Table of Contents

Advantages of Using YF-B5 Flow Sensor in Industrial Applications

Flow sensors are essential components in various industrial applications, providing accurate measurements of liquid flow rates. One popular choice among engineers and manufacturers is the YF-B5 flow sensor. This article will explore the advantages of using the YF-B5 flow sensor in industrial settings.

One of the key advantages of the YF-B5 flow sensor is its high level of accuracy. This sensor is designed to provide precise measurements of liquid flow rates, ensuring that industrial processes run smoothly and efficiently. With its reliable performance, the YF-B5 flow sensor helps to minimize errors and improve overall productivity in industrial applications.

In addition to its accuracy, the YF-B5 flow sensor is also known for its durability and longevity. Constructed from high-quality materials, this sensor is designed to withstand harsh operating conditions and maintain its performance over time. This durability makes the YF-B5 flow sensor a cost-effective choice for industrial applications, as it reduces the need for frequent replacements and repairs.

Another advantage of the YF-B5 flow sensor is its versatility. This sensor is compatible with a wide range of liquids, making it suitable for use in various industrial processes. Whether measuring the flow of water, chemicals, or other liquids, the YF-B5 flow sensor can provide accurate and reliable measurements, making it a versatile solution for industrial applications.

Furthermore, the YF-B5 flow sensor is easy to install and integrate into existing systems. With its compact design and simple installation process, this sensor can be quickly and easily incorporated into industrial equipment. This ease of installation helps to minimize downtime and disruption to operations, allowing for seamless integration of the YF-B5 flow sensor into industrial processes.

The YF-B5 flow sensor also offers real-time monitoring capabilities, allowing for immediate feedback on liquid flow rates. This real-time data can be used to optimize industrial processes, identify potential issues, and make informed decisions to improve efficiency and productivity. By providing accurate and timely information, the YF-B5 flow sensor helps to streamline operations and enhance overall performance in industrial settings.

Additionally, the YF-B5 flow sensor is designed with energy efficiency in mind. By accurately measuring liquid flow rates, this sensor helps to optimize energy usage and reduce waste in industrial processes. This energy-efficient design not only helps to lower operating costs but also contributes to sustainability efforts by minimizing resource consumption.

Overall, the YF-B5 flow sensor offers a range of advantages for industrial applications, including high accuracy, durability, versatility, ease of installation, real-time monitoring capabilities, and energy efficiency. With its reliable performance and cost-effective design, the YF-B5 flow sensor is a valuable tool for engineers and manufacturers looking to improve efficiency and productivity in their operations. Whether measuring water, chemicals, or other liquids, the YF-B5 flow sensor is a versatile and reliable solution for a wide range of industrial applications.

How to Calibrate and Maintain YF-B5 Flow Sensor for Accurate Readings

Flow sensors are essential devices used in various industries to measure the flow rate of liquids. The YF-B5 flow sensor is a popular choice due to its accuracy and reliability. However, like any other sensor, it requires calibration and maintenance to ensure accurate readings. In this article, we will discuss how to calibrate and maintain the YF-B5 flow sensor for optimal performance.

