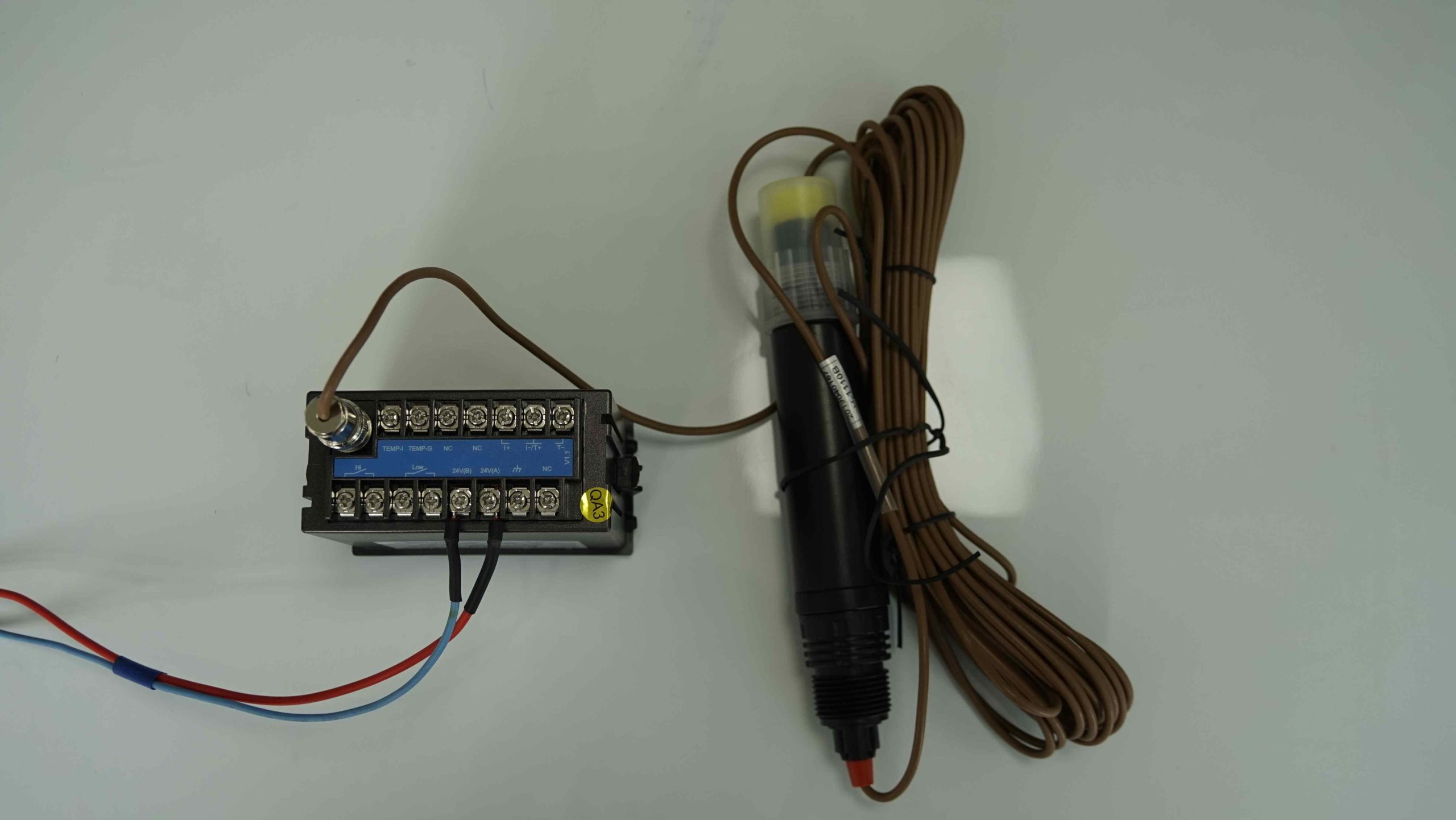

“Measure with precision, conductivity meter at work.”

Table of Contents

Principles of Conductivity Measurement

Conductivity meters are widely used in various industries to measure the ability of a solution to conduct electricity. This measurement is crucial in determining the concentration of ions in a solution, which can provide valuable information about the solution’s composition and purity. Understanding how a conductivity meter works is essential for anyone working in fields such as chemistry, environmental science, or water treatment.

At its core, a conductivity meter consists of two electrodes that are immersed in the solution being tested. When an electric current is applied to the electrodes, ions in the solution carry the current, allowing it to flow between the electrodes. The conductivity of the solution is directly proportional to the number of ions present, making it a reliable indicator of the solution’s overall ion concentration.

One of the key principles behind conductivity measurement is Ohm’s Law, which states that the current flowing through a conductor is directly proportional to the voltage applied across it. In the case of a conductivity meter, the voltage applied to the electrodes is typically kept constant, while the current flowing between the electrodes is measured. By measuring the current, the conductivity meter can calculate the solution’s conductivity, providing valuable information about its ion concentration.

