Table of Contents

Features and Benefits of the Horiba F-52 Gas Analyzer

The Horiba F-52 Gas Analyzer is a cutting-edge instrument that offers a wide range of features and benefits for users in various industries. This advanced device is designed to provide accurate and reliable measurements of gas concentrations in a variety of applications, making it an essential tool for quality control, environmental monitoring, and research purposes.

One of the key features of the Horiba F-52 Gas Analyzer is its high level of accuracy. This instrument is equipped with state-of-the-art sensors and detectors that are capable of detecting even the smallest concentrations of gases with precision. This level of accuracy is essential for ensuring the quality and safety of products in industries such as pharmaceuticals, food and beverage, and environmental monitoring.

In addition to its accuracy, the Horiba F-52 Gas Analyzer also offers a wide range of measurement capabilities. This versatile instrument is capable of measuring a variety of gases, including carbon dioxide, oxygen, nitrogen, and many others. This flexibility makes it an ideal choice for users who need to monitor multiple gases simultaneously or who work in industries where a wide range of gases are present.

Another key benefit of the Horiba F-52 Gas Analyzer is its ease of use. This instrument is designed with the user in mind, featuring a simple and intuitive interface that makes it easy to operate. The device also comes with a range of pre-programmed settings and calibration options, allowing users to quickly and easily set up the instrument for their specific needs.

The Horiba F-52 Gas Analyzer is also highly portable, making it ideal for use in a variety of settings. Whether you need to take measurements in a laboratory, a manufacturing facility, or out in the field, this instrument is lightweight and easy to transport. This portability makes it a versatile tool that can be used in a wide range of applications.

In addition to its accuracy, versatility, and ease of use, the Horiba F-52 Gas Analyzer also offers a range of advanced features that set it apart from other gas analyzers on the market. For example, this instrument is equipped with advanced data logging capabilities, allowing users to store and analyze large amounts of data over time. This feature is essential for users who need to track changes in gas concentrations over extended periods.

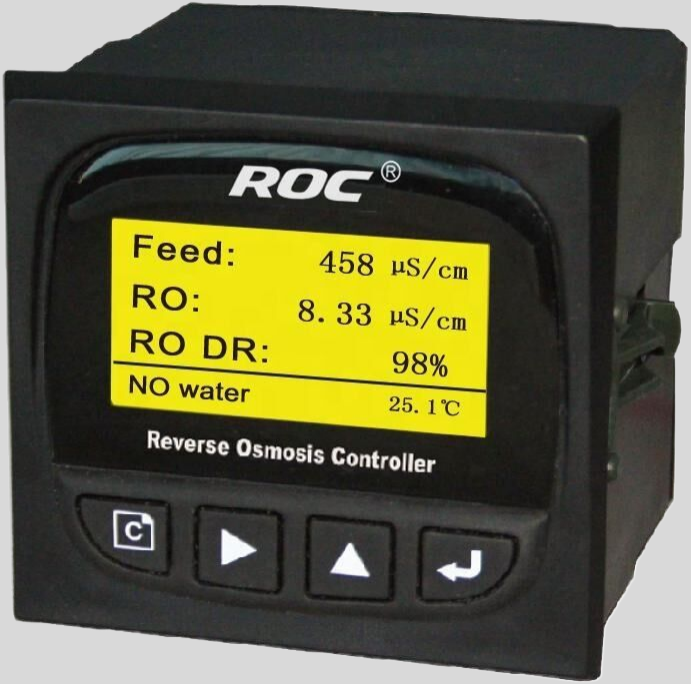

| Controller type | ROC-7000 Single-stage/Double-stage Reverse osmosis control integrated system | |||||

| Cell constant | 0.1cm-1 | 1.0 cm-1 | 10.0cm-1 | |||

| Conductivity measurement parameters | Raw water conductivity | (0~2000) | (0~20000) | |||

| Primary conductivity | (0~200) | (0~2000) | ||||

| Secondary conductivity | (0~200) | (0~2000) | ||||

| Temperature compensation | Automatic compensation on the basis of 25 ℃ ,compensation range(0~50)℃ | |||||

| Accuracy | Matched precision:1.5 level | |||||

| Flow measurement range | Instantaneous flow | (0~999)m3/h | ||||

| Accumulative flow | (0~9999999)m3 | |||||

| pH | Measurement range | 2-12 | ||||

| measurement parameters | Accuracy | ±0.1pH | ||||

| Temperature compensation | Automatic compensation on the basis of 25 ℃ ,compensation range(0~50)℃ | |||||

