Table of Contents

Maintenance Tips for Fleck 5600 Motor

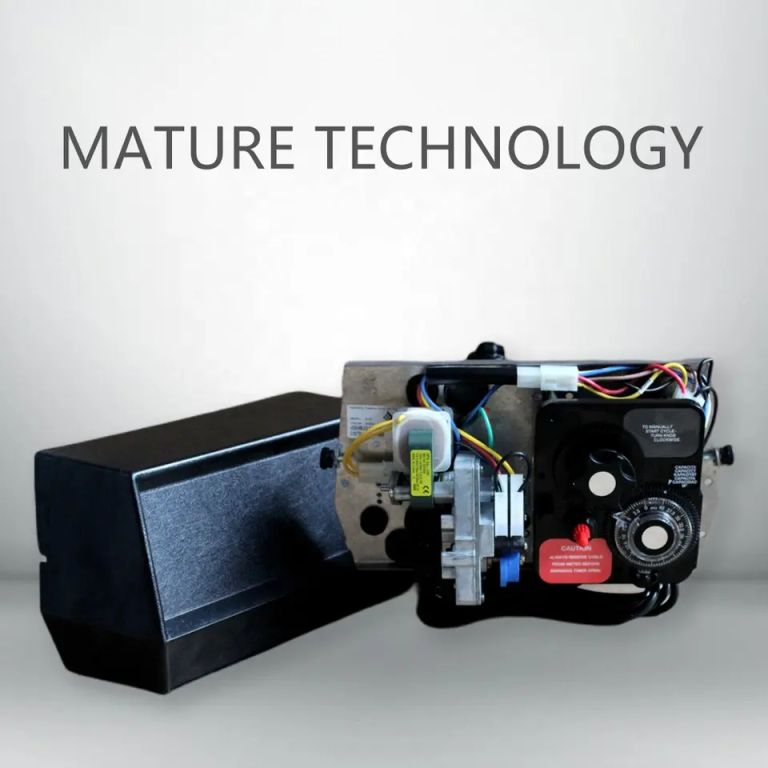

The Fleck 5600 motor is a crucial component of your water softener system, responsible for controlling the regeneration process that keeps your water softener running efficiently. Regular maintenance of the Fleck 5600 motor is essential to ensure that your water softener continues to operate effectively and provide you with soft water for your household needs.

One of the most important maintenance tasks for the Fleck 5600 motor is to regularly check and clean the motor and its components. Over time, dirt, debris, and mineral buildup can accumulate on the motor, causing it to work harder and less efficiently. By cleaning the motor and its components regularly, you can help prevent these issues and ensure that your water softener continues to function properly.

When cleaning the Fleck 5600 motor, it is important to use a soft brush or cloth to gently remove any dirt or debris. Avoid using harsh chemicals or abrasive materials, as these can damage the motor and its components. Additionally, be sure to check the motor for any signs of wear or damage, such as frayed wires or loose connections, and address any issues promptly to prevent further damage.

Another important maintenance task for the Fleck 5600 motor is to regularly lubricate the motor and its moving parts. Proper lubrication helps reduce friction and wear on the motor, extending its lifespan and ensuring that it continues to operate smoothly. Be sure to use a lubricant that is recommended by the manufacturer and apply it according to the manufacturer’s instructions.

In addition to regular cleaning, checking electrical connections, and lubricating the motor, it is also important to monitor the performance of the Fleck 5600 motor and address any issues promptly. If you notice any unusual noises, vibrations, or other signs of trouble, it is important to investigate the issue and make any necessary repairs or adjustments. Ignoring these warning signs can lead to more serious problems down the line and may result in costly repairs or replacements.

By following these maintenance tips for the Fleck 5600 motor, you can help ensure that your water softener continues to operate effectively and provide you with soft water for your household needs. Regular cleaning, checking electrical connections, lubricating moving parts, and monitoring performance are all essential tasks that can help extend the lifespan of your water softener system and prevent costly repairs. If you are unsure how to perform any of these maintenance tasks, consult the manufacturer’s instructions or contact a professional for assistance. With proper care and maintenance, your Fleck 5600 motor can continue to provide you with soft water for years to come.

Troubleshooting Common Issues with Fleck 5600 Motor

The Fleck 5600 motor is a crucial component of water softening systems that rely on this brand of control valve. This motor is responsible for driving the valve’s movements, ensuring that the system operates efficiently and effectively. However, like any mechanical component, the Fleck 5600 motor can experience issues that may hinder its performance. In this article, we will discuss some common problems that users may encounter with the Fleck 5600 motor and provide troubleshooting tips to help resolve these issues.

One of the most common issues with the Fleck 5600 motor is a lack of movement or sluggish movement. This can be caused by a variety of factors, including a build-up of debris or sediment in the motor, a faulty electrical connection, or a worn-out motor. To troubleshoot this issue, start by checking the motor for any visible signs of debris or sediment. If present, carefully clean the motor using a soft brush or cloth to remove any obstructions that may be hindering its movement.

Next, inspect the electrical connections to ensure that they are secure and free of corrosion. If any connections appear loose or corroded, tighten them or replace them as needed. If the motor still does not move smoothly after cleaning and checking the connections, it may be time to replace the motor with a new one to restore proper functionality to the system.

Another common issue with the Fleck 5600 motor is excessive noise during operation. This can be caused by a variety of factors, including worn-out bearings, loose components, or improper alignment of the motor. To troubleshoot this issue, start by inspecting the motor for any loose or damaged components. Tighten any loose screws or bolts and replace any damaged parts to see if this resolves the noise issue.

If the noise persists, check the alignment of the motor to ensure that it is properly positioned within the system. Improper alignment can cause the motor to vibrate excessively, leading to noise during operation. Adjust the motor’s position as needed to see if this reduces the noise level. If the noise continues despite these efforts, it may be necessary to replace the motor with a new one to eliminate the issue.

In some cases, the Fleck 5600 motor may fail to start or stop as expected. This can be caused by a faulty electrical connection, a malfunctioning control board, or a worn-out motor. To troubleshoot this issue, start by checking the electrical connections to ensure that they are secure and free of corrosion. If any connections appear damaged or corroded, replace them to see if this resolves the problem.

Next, inspect the control board for any signs of damage or malfunction. If the control board is not functioning properly, it may prevent the motor from starting or stopping as expected. Replace the control board if necessary to restore proper operation to the system. If the motor still fails to start or stop after checking the connections and control board, it may be time to replace the motor with a new one to ensure reliable performance.

In conclusion, the Fleck 5600 motor is a critical component of water softening systems that rely on this brand of control valve. By understanding common issues that may arise with the motor and following the troubleshooting tips provided in this article, users can effectively address these problems and restore proper functionality to their systems. Whether dealing with sluggish movement, excessive noise, or failure to start or stop, taking the time to diagnose and resolve issues with the Fleck 5600 motor can help ensure that water softening systems operate efficiently and effectively for years to come.

| Model | Central tube | Drain | Brine tank connector | Base | Maximum power | Operating temperature\u00a0 |

| 9500 | 1.9″(1.5″) O.D. | 1″NPTF | 3/8″& 1/2″ | 4″-8UN | 8.9W | 1\u2103-43\u2103 |