**1. DIY Guide: Creating the Best Plastic Quick-Disconnect Hose Coupling on a Budget**

Creating a high-quality plastic quick-disconnect hose coupling on a budget is a practical and cost-effective approach for anyone looking to assemble an efficient water or air distribution system. With the right tools and materials, it’s possible to construct a durable and reliable coupling that meets your specific needs without breaking the bank. In this DIY guide, we’ll explore the step-by-step process of creating the best plastic quick-disconnect hose coupling at the lowest cost possible.

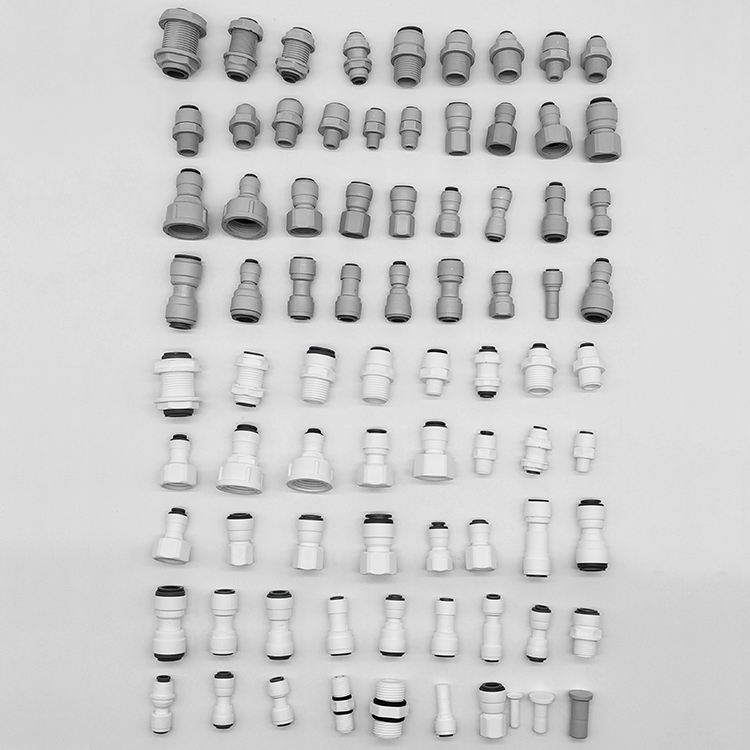

To begin the process, it’s essential to gather all the necessary materials and tools. You’ll need high-quality plastic connectors, such as barbed or push-to-connect fittings, that are compatible with your hose diameter. Additionally, you’ll require a sharp utility knife, a heat gun or hair dryer, and a suitable adhesive that bonds well with plastic materials. It’s crucial to invest in high-quality materials to ensure the longevity and effectiveness of your quick-disconnect hose coupling.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/40 |

The first step in creating the coupling is to cut the hose to the desired length using a sharp utility knife. It’s important to make a clean, straight cut to ensure a proper seal with the plastic connectors. Once the hose is cut to size, carefully insert the barbed or push-to-connect fittings into each end of the hose. Ensure that the fittings are securely in place to prevent any leakage or disconnection during use.

Next, use a heat gun or hair dryer to heat the end of the hose and the plastic connectors. Heating the materials will soften the plastic, allowing for a tighter and more secure fit. Be cautious not to overheat the plastic, as this can cause damage or distortion. Once the plastic is sufficiently heated, firmly press the connectors into the hose ends, creating a strong bond as the plastic cools and solidifies.

After the connectors are firmly in place, apply a suitable plastic adhesive to the junction between the hose and the connectors. This additional step reinforces the connection, providing extra security and preventing any potential leaks. It’s important to use an adhesive specifically designed for plastic materials to ensure a strong and durable bond.

Once the adhesive has set, test the quick-disconnect hose coupling to ensure its functionality and integrity. Connect the coupling to the corresponding male and female fittings, and test for any signs of leakage or instability. It’s crucial to verify the coupling’s effectiveness before implementing it into your water or air distribution system.

In conclusion, creating the best plastic quick-disconnect hose coupling on a budget is achievable with the right materials and a methodical approach. By carefully selecting high-quality plastic connectors and utilizing the appropriate tools and techniques, it’s possible to construct a durable and reliable coupling without incurring excessive