pressure and temperature variations. They are designed to provide a perfect fit, ensuring a secure seal and preventing leakage. This design not only enhances the performance of the filters but also simplifies the installation process.

The advanced technology behind Filtrex Filters is complemented by rigorous testing procedures. Each filter undergoes a series of tests to verify its performance and durability. These tests include efficiency testing, capacity testing, and burst pressure testing, among others. The results of these tests provide a reliable measure of the filter’s ability to perform under real-world conditions.

In conclusion, the advanced technology behind Filtrex Filters is a testament to the company’s commitment to quality and innovation. The use of synthetic media, pleated design, advanced bonding techniques, and unique end cap design, coupled with rigorous testing, ensures that Filtrex Filters deliver superior filtration performance. Whether it’s for automotive, industrial, or residential applications, Filtrex Filters provide a reliable and efficient solution for all your filtration needs.

Maximizing Efficiency: A Comprehensive Guide to Filtrex Filters

Filtrex Filters, a leading name in the filtration industry, has been providing high-quality filtration solutions for a variety of applications for many years. The company’s commitment to innovation and quality has made it a preferred choice for many businesses and individuals seeking efficient and reliable filtration systems. This article aims to provide a comprehensive guide on how to maximize the efficiency of Filtrex Filters.

Filtrex Filters are designed with advanced technology to ensure optimal performance. They are made from high-quality materials that guarantee durability and longevity. However, to maximize their efficiency, proper usage and maintenance are crucial.

Firstly, it is essential to select the right filter for your specific needs. Filtrex offers a wide range of filters, each designed for a particular application. For instance, if you need a filter for a high-temperature environment, Filtrex has filters made from materials that can withstand high temperatures without compromising their performance. Similarly, if you require a filter for a corrosive environment, Filtrex provides filters made from corrosion-resistant materials. Therefore, understanding your specific needs and selecting the appropriate filter is the first step towards maximizing efficiency.

Secondly, proper installation of the filter is vital. Incorrect installation can lead to leaks, which can reduce the filter’s efficiency and potentially damage the system. Therefore, it is recommended to follow the manufacturer’s instructions for installation. If you are unsure about the installation process, it may be beneficial to hire a professional to ensure the filter is installed correctly.

| Model | Category | Water Capacity m3/h | LCD | LED | ICON | DIODE |

| CV-2 | Automatic Drain Valve | 0.5 |

Thirdly, regular maintenance of the filter is key to maintaining its efficiency. Over time, filters can become clogged with particles, which can reduce their performance. Therefore, it is recommended to clean or replace the filter regularly, depending on the manufacturer’s instructions. Regular maintenance not only ensures optimal performance but also extends the lifespan of the filter.

Moreover, monitoring the filter’s performance can help identify any issues early on. If you notice a decrease in the filter’s efficiency, it may be due to a clog or damage to the filter. In such cases, it is advisable to inspect the filter and address the issue promptly to prevent further damage and maintain efficiency.

Lastly, it is important to consider the environmental conditions in which the filter operates. Factors such as temperature, humidity, and the presence of corrosive substances can affect the filter’s performance. Therefore, it is advisable to ensure the filter is suitable for the operating conditions and to take necessary precautions to protect the filter from adverse conditions.

In conclusion, maximizing the efficiency of Filtrex Filters involves selecting the right filter, proper installation, regular maintenance, performance monitoring, and considering the operating conditions. By following these steps, you can ensure that your Filtrex Filter operates at its optimal efficiency, providing you with reliable and effective filtration solutions. Remember, a well-maintained filter not only performs better but also lasts longer, providing you with better value for your investment.