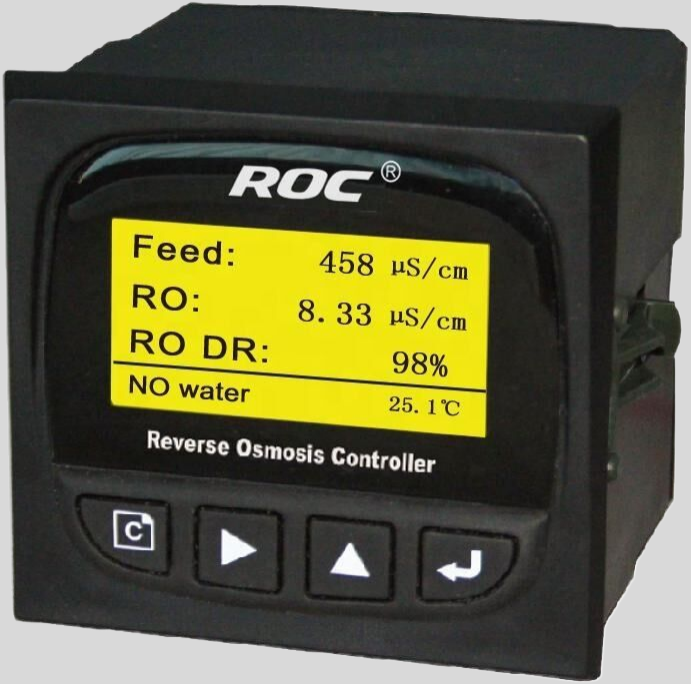

| ROS-2015 Single Stage Reverse Osmosis Program Controller | |

| \u3000 | 1.water source water tank without water protection |

| \u3000 | 2. low pressure protection |

| Acquisition signal | 3.pure water tank full protection |

| \u3000 | 4.high pressure protection |

| \u3000 | 5.external control(manual/automatic switch) |

| \u3000 | 1.water inlet valve |

| Output control | 2. flush valve |

| \u3000 | 3. low pressure pump |

| \u3000 | 4.high pressure pump |

| \u3000 | AC220v\u00b110% 50/60Hz |

| Power supply | AC110v\u00b110% 50/60Hz |

| \u3000 | DC24v\u00b110% |

| Control output | 5A/250V AC |

| Flush the way | Low pressure flush/ high pressure flush |

| Relative humidity | \u226485% |

| Ambient temperature | 0~50\u2103 |

| Hole Size | 45*92mm(high*wide) |

| Installation method | The embedded |

| Display usage | Standard RO process flow chart, supporting LED dynamic display |

| Process control | When the system is turned on for the first time,the system performs 30s membrane flushing,\u00a0 |

| instructions | and flush 10s when the machine is running and the water tank is full. Run continuously for 3h |

| \u3000 | or stand by for 3h when the water is full, automatically intervene in flushing for 10s |

Calibration is the process of adjusting the sensor to ensure that it provides accurate readings. To calibrate the YF-B5 flow sensor, you will need a known flow rate source, such as a flow meter or a pump with a flow rate indicator. Start by connecting the known flow rate source to the sensor and adjusting the sensor’s settings to match the flow rate. Once the sensor is calibrated, you can use it to measure the flow rate of liquids with confidence.

Regular maintenance is crucial to keep the YF-B5 flow sensor in good working condition. One of the most important maintenance tasks is cleaning the sensor regularly. Over time, dust, dirt, and other contaminants can build up on the sensor, affecting its accuracy. To clean the sensor, use a soft brush or cloth to remove any debris. Avoid using harsh chemicals or abrasive materials, as they can damage the sensor.

In addition to cleaning, it is also important to check the sensor for any signs of wear or damage. Inspect the sensor’s housing, connectors, and wiring for any cracks, corrosion, or other issues. If you notice any damage, replace the affected parts immediately to prevent further problems.

Another important aspect of maintaining the YF-B5 flow sensor is ensuring that it is properly installed. The sensor should be installed in a location where it can accurately measure the flow rate without any obstructions. Make sure that the sensor is securely mounted and that all connections are tight and secure.

Regularly calibrating and maintaining the YF-B5 flow sensor will help ensure accurate readings and reliable performance. By following these simple steps, you can prolong the life of the sensor and avoid costly repairs or replacements. Remember to always refer to the manufacturer’s instructions for specific calibration and maintenance procedures.

In conclusion, the YF-B5 flow sensor is a valuable tool for measuring the flow rate of liquids in various industries. To ensure accurate readings and reliable performance, it is important to calibrate and maintain the sensor regularly. By following the tips outlined in this article, you can keep your YF-B5 flow sensor in optimal condition and enjoy accurate flow rate measurements for years to come.