Table of Contents

Benefits of Using Flow Sensors in Industrial Applications

Flow sensors are essential components in various industrial applications, providing accurate measurements of liquid or gas flow rates. The Flow Sensor 301 is a cutting-edge device that offers numerous benefits to industries looking to optimize their processes and improve efficiency.

One of the key advantages of using flow sensors in industrial applications is their ability to provide real-time data on flow rates. This information is crucial for monitoring and controlling the flow of liquids or gases in a system, ensuring that processes run smoothly and efficiently. The Flow Sensor 301 excels in this regard, offering high accuracy and reliability in measuring flow rates, allowing for precise control of industrial processes.

In addition to real-time data monitoring, flow sensors also play a crucial role in detecting any abnormalities or irregularities in flow rates. The Flow Sensor 301 is equipped with advanced technology that can quickly identify any deviations from the set flow parameters, alerting operators to potential issues before they escalate. This early detection capability can help prevent costly downtime and equipment damage, ultimately saving time and money for industrial operations.

Another significant benefit of using flow sensors like the Flow Sensor 301 is their versatility and adaptability to different industrial environments. These sensors can be easily integrated into existing systems, providing seamless compatibility with a wide range of equipment and machinery. Whether it’s monitoring flow rates in a chemical processing plant or controlling the flow of water in a cooling system, the Flow Sensor 301 can be customized to meet the specific needs of any industrial application.

Furthermore, flow sensors offer improved efficiency and productivity in industrial processes. By accurately measuring flow rates and providing real-time data, these sensors help optimize the use of resources and minimize waste. The Flow Sensor 301, with its high precision and reliability, can help industries streamline their operations, reduce energy consumption, and enhance overall productivity.

In addition to efficiency and productivity gains, flow sensors also contribute to improved safety in industrial settings. The Flow Sensor 301 is designed with robust materials and advanced technology to withstand harsh operating conditions and ensure reliable performance. By monitoring flow rates and detecting any anomalies, these sensors help prevent accidents and ensure the safety of workers and equipment in industrial environments.

Overall, the Flow Sensor 301 offers a wide range of benefits for industries looking to enhance their processes and improve efficiency. From real-time data monitoring to early anomaly detection, this cutting-edge device provides the accuracy, reliability, and versatility needed to optimize industrial operations. By investing in flow sensors like the Flow Sensor 301, industries can achieve greater efficiency, productivity, and safety in their operations, ultimately leading to cost savings and improved performance.

How to Choose the Right Flow Sensor for Your Specific Needs

Flow sensors are essential devices used in a wide range of industries to measure the flow rate of liquids or gases. They play a crucial role in ensuring the efficiency and accuracy of various processes, such as monitoring water consumption in residential buildings, controlling the flow of chemicals in industrial applications, or measuring the flow of fuel in automotive systems. With so many different types of flow sensors available on the market, choosing the right one for your specific needs can be a daunting task. In this article, we will discuss the key factors to consider when selecting a flow sensor and provide some tips to help you make an informed decision.

One of the first things to consider when choosing a flow sensor is the type of fluid you will be measuring. Different flow sensors are designed to work with specific types of fluids, such as water, oil, gas, or chemicals. It is important to select a flow sensor that is compatible with the fluid you will be measuring to ensure accurate and reliable results. For example, a flow sensor designed for water may not be suitable for measuring the flow of corrosive chemicals, as it may degrade over time and provide inaccurate readings.

Another important factor to consider is the flow rate range of the sensor. Flow sensors are typically rated for a specific flow rate, which is the range of flow rates that the sensor can accurately measure. It is important to choose a flow sensor with a flow rate range that matches the expected flow rates in your application. Selecting a flow sensor with a flow rate range that is too narrow may result in inaccurate readings, while choosing a sensor with a flow rate range that is too wide may lead to reduced accuracy and sensitivity.

