How to Revive a Dried Out ph meter Electrode

A ph meter is an essential tool for measuring the acidity or alkalinity of a solution. It consists of a probe with a glass electrode that detects the hydrogen ion concentration in the solution. However, if the electrode dries out, it can affect the accuracy of the pH readings. In this article, we will discuss how to revive a dried out ph meter electrode to ensure accurate measurements.

When a ph meter electrode dries out, it can lead to a buildup of contaminants on the glass membrane, affecting its sensitivity and response time. This can result in inaccurate pH readings and potentially damage the electrode. To revive a dried out ph meter electrode, the first step is to rehydrate the glass membrane.

| FL-9900 High Precision Type Runner Flow Controller | ||

| Measuring range | Frequency | 0~2K Hz |

| Velocity of flow | 0.5~5 m/s | |

| Instantaneous flow | 0~2000 m³/h | |

| Cumulative flow | 0~9999 9999.999 m³ | |

| Applicable pipe diameter range | DN15~DN100;DN125~DN300 | |

| Resolution | 0.01 m³/h | |

| Refresh rate | 1s | |

| Accuracy class | Level 2.0 | |

| Repeatability | ±0.5% | |

| Sensor input | Radius:0~2K Hz | |

| Supply voltage:DC 24V(instrument internal supply) | ||

| The electronic unit automatically temperature compensates for errors | +0.5%FS; | |

| 4-20mA | Technical characteristics | Meter/transmitter dual mode (photoelectric isolation) |

| Loop resistance | 500Q(max),DC24V; | |

| Transmission accuracy | ±0.01mA | |

| Control port | Contact mode | Passive relay control output |

| Load capacity | Load current 5A (max) | |

| Function selection | Instantaneous flow upper/lower alarm | |

| Mains supply | Working voltage: DC24V 4V Power consumption :<; 3.OW | |

| Cable length | Factory configuration: 5m, can be agreed: (1~500) m | |

| Environmental requirement | Temperature: 0~50℃; Relative humidity: ≤85%RH | |

| Storage environment | Temperature: (-20~60) ℃; Humidity: 85%RH | |

| Overall dimension | 96×96×72mm(height × width × depth) | |

| Opening size | 92×92mm | |

| Installation mode | Disc mounted, fast fixed | |

| Sensor | Body material | Body: Engineering plastic PP; Bearing :Zr02 high temperature zirconia |

| Flow rate range | 0.5~5 m/s | |

| Withstand pressure | ≤0.6MPa | |

| Supply voltage | lDC 24V | |

| Output pulse amplitude| | Vp≥8V | |

| Normal pipe diameter | DN15~DN100;DN125~DN600 | |

| Medium characteristic | Single-phase medium(0~60℃) | |

| Installation mode | Direct line insertion | |

To rehydrate the glass membrane, you will need to soak the electrode in a storage solution or a buffer solution with a pH of around 4. This will help to remove any contaminants and rehydrate the glass membrane. It is important to ensure that the electrode is fully submerged in the solution and left to soak for at least 24 hours.

After soaking the electrode, you will need to calibrate the ph meter to ensure accurate readings. Calibration involves adjusting the ph meter to read the correct pH value of a buffer solution. This can be done using calibration solutions with known pH values. It is important to follow the manufacturer’s instructions for calibration to ensure accurate readings.

