Table of Contents

Importance of conductivity meter in water Quality Testing

Conductivity meters are essential tools in water quality testing, providing valuable information about the purity and safety of water. Conductivity refers to the ability of a substance to conduct electricity, and in the case of water, it is a measure of the concentration of ions present in the water. These ions can come from various sources, including dissolved salts, minerals, and other contaminants.

One of the key reasons why conductivity meters are important in water quality testing is that they can help identify the presence of contaminants in water. High levels of conductivity can indicate the presence of dissolved solids, such as salts, metals, and other pollutants. By measuring conductivity, water quality professionals can quickly assess the overall purity of a water sample and determine if further testing is needed to identify specific contaminants.

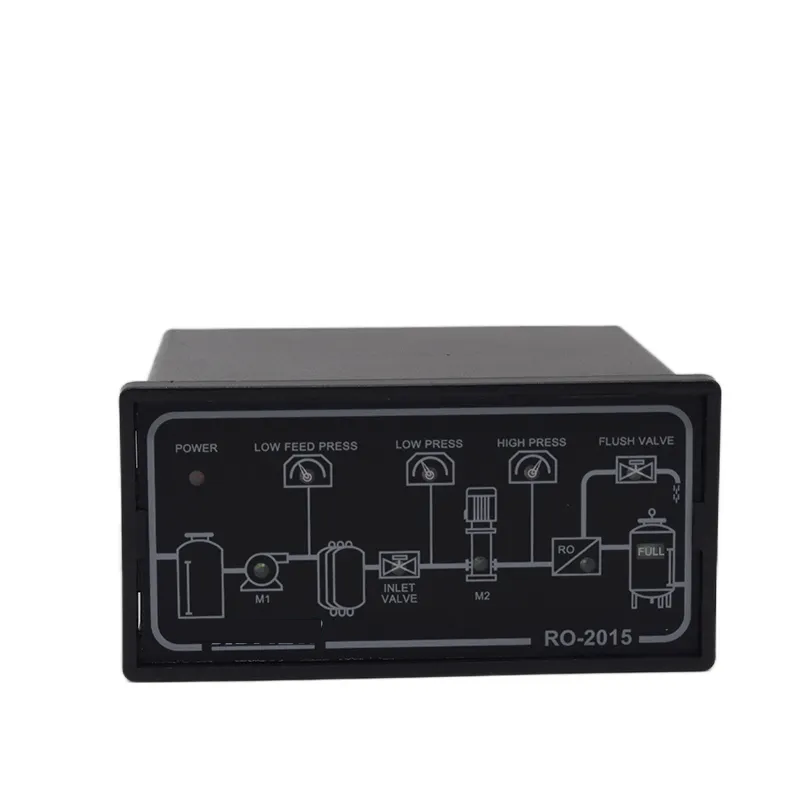

Conductivity meters are also valuable tools for monitoring water treatment processes. Water treatment plants use a variety of methods to remove contaminants from water, such as filtration, chlorination, and reverse osmosis. By regularly measuring conductivity throughout the treatment process, operators can ensure that the treatment is effective in removing contaminants and producing safe drinking water.

In addition to monitoring water treatment processes, conductivity meters are also used in environmental monitoring and research. Scientists use conductivity measurements to study the impact of pollution on water bodies, track changes in water quality over time, and assess the effectiveness of conservation efforts. Conductivity data can provide valuable insights into the health of aquatic ecosystems and help guide efforts to protect and preserve water resources.

| Model | CL-810/9500 Residual Chlorine Controller |

| Range | FAC/HOCL:0-10 mg/L, ATC TEMP:0-50℃ |

| Accuracy | FAC/HOCL:0.1 mg/L, ATC TEMP:0.1℃ |

| Oper. Temp. | 0~50℃ |

| Sensor | Constant Pressure Residual Chlorine Sensor |

| Waterproof Rate | IP65 |

| Communication | Optional RS485 |

| Output | 4-20mA output; High/Low limit double relay control |

| Power | CL-810:AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| CL-9500:AC 85V-265V±10% 50/60Hz | |

| Working Environment | Ambient temperature:0~50℃; |

| Relative humidity≤85% | |

| Dimensions | CL-810:96×96×100mm(H×W×L) |

| CL-9500:96×96×132mm(H×W×L) | |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

