No products were found matching your selection.

Other Related Products

-

Widely used for chemical industry,pharmaceutical,food,beverage,industrial coating,municipal water,Environmental,etc.conductivity (resisitivity) online measuring and control. It is a small-scale, industry leading and High Cost-Effective conductivity/resistivity integration online controller.

-

Incorporates 2 time-tested, hydraulically-balanced pistons to independently pilot service flow and regeneration

For use with single or multiple tank systems

Backwashes softener tanks up to 36″ diameter

Continuous flow rate of 106 GPM

-

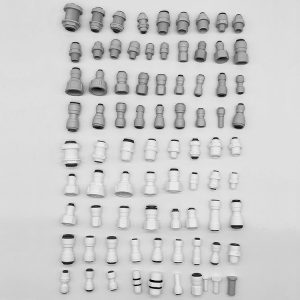

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

1). Automatic advance water softener valve Upflow type with empty salt cabinet technology.

2). Upflow Working Position :

a). Refill before regeneration: Service->Refill the softener water->Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Service .

b). Refill after regeneration: Service->Back Wash->Upflow Brine and slow rinse->Fast rinse->Refill the softener water->Service .

3). Using ceramic moving valve disk, small rotation torque.

4). Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5). It could be operated with pressure directly

-

DR20\40\50\20T\40T Soften valve series is floating bed, all appearance and geometric parameters and parts is the same as the corresponding GR20\40\50\20T\40T, floating bed has a good water quality, to adapt high hardness of the raw water, configuration swap tank should be fine and high, runing velocity in the 30-60 m/h, but resin filling rate must be above 90%, being stable working pressure,The floating bed is not suitable for frequent starting and changing water consumption.

-

FLECK control valve 5600 softening water equipment generally uses fixed bed downstream

regeneration, the working process is operation, backwashing, regeneration, replacement,

positive washing, salt tank water injection.

-

1. On-line analysis and process control of the oil refining, metallurgy, chemical synthesis industry process;

2. Water quality on-line analysis for the power industry, electronic industry, pharmaceutical industry, clinical equipment, food industry, beverage industry etc;

3. Online analysis and drug maintenance of the process for environmental monitoring, waste water treatment, water purification ;

4. Industry of the people’s livelihood, such as municipal water treatment, circulating cooling water, swimming pool management, scientific and technological agriculture;

5. The biological fermentation, industrial coating, chemical process experimental study.

-

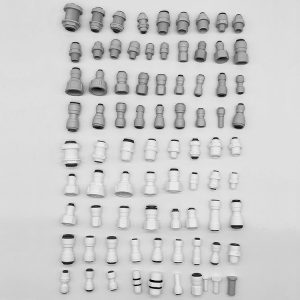

In-line Stem is widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

Widely used for electric power,electronics,metallurgy,petrochemical,pharmaceutical ,food and beverage,environmental protection field.