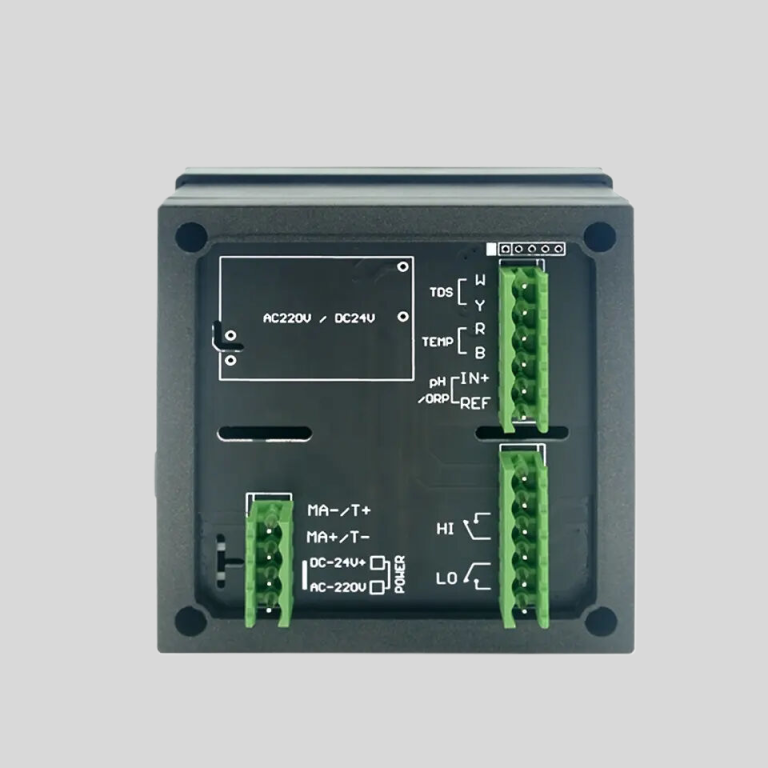

| model | pH/ORP-5500 series pH/ORP online transmitting controller | |

| Measurement range | pH | 0.00~14.00 |

| ORP | -2000mV~2000mV | |

| Temp. | ( 0.0~50.0)℃ (temperature compensation component:NTC10K) | |

| Resolution | pH | 0.01 |

| ORP | 1mV | |

| Temp. | 0.1℃ | |

| accuracy | pH | 0.1 |

| ORP | ±5mV(electronic unit) | |

| Temp. | ±0.5℃ | |

| Approximate input impedance | 3×1011Ω | |

| Buffer solution | pH value: 10.00;9.18;7.00;6.86;4.01;4.00 | |

| Temp. compensation range | (0~50)℃(with 25℃ as standard)Manual and automatic temperature compensation | |

| (4~20)mA | characteristics | Isolated,fully adjustable,reverible,instrument/transmitter for selection |

| Loop resistance | 500Ω(Max),DC 24V | |

| accuracy | ±0.1mA | |

| Control contact | Electrical contacts | Double relay SPST-NO,return model |

| Loop capacity | AC 220V/AC 110V 2A(Max);DC 24V 2A(Max) | |

| Power consumption | <3W | |

| Working environment | temperature | (0~50)℃ |

| humidity | ≤85%RH(none condensation) | |

| Storage environment | Temp.(-20-60) ℃;relative humidity:≤85%RH(none condensation | |

| Outline dimension | 96mm×96mm×105mm(H×W×D) | |

| Hole dimension | 91mm×91mm(H×W) | |

| installation | Panel mounted,fast installation | |

In addition to the type of fluid and flow rate range, it is also important to consider the accuracy and precision of the flow sensor. The accuracy of a flow sensor refers to how closely the measured flow rate matches the actual flow rate, while precision refers to the repeatability of the measurements. It is important to choose a flow sensor with high accuracy and precision to ensure reliable and consistent results. Some flow sensors may also offer additional features, such as temperature compensation or digital output, which can further enhance their performance and usability.

| Measuring Method | N,N-Diethyl-1,4-phenylenediamine (DPD) spectrophotometry | |||

| Model | CLA-7122 | CLA-7222 | CLA-7123 | CLA-7223 |

| Inlet water channel | Single channel | Dual channel | Single channel | Dual channel |

| Measurement range | Total Chlorine : (0.0 ~ 2.0)mg/L ,calculated as Cl2 ; | Total Chlorine : (0.5 ~10.0)mg/L ,calculated as Cl2 ; | ||

| pH:(0-14);temperature:(0-100)℃ | ||||

| Accuracy | Free chlorine: ±10% or 0.05mg/L (whichever is greater), calculated as Cl2; Total chlorine: ±10% or 0.05mg/L (whichever is greater), calculated as Cl2 | Free chlorine: ±10% or 0.25mg/L (whichever is greater), calculated as Cl2; Total chlorine: ±10% or 0.25mg/L (whichever is greater), calculated as Cl2 | ||

| pH:±0.1pH;Temp.:±0.5℃ | ||||

| Measurement cycle | Free Chlorine≤2.5min | |||

| Sampling interval | The interval (1~999) min can be set to any value | |||

| Maintenance cycle | Recommended once a month (see maintenance chapter) | |||

| Environmental | Ventilated and dry room without strong vibration; Suggested room temperature: (15 ~ 28)℃; relative humidity: ≤85% (no condensation). | |||

| requirements | ||||

| Sample water flow | (200-400) mL/min | |||

| inlet water pressure | (0.1-0.3) bar | |||

| Inlet water temperature range | (0-40)℃ | |||

| Power supply | AC (100-240)V; 50/60Hz | |||

| Consumption | 120W | |||

| Power connection | 3-core power cord with plug is connected to the mains socket with ground wire | |||

| Data output | RS232/RS485/(4~20)mA | |||

| Dimension size | H*W*D:(800*400*200)mm | |||

When selecting a flow sensor, it is also important to consider the installation requirements and environmental conditions of your application. Some flow sensors may require specific mounting configurations or installation procedures, while others may be more flexible and easy to install. It is important to choose a flow sensor that is compatible with your existing equipment and infrastructure to minimize installation costs and downtime. Additionally, it is important to consider the operating temperature, pressure, and humidity conditions of your application to ensure that the flow sensor can withstand the environmental conditions and provide accurate measurements.

In conclusion, choosing the right flow sensor for your specific needs requires careful consideration of several key factors, including the type of fluid, flow rate range, accuracy and precision, installation requirements, and environmental conditions. By taking the time to evaluate these factors and select a flow sensor that meets your requirements, you can ensure accurate and reliable flow measurements in your application. If you are unsure about which flow sensor to choose, it is recommended to consult with a flow sensor manufacturer or distributor for expert advice and guidance.