Conductivity meters are versatile instruments that can be used in a wide range of applications, from testing drinking water quality to monitoring industrial wastewater discharge. They are portable, easy to use, and provide quick and accurate results, making them indispensable tools for water quality professionals.

One of the key advantages of conductivity meters is their ability to provide real-time data on water quality. Unlike traditional water testing methods that require samples to be sent to a lab for analysis, conductivity meters can provide instant results in the field. This allows for faster decision-making and response to water quality issues, helping to protect public health and the environment.

Another important aspect of conductivity meters is their ability to detect changes in water quality over time. By regularly monitoring conductivity levels in a water body, researchers can track trends and identify potential sources of contamination. This information can be used to develop strategies for improving water quality, implementing pollution control measures, and protecting sensitive ecosystems.

In conclusion, conductivity meters play a crucial role in water quality testing by providing valuable information about the purity and safety of water. They are essential tools for identifying contaminants, monitoring treatment processes, and conducting environmental research. With their ability to provide real-time data and track changes in water quality over time, conductivity meters are indispensable instruments for ensuring the health and sustainability of our water resources.

How to Choose the Right conductivity meter for Your Needs

Conductivity meters are essential tools used in various industries to measure the ability of a solution to conduct electricity. This measurement is crucial in determining the purity and concentration of a solution, making conductivity meters a valuable asset in laboratories, water treatment plants, and manufacturing facilities. With the wide range of conductivity meters available on the market, choosing the right one for your specific needs can be a daunting task. In this article, we will discuss the meaning of conductivity meters and provide tips on how to choose the right one for your requirements.

Conductivity meters work on the principle that ions in a solution carry an electric charge, allowing the solution to conduct electricity. The conductivity of a solution is directly proportional to the concentration of ions present in the solution. Therefore, conductivity meters are used to measure the conductivity of a solution, which can then be correlated to the concentration of ions in the solution. This information is crucial in various applications, such as monitoring water quality, determining the purity of chemicals, and controlling the concentration of solutions in industrial processes.