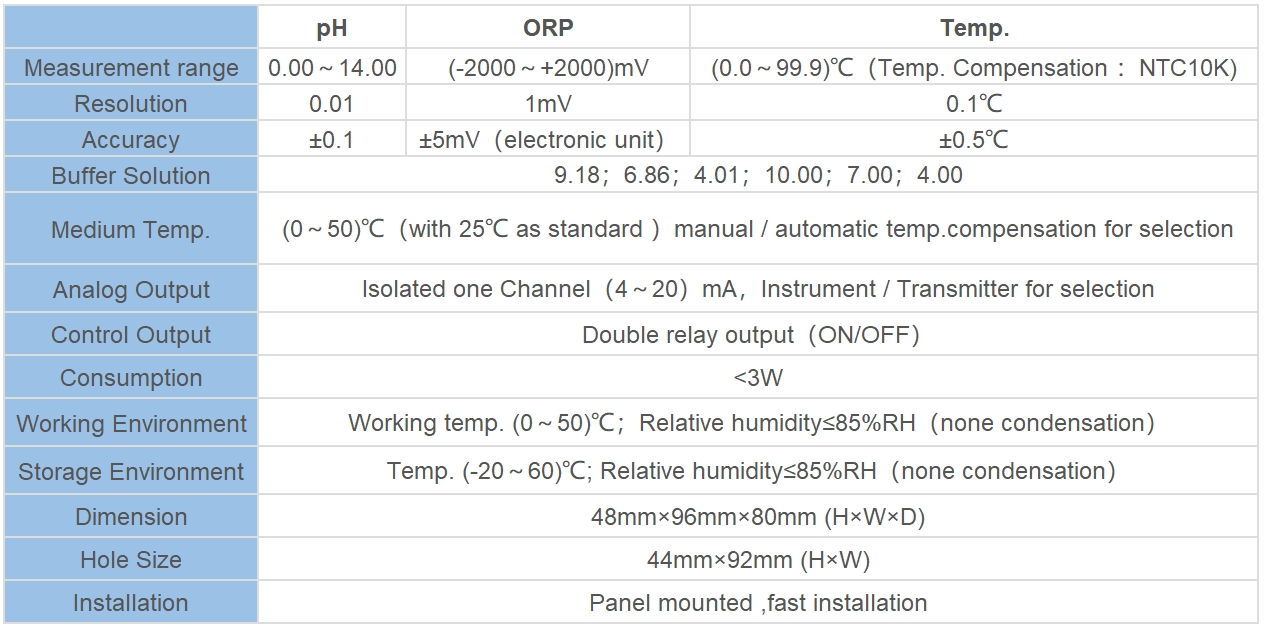

| Model | pH/ORP-5500 pH/ORP Online Meter |

| Range | pH:0.00~14.00 ; ORP: (-2000~+2000)mV; Temp.:(0.0~99.9)°C (Temp.Compensation: NTC10K) |

| Resolution | pH:0.01 ; ORP: 1mV; Temp.:0.1°C |

| Accuracy | pH:+/-0.1 ; ORP: +/-5mV(electronic unit); Temp.: +/-0.5°C |

| Temp. compensation | Range: (0~120)°C; element: Pt1000 |

| Buffer Solution | pH value 9.18; 6.86; 4.01; 10.00; 7.00; 4.00 |

| Medium Temp. | (0~50)°C (with 25°C as standard) manual/automatic temp. compensation for selection |

| Analog output | Isolated (4~20)mA, Instrument/Transmitter for selection |

| Control Output | Double relay output (ON/OFF); AC 240V/3A |

| Working Environment | Temp.(0~50)℃; relative humidity <95%RH (non-condensing) |

| Storage Environment | Temp.(-20~60)℃;Relative Humidity ≤85%RH (none condensation) |

| Power Supply | DC 24V; AC 110V; AC220V |

| Power consumption | <3W |

| Protection level | IP65 (with back cover) |

| Dimension | 96mmx96mmx105mm(HxWxD) |

| Hole Size | 91mmx91mm(HxW) |

In addition to rehydrating the glass membrane and calibrating the ph meter, it is important to properly store the electrode to prevent it from drying out in the future. The electrode should be stored in a storage solution or a buffer solution with a pH of around 4 when not in use. This will help to keep the glass membrane hydrated and maintain the accuracy of the pH readings.

It is also important to regularly clean the electrode to remove any contaminants that may affect its performance. Cleaning the electrode involves rinsing it with distilled water and wiping it with a soft cloth. It is important to avoid using harsh chemicals or abrasive materials that could damage the glass membrane.