Fixing Zone Valves: Simple Solutions for Efficient Heating

Troubleshooting Common Issues with Zone Valves

Zone valves are an essential component of a heating system that allows for the control of different areas or zones within a building. However, like any mechanical device, zone valves can experience issues that require troubleshooting and fixing. In this article, we will explore some common problems that can arise with zone valves and provide step-by-step instructions on how to fix them.

One of the most common issues with zone valves is a failure to open or close properly. This can result in uneven heating or cooling throughout the building. If you notice that a zone valve is not opening or closing as it should, the first step is to check the power supply. Ensure that the valve is receiving power by checking the circuit breaker or fuse. If the power supply is intact, the next step is to inspect the valve itself.

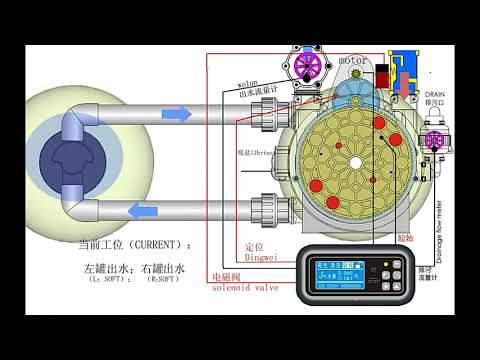

Start by removing the cover of the zone valve. Inside, you will find a motor and a valve body. Check for any obstructions or debris that may be preventing the valve from opening or closing. Clean the valve body thoroughly, removing any dirt or debris that may have accumulated. Once the valve body is clean, test the motor by manually turning the valve stem. If the motor does not respond or is sluggish, it may need to be replaced.

| Model | MSD2 | MSD4 | MSD4-B | MSD10 | ASD2 -LCD/LED | ASD4-LCD/LED | ASD10-LED |

| Working Position | Service->Back wash->Brine and slow rinse->Fast rinse->Refill->Service | ||||||

| Regeneration mode | Manual | Automatic | |||||

| Inlet | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1/2”, 3/4”, 1” | 2” |

| Outlet | 3/4” | 1” | 1” | 2” | 1/2”, 3/4”, 1” | 1/2”, 3/4”, 1” | 2” |

| Drain | 1/2” | 1/2” | 1/2” | 1” | 1/2” | 1/2” | 1” |

| Base | 2-1/2” | 2-1/2” | 2-1/2” | 4” | 2-1/2” | 2-1/2” | 4” |

| Riser pipe | 1.05”OD | 1.05”OD | 1.05”OD | 1.5”D-GB | 1.05”OD | 1.05”OD | 1.5”D-GB |

| Water Capacity | 2m3/h | 4m3/h | 4m3/h | 10m3/h | 2m3/h | 4m3/h | 10m3/h |

| Working Pressure | 0.15-0.6MPa | ||||||

| Working Temperature | 5-50°C | ||||||

| Power Supply | No Need Power | AC100-240V/50-60Hz DC12V-1.5A | |||||

Another common issue with zone valves is a leaking valve body. This can result in water leakage and potential damage to the surrounding area. To fix a leaking valve body, start by shutting off the water supply to the valve. Next, drain any remaining water from the system by opening a drain valve or using a bucket. Once the water is drained, remove the valve body from the system.

Inspect the valve body for any cracks or damage. If you find any, the valve body will need to be replaced. If the valve body is intact, check the gasket or O-ring for any signs of wear or damage. Replace the gasket or O-ring if necessary. Before reinstalling the valve body, clean the mating surfaces thoroughly to ensure a proper seal. Once the valve body is reinstalled, turn on the water supply and check for any leaks.

In some cases, zone valves may become stuck in the open or closed position. This can be caused by a faulty motor or a buildup of sediment within the valve body. To fix a stuck zone valve, start by removing the cover and inspecting the valve body. Clean the valve body thoroughly, removing any sediment or debris that may be causing the valve to stick. If the valve still does not move freely, the motor may need to be replaced.

In conclusion, troubleshooting and fixing common issues with zone valves is a relatively straightforward process. By following these step-by-step instructions, you can ensure that your zone valves are functioning properly and providing efficient heating or cooling to your building. Remember to always exercise caution when working with electrical components and consult a professional if you are unsure about any aspect of the repair process.