Table of Contents

How to Lap LS Valves for Maximum Performance: A Step-by-Step Guide

Lapping LS valves is a great way to maximize performance and ensure that your engine is running at its best. Here’s a step-by-step guide to help you get the job done right.

1. Gather the necessary supplies. You’ll need a valve lapping tool, valve lapping compound, and a clean rag.

2. Remove the valve cover and inspect the valves. Make sure they are all in good condition and free of any debris.

3. Apply a small amount of lapping compound to the valve face.

4. Insert the lapping tool into the valve guide and rotate it back and forth. This will help to evenly distribute the lapping compound.

5. Continue to rotate the lapping tool until the valve face is smooth and free of any imperfections.

6. Remove the lapping tool and wipe off any excess lapping compound with a clean rag.

7. Repeat steps 3-6 for each valve.

8. Reinstall the valve cover and start the engine to ensure that the valves are properly lapped.

Following these steps will help you get the most out of your LS engine. With a little bit of time and effort, you can ensure that your engine is running at its peak performance.

The Benefits of Lapping LS Valves and How to Do It Right

Lapping LS valves is a great way to ensure that your engine is running at its best. It’s a relatively simple process that can make a big difference in the performance of your engine. Here’s a look at the benefits of lapping LS valves and how to do it right.

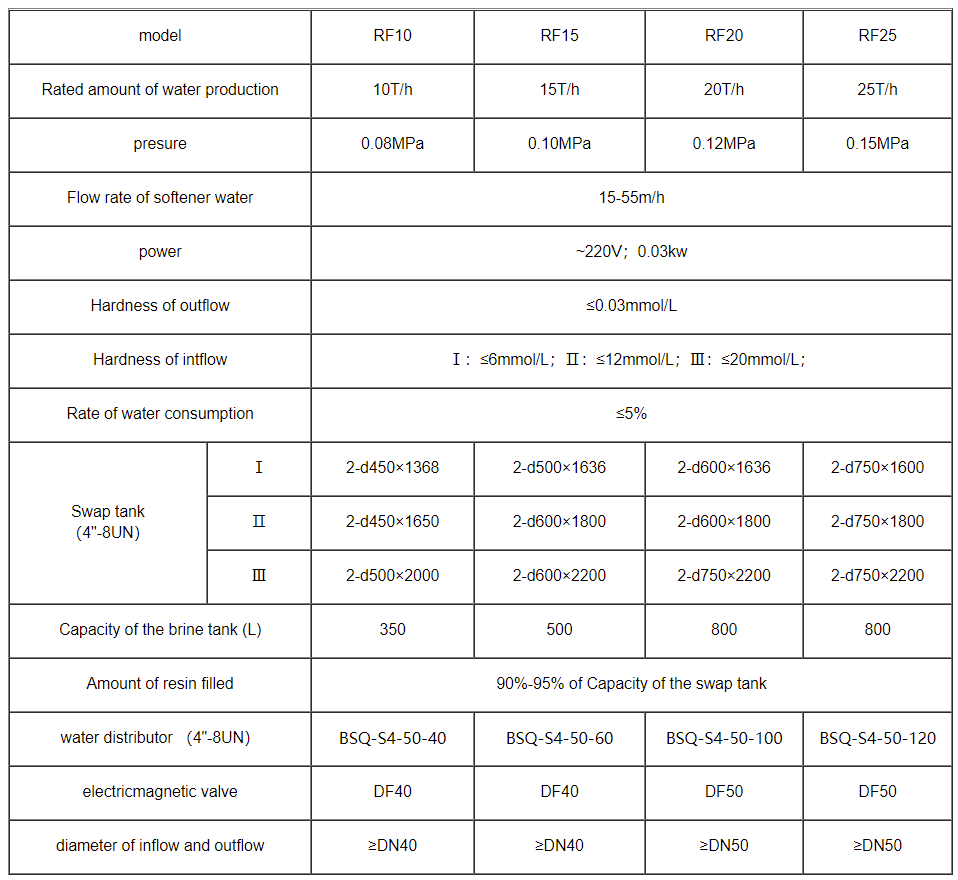

| Model | Valve Material | Inlet/Outlet | Continuous (0.1Mpa drop) | Peak (0.175Mpa drop) | Cv** | Maximum Backwash (0.175Mpa drop) | Distributor Pilot | Drain Line | Brine Line | Mounting Base | Height (from top of the tank) |

| CM28 | Unleaded brass | 1-1/2″ | 11.5m³/h | 15m³/h | 13.2 | 49gpm | 1.5″I.D. | 1″(male) | 1/2″, (3/8″) | 4″-8UN | 6-1/2″ |

The main benefit of lapping LS valves is that it helps to ensure a proper seal between the valve and the seat. This helps to reduce the amount of air and fuel that can escape, which can improve the performance of your engine. It also helps to reduce the amount of wear and tear on the valve and seat, which can extend the life of your engine.

When it comes to lapping LS valves, it’s important to use the right tools and techniques. You’ll need a valve lapping tool, which is a special tool designed to fit the valve stem. You’ll also need some lapping compound, which is a special abrasive paste that helps to create a smooth surface on the valve and seat.

To begin the lapping process, you’ll need to remove the valve from the engine and clean it thoroughly. Once it’s clean, you’ll need to apply a thin layer of lapping compound to the valve and seat. Then, you’ll need to use the lapping tool to rotate the valve back and forth in a circular motion. This helps to create a smooth surface on the valve and seat.

Once you’ve finished lapping the valve, you’ll need to clean off any excess lapping compound and then reinstall the valve in the engine. Make sure to check the valve for any signs of wear or damage before reinstalling it.

Lapping LS valves is a great way to ensure that your engine is running at its best. It’s a relatively simple process that can make a big difference in the performance of your engine. Just make sure to use the right tools and techniques and you’ll be sure to get the best results.