To ensure accurate measurements, conductivity meters are often calibrated using standard solutions with known conductivity values. By comparing the readings obtained from these standard solutions to the known values, the meter can be adjusted to provide accurate and reliable measurements. This calibration process is essential for ensuring the accuracy of conductivity measurements and should be performed regularly to maintain the meter’s performance.

| Model | CCT-5300E series Conductivity/Resistivity/TDS Online Controller |

| Constant | 0.01cm-1, 0.1 cm-1, 1.0cm-1, 10.0 cm-1 |

| Conductivity | (0.5~20,000)uS/cm,(0.5~2,000)uS/cm, (0.5~200)uS/cm, (0.05~18.25)MQ·cm |

| TDS | (0.25~10,000)ppm, (0.25~1,000)ppm, (0.25~100)ppm |

| Medium Temp. | (0~50)℃(Temp.Compensation: NTC10K) |

| Accuracy | Conductivity: 1.5%(FS), Resistivity:2.0%(FS), TDS: 1.5%(FS), Temp.: +/-0.5℃ |

| Temp. compensation | (0-50)°C (with 25℃ as Standard) |

| Cable length | ≤20m(MAX) |

| mA output | Isolated, transportable (4~20)mA, Instrument / Transmitter for selection |

| Control Output | relay contact: ON/OFF, Load capacity: AC 230V/5A(Max) |

| Working Environment | Temp.(0~50)℃;Relative Humidity ≤85%RH (none condensation) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | CCT-5300E: DC 24V; CCT-5320E: AC 220V |

| Dimension | 96mmx96mmx105mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

| Installation | Panel mounted, fast installation |

In conclusion, conductivity meters are valuable tools for measuring the ion concentration of solutions in various industries. By understanding the principles behind conductivity measurement, including Ohm’s Law, calibration, electrode maintenance, and temperature compensation, users can ensure accurate and reliable measurements. Proper use and maintenance of conductivity meters are essential for obtaining meaningful data and making informed decisions based on conductivity measurements.

Factors Affecting Conductivity Measurements

Conductivity meters are widely used in various industries to measure the ability of a solution to conduct electricity. This measurement is crucial in determining the purity of water, monitoring chemical processes, and ensuring the quality of products. Understanding how a conductivity meter works is essential for obtaining accurate and reliable measurements.

One of the key factors that affect conductivity measurements is the temperature of the solution being tested. Temperature has a significant impact on the conductivity of a solution because it affects the mobility of ions in the solution. As the temperature increases, the ions move more quickly, leading to an increase in conductivity. Therefore, it is important to calibrate the conductivity meter at the correct temperature to ensure accurate measurements.

Another factor that can influence conductivity measurements is the concentration of ions in the solution. The more ions present in the solution, the higher the conductivity will be. This is because ions are the carriers of electric charge in a solution, and a higher concentration of ions means more charge carriers available to conduct electricity. It is important to consider the concentration of ions in the solution when interpreting conductivity measurements to avoid inaccuracies.

| CCT-5300 | |||||

| Constant | 10.00cm-1 | 1.000cm-1 | 0.100cm-1 | 0.010cm-1 | |

| Conductivity | (500~20,000) | (1.0~2,000) | (0.5~200) | (0.05~18.25) | |

| μS/cm | μS/cm | μS/cm | MΩ·cm | ||

| TDS | (250~10,000) | (0.5~1,000) | (0.25~100) | —— | |

| ppm | ppm | ppm | |||

| Medium Temp. | (0~50)℃(Temp. Compensation : NTC10K) | ||||

| Accuracy | Conductivity: 1.5%(FS) | ||||

| Resistivity: 2.0%(FS) | |||||

| TDS: 1.5%(FS) | |||||

| Temp.:±0.5℃ | |||||

| Temperature compensation | (0~50)℃ with 25℃ as Standard | ||||

| Analog Output | Single isolated(4~20)mA,instrument/transmitter for selection | ||||

| Control Output | SPDT relay, Load capacity : AC 230V/50A(Max) | ||||

| Power Supply | CCT-5300E : DC24V | CCT-5320E : AC 220V±15% | |||

| Working Environment | Temp. (0~50)℃;Relative Humidity ≤85%RH(none condensation) | ||||

| Storage Environment | Temp.(-20~60)℃; Relative Humidity ≤85%RH(none condensation) | ||||

| Dimension | 96mm×96mm×105mm (H×W×D) | ||||

| Hole Size | 91mm×91mm (H×W) | ||||

| Installation | Panel mounted, fast installation | ||||

The type of ions present in the solution can also affect conductivity measurements. Different ions have different mobilities in a solution, which can impact the overall conductivity. For example, monovalent ions such as sodium and potassium have higher mobilities compared to divalent ions like calcium and magnesium. Therefore, a solution containing monovalent ions will have higher conductivity than a solution with divalent ions, even if they have the same concentration. Understanding the types of ions present in the solution is crucial for interpreting conductivity measurements accurately.

The conductivity of a solution can also be influenced by the presence of impurities or contaminants. Impurities can interfere with the movement of ions in the solution, leading to inaccurate conductivity measurements. It is important to ensure that the solution being tested is free from impurities to obtain reliable conductivity readings. Regular calibration and maintenance of the conductivity meter can help minimize the impact of impurities on measurements.

The conductivity meter itself can also affect the accuracy of conductivity measurements. Factors such as electrode material, electrode spacing, and calibration procedures can all impact the performance of the conductivity meter. It is important to use a high-quality conductivity meter and follow proper calibration procedures to ensure accurate and reliable measurements.

In conclusion, there are several factors that can affect conductivity measurements, including temperature, ion concentration, ion type, impurities, and the conductivity meter itself. Understanding these factors is essential for obtaining accurate and reliable conductivity measurements. By considering these factors and taking appropriate measures to minimize their impact, users can ensure that their conductivity measurements are accurate and meaningful. Conductivity meters play a crucial role in various industries, and understanding how they work is essential for obtaining reliable data.