“Intake valves: the gateway to optimal engine performance.”

Understanding the Function of Intake Valves in an Engine

Intake valves are a crucial component of an engine’s operation, playing a vital role in the combustion process that powers the vehicle. Understanding how intake valves work is essential for anyone looking to gain a deeper insight into the inner workings of an engine.

Intake valves are responsible for allowing air and fuel to enter the combustion chamber of the engine. This process is essential for the combustion process to occur, as without a sufficient supply of air and fuel, the engine would not be able to generate the power needed to propel the vehicle forward.

When the piston in the engine moves downward during the intake stroke, the intake valve opens to allow a mixture of air and fuel to enter the combustion chamber. This mixture is then compressed by the piston during the compression stroke, before being ignited by the spark plug during the power stroke. The resulting explosion forces the piston back down, which in turn drives the crankshaft and ultimately powers the vehicle.

Intake valves are typically opened and closed by the camshaft, which is synchronized with the movement of the pistons in the engine. The camshaft is equipped with lobes that push against the valve stems, causing the valves to open and close at the appropriate times in the engine’s cycle.

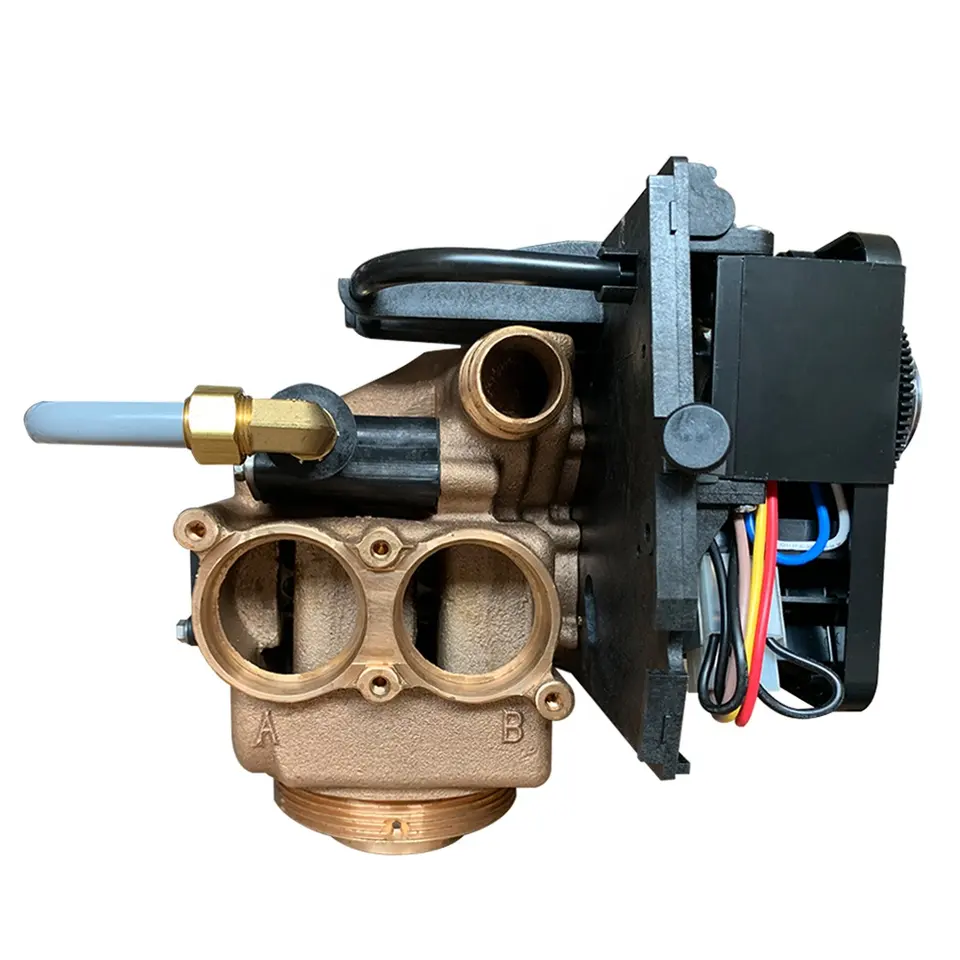

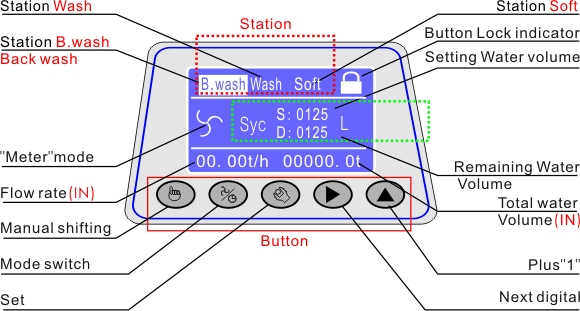

| Model | Valve Material | Inlet/Outlet | Continuous (0.1Mpa drop) | Peak (0.175Mpa drop) | Cv** | Maximum Backwash (0.175Mpa drop) | Distributor Pilot | Drain Line | Brine Line | Mounting Base | Height (from top of the tank) |

| CM39 | Unleaded brass | 3″ | 56.81m³/h | 73.86m³/h | 65 | 100gpm | 3″ | 2″(male) | 3/4″(male) | 6″-8UN or FLG | 15″ |

The timing of the intake valve opening and closing is crucial for the engine to operate efficiently. If the intake valve opens too early or too late, it can disrupt the combustion process and lead to a loss of power and efficiency. This is why modern engines are equipped with sophisticated timing systems that ensure the intake valves open and close at precisely the right moment.

In addition to timing, the size and shape of the intake valves also play a significant role in the engine’s performance. Larger intake valves allow for a greater volume of air and fuel to enter the combustion chamber, which can increase power output. However, larger valves can also reduce the engine’s efficiency at lower speeds, as they may not allow for optimal airflow at lower RPMs.

Intake valves are also subject to wear and tear over time, as they are constantly exposed to high temperatures and pressures during the combustion process. This can lead to issues such as valve sticking or valve burning, which can affect the engine’s performance and efficiency. Regular maintenance and inspection of the intake valves are essential to ensure they are operating correctly and to prevent any potential issues from arising.

In conclusion, intake valves are a critical component of an engine’s operation, allowing air and fuel to enter the combustion chamber and power the vehicle. Understanding how intake valves work is essential for anyone looking to gain a deeper insight into the inner workings of an engine. By ensuring that the intake valves are properly timed, sized, and maintained, you can help to maximize your engine’s performance and efficiency.