Select the Right Type of plastic quick coupling Valve:

plastic quick coupling valves are versatile components used in various industries for fluid handling and control applications. Selecting the right type of plastic quick coupling valve is crucial to ensure optimal performance and compatibility with specific requirements. When choosing a plastic quick coupling valve, several factors need to be considered, including the type of fluid, operating pressure, temperature, and environmental conditions. This article aims to provide a comprehensive guide on how to select the right type of plastic quick coupling valve for your specific application.

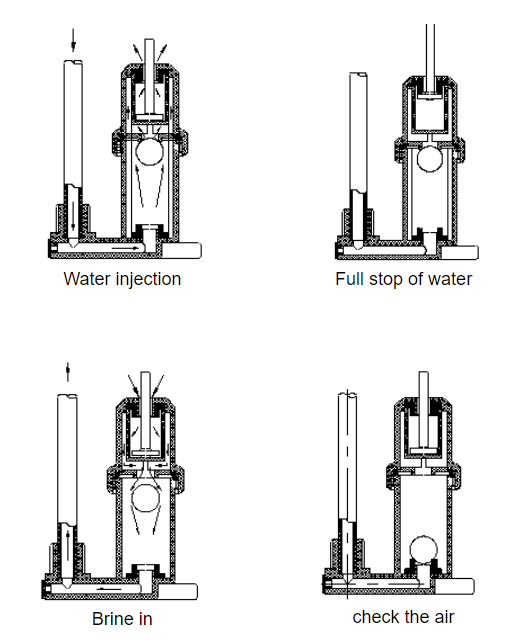

The first step in selecting a plastic quick coupling valve is to identify the type of fluid that will flow through the system. Different plastics are compatible with specific fluids, so it is essential to choose a material that is chemically resistant and suitable for the intended application. For example, polypropylene quick coupling valves are often used for water and chemical applications, while acetal quick coupling valves are suitable for air and gas handling.

In addition to fluid compatibility, the operating pressure and temperature of the system are critical factors to consider when choosing a plastic quick coupling valve. It is important to select a valve that can withstand the maximum pressure and temperature conditions to which it will be subjected. High-performance plastics such as PEEK and PVDF are suitable for applications requiring high temperature and pressure resistance, while polypropylene and nylon are more commonly used for lower pressure and temperature environments.

Furthermore, environmental conditions such as exposure to UV radiation, harsh chemicals, or abrasive materials should be taken into account when selecting a plastic quick coupling valve. Some plastics are specifically formulated to resist UV degradation and chemical attack, making them ideal for outdoor or corrosive environments. Understanding the environmental factors that the valve will be exposed to is essential in choosing a material that will ensure long-term durability and performance.

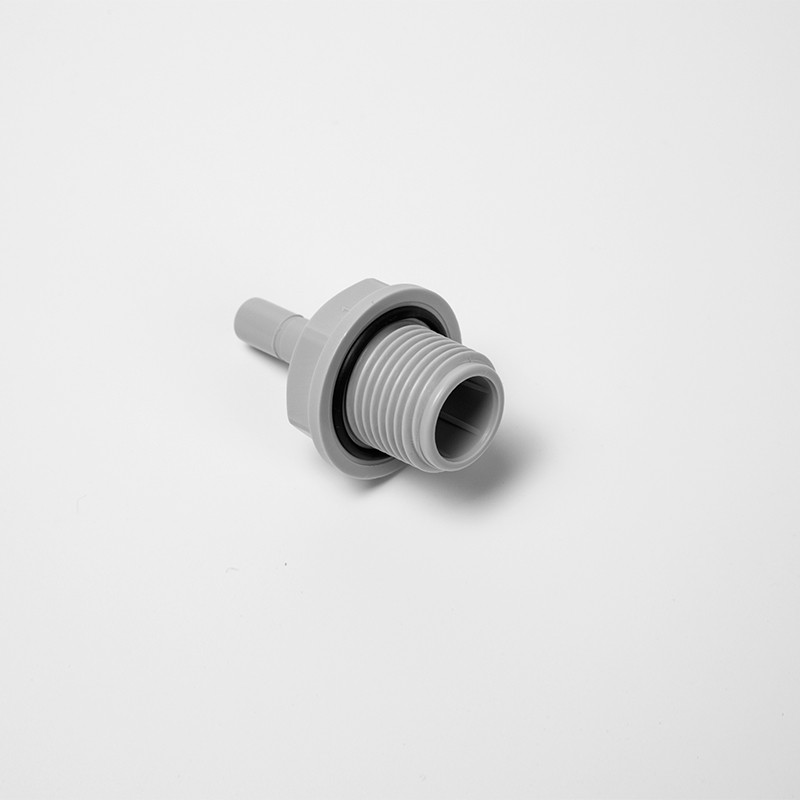

Another crucial consideration when selecting a plastic quick coupling valve is the connection type and size. There are various connection options available, including barbed, threaded, and push-to-connect fittings. It is important to choose a valve with the appropriate connection type that is compatible with the existing system components and can ensure a secure and leak-free connection.

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/12 |

Moreover, the ease of use and maintenance of the plastic quick coupling valve should also be taken into consideration. Some valves are designed for quick and easy connection and disconnection, while others may require additional tools or procedures for installation and maintenance. Selecting a valve with user-friendly features can improve operational efficiency and reduce downtime during maintenance and system reconfiguration.

In conclusion, selecting the right type of plastic quick coupling valve is essential to ensure optimal performance and compatibility with specific application requirements. By considering factors such as fluid compatibility, operating pressure and temperature, environmental conditions, connection type, and ease of use