| DI acquisition | Input signal | Low pressure switch of Tap water,high level of pure water tank, low level of pure water tank, low pressure switch before the pump, high pressure switch after the primary booster pump,high level of secondary pure water tank, low level of secondary pure water tank,high pressure switch after the secondary booster pump | ||||

| Signal Type | Passive switch contact | |||||

| DO Control | Control output | Inlet valve, primary flush valve, primary drain valve, antiscalant pump, raw water pump, primary booster pump, secondary booster pump, secondary flush valve, secondary drain valve, pH adjustment metering pump. | ||||

| Electrical contact | Relay(ON/OFF) | |||||

| Load capacity | 3A(AC 250V)~ 3A(DC 30V) | |||||

| Display screen | Screen color:TFT;resolution:800×480 | |||||

| Working power | Working power | DC 24V±4V | ||||

| Power consumption | ≤6.0W | |||||

| Working environment | Temperature:(0~50)℃;Relative humidity:≤85%RH(non condensation) | |||||

| Storage environment | Temperature:(-20~60)℃;Relative humidity:≤85%RH(non condensation) | |||||

| Installation | Panel mounted | Hole(Length×Width,192mm×137mm) | ||||

Furthermore, the Horiba F-52 Gas Analyzer is also equipped with advanced connectivity options, allowing users to easily transfer data to a computer or other devices for further analysis. This feature is essential for users who need to share data with colleagues or integrate their measurements into larger data sets.

Overall, the Horiba F-52 Gas Analyzer is a powerful and versatile instrument that offers a wide range of features and benefits for users in various industries. From its high level of accuracy to its ease of use and advanced features, this instrument is an essential tool for anyone who needs to measure gas concentrations with precision and reliability.

How to Properly Maintain and Calibrate the Horiba F-52 Gas Analyzer

The Horiba F-52 gas analyzer is a powerful tool used in a variety of industries to measure and analyze gas concentrations. To ensure accurate and reliable results, it is essential to properly maintain and calibrate the analyzer on a regular basis. In this article, we will discuss the importance of maintaining and calibrating the Horiba F-52 gas analyzer, as well as provide some tips on how to do so effectively.

Regular maintenance of the Horiba F-52 gas analyzer is crucial to ensure its proper functioning and accuracy. Dust, dirt, and other contaminants can build up on the analyzer over time, affecting its performance and reliability. To prevent this, it is important to clean the analyzer regularly using a soft, dry cloth. Avoid using harsh chemicals or abrasive materials, as these can damage the sensitive components of the analyzer.

In addition to cleaning, it is also important to check the analyzer for any signs of wear or damage. Inspect the cables, connectors, and sensors for any visible damage, and replace any worn or damaged parts as needed. Regularly inspecting the analyzer can help prevent potential issues and ensure that it continues to provide accurate results.

Calibrating the Horiba F-52 gas analyzer is another important aspect of maintenance. Calibration is the process of adjusting the analyzer to ensure that it provides accurate and reliable measurements. Without proper calibration, the analyzer may produce inaccurate results, leading to errors in data analysis and decision-making.

There are several methods for calibrating the Horiba F-52 gas analyzer, depending on the specific requirements of your industry and the gases being measured. One common method is to use calibration gases with known concentrations to adjust the analyzer’s settings. These calibration gases can be purchased from specialized suppliers and should be used according to the manufacturer’s instructions.

It is recommended to calibrate the Horiba F-52 gas analyzer regularly, ideally at least once a month or as recommended by the manufacturer. This will help ensure that the analyzer remains accurate and reliable, providing consistent results over time. Keep a record of all calibration procedures and results for future reference and quality control purposes.

| Model | EC-1800 online conductivity controller |

| Range | 0-2000/4000uS/cm 0-20/200mS/cm |

| 0-1000/2000PPM | |

| Accuracy | 1.5%, 2%, 3%(FS) |

| Temp. Comp. | Automatic temperature compensation based on 25℃ |

| Oper. Temp. | Normal 0~50℃; High temp 0~120℃ |

| Sensor | C=0.1/1.0/10.0cm-1 |

| Display | 128*64 LCD Screen |

| Communication | 4-20mA output/2-10V/1-5V/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×100mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

In conclusion, proper maintenance and calibration of the Horiba F-52 gas analyzer are essential to ensure its accuracy and reliability. By regularly cleaning and inspecting the analyzer, as well as calibrating it according to the manufacturer’s instructions, you can help prolong its lifespan and ensure that it continues to provide accurate measurements. Remember to keep detailed records of all maintenance and calibration procedures for quality control purposes. With proper care and attention, your Horiba F-52 gas analyzer will continue to be a valuable tool in your industry for years to come.