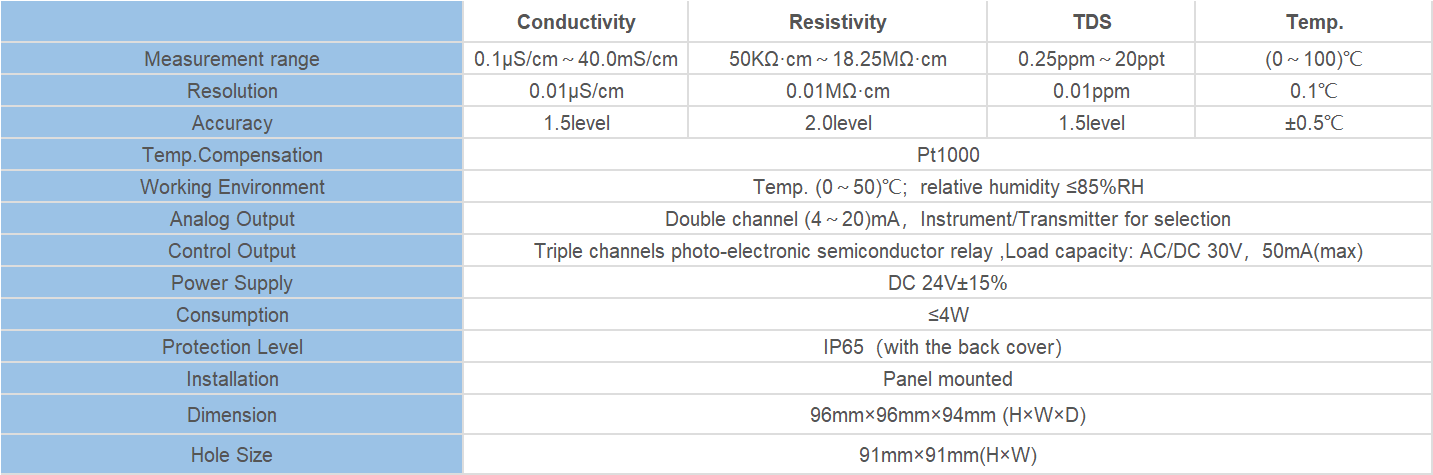

| Model | CCT-3300 Series Conductivity Online Controller |

| Constant | 0.01cm-1, 0.1 cm-1, 1.0cm-1, 10.0 cm-1 |

| Conductivity | (0.5~20)mS/cm,(0.5~2,000)uS/cm, (0.5~200)uS/cm, (0.05~18.25)MQ·cm |

| TDS | (250~10,000)ppm, (0.5~1,000)ppm, (0.25~100)ppm |

| Medium Temp. | (0~50)℃ |

| Resolution | Conductivity: 0.01uS/cm, TDS:0.01ppm, Temp.: 0.1℃ |

| Accuracy | Conductivity: 1.5%(FS), Resistivity:2.0%(FS), TDS: 1.5%(FS), Temp.: +/-0.5℃ |

| Temp. compensation | (0-50)°C (with 25℃ as Standard) |

| Cable length | ≤5m(MAX) |

| mA output | Isolated (4~20)mA, Instrument / Transmitter for selection |

| Control Output | relay contact: ON/OFF, Load capacity: AC 230V/5A(Max) |

| Working Environment | Temp.(0~50)℃;Relative Humidity ≤85%RH (none condensation) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | CCT-3300:DC 24V; CCT-3310: AC 110V; CCT-3320: AC 220V |

| Dimension | 48mmx96mmx80mm(HxWxD) |

| Hole Size | 44mmx92mm(HxW) |

| Installation | Panel mounted, fast installation |

When choosing a conductivity meter, there are several factors to consider to ensure that you select the right instrument for your needs. The first factor to consider is the range of conductivity that the meter can measure. Different applications require different ranges of conductivity measurement, so it is essential to choose a meter that can accurately measure the conductivity of your solution. Some meters have a wide range of conductivity measurement, while others are more specialized for specific applications.

Another important factor to consider is the accuracy and precision of the conductivity meter. The accuracy of a meter refers to how close the measured value is to the true value, while precision refers to the consistency of the measurements. It is crucial to choose a meter that provides accurate and precise measurements to ensure the reliability of your results. Some meters come with built-in calibration features to ensure accurate measurements, while others may require external calibration.

The type of solution being measured is also an essential factor to consider when choosing a conductivity meter. Some solutions may be corrosive or abrasive, requiring a meter that is resistant to these conditions. In such cases, it is essential to choose a meter with a durable construction and materials that can withstand harsh environments. Additionally, some solutions may have high conductivity levels, requiring a meter with a high range of measurement to accurately measure the conductivity.

The ease of use and maintenance of the conductivity meter is another factor to consider when making your selection. Some meters may come with advanced features and functionalities that require training to operate effectively, while others may be more straightforward to use. It is essential to choose a meter that is user-friendly and easy to maintain to ensure that it can be used efficiently in your application.

In conclusion, conductivity meters are valuable tools used in various industries to measure the conductivity of solutions accurately. When choosing a conductivity meter, it is essential to consider factors such as the range of measurement, accuracy, precision, durability, and ease of use. By carefully evaluating these factors, you can select the right conductivity meter for your specific needs and ensure reliable and accurate measurements in your application.