Table of Contents

The Importance of Regular Calibration for ph meter Equipment

pH meters are essential tools used in various industries, including food and beverage, pharmaceuticals, environmental monitoring, and research laboratories. These devices measure the acidity or alkalinity of a solution by determining the concentration of hydrogen ions present. Accurate pH measurements are crucial for ensuring product quality, maintaining regulatory compliance, and conducting scientific research.

To ensure the accuracy and reliability of ph meter readings, regular calibration is necessary. Calibration is the process of adjusting the ph meter to a known standard to ensure that it provides accurate and consistent measurements. Over time, pH meters can drift out of calibration due to factors such as temperature fluctuations, electrode aging, and exposure to harsh chemicals. Regular calibration helps to correct these deviations and ensures that the ph meter continues to provide accurate readings.

| Measurement range | N,N-Diethyl-1,4-phenylenediamine (DPD) spectrophotometry | |||

| Model | CLA-7112 | CLA-7212 | CLA-7113 | CLA-7213 |

| Inlet channel | Single channel | Double channel | Single channel | Double channel |

| Measurement range | Free chlorine:(0.0-2.0)mg/L ,Calculated as Cl2; | Free chlorine:(0.5-10.0)mg/L ,Calculated as Cl2; | ||

| pH:(0-14);Temperature:(0-100)℃ | ||||

| Accuracy | Free chlorine:±10% or ±0.05mg/L(take the large value),Calculated as Cl2; | Free chlorine:±10% or±0.25mg/L(take the large value),Calculated as Cl2; | ||

| pH:±0.1pH;Temperature:±0.5℃ | ||||

| Measurement Period | ≤2.5min | |||

| Sampling interval | The interval (1~999) min can be set arbitrarily | |||

| Maintenance cycle | Recommended once a month (see maintenance chapter) | |||

| Environmental requirements | A ventilated and dry room without strong vibration;Recommended room temperature:(15~28)℃;Relative humidity:≤85%(No condensation) | |||

| Water sample flow | (200-400) mL/min | |||

| Inlet pressure | (0.1-0.3) bar | |||

| Inlet water temperature range | (0-40)℃ | |||

| Power supply | AC (100-240)V; 50/60Hz | |||

| Power | 120W | |||

| Power connection | The 3-core power cord with plug is connected to the mains socket with ground wire | |||

| Data output | RS232/RS485/(4~20)mA | |||

| Size | H*W*D:(800*400*200)mm | |||

There are two main types of calibration methods for pH meters: single-point calibration and multi-point calibration. Single-point calibration involves adjusting the ph meter to a single standard solution with a known pH value. This method is suitable for applications where only one pH value is of interest. Multi-point calibration, on the other hand, involves adjusting the ph meter to two or more standard solutions with different pH values. This method is more accurate and is recommended for applications where a wider range of pH values is being measured.

The frequency of calibration depends on the specific requirements of the application and the manufacturer’s recommendations. In general, pH meters should be calibrated at least once a day or before each use to ensure accurate measurements. However, in some critical applications, such as pharmaceutical manufacturing or environmental monitoring, more frequent calibration may be necessary.

In addition to regular calibration, proper maintenance of ph meter equipment is essential for ensuring accurate measurements. This includes cleaning the electrodes with a suitable cleaning solution, storing the ph meter properly when not in use, and replacing the electrodes as needed. Failure to maintain ph meter equipment can lead to inaccurate readings and compromise the quality of the results.

Calibration of ph meter equipment is typically performed using buffer solutions with known pH values. These solutions are available in various pH values, ranging from acidic (pH 4.01) to alkaline (pH 10.01). It is important to use fresh buffer solutions and follow the manufacturer’s instructions for calibration to ensure accurate results.

In conclusion, regular calibration of ph meter equipment is essential for ensuring accurate and reliable measurements. Calibration corrects for deviations in the ph meter caused by factors such as temperature fluctuations, electrode aging, and exposure to harsh chemicals. Proper maintenance of ph meter equipment is also crucial for ensuring accurate readings. By following the manufacturer’s recommendations for calibration and maintenance, users can ensure that their ph meter equipment continues to provide accurate measurements for their specific applications.

How to Properly Maintain and Store ph meter Equipment

Maintaining and properly storing ph meter equipment is essential for ensuring accurate and reliable measurements. pH meters are used in a variety of industries, including agriculture, food and beverage, water treatment, and pharmaceuticals, to name a few. These devices measure the acidity or alkalinity of a solution, providing valuable information for quality control and process optimization.

One of the most important aspects of maintaining ph meter equipment is regular calibration. Calibration ensures that the ph meter is providing accurate readings and is essential for obtaining reliable results. pH meters should be calibrated before each use, using calibration solutions of known pH values. This process should be done according to the manufacturer’s instructions to ensure accuracy.

In addition to calibration, regular cleaning of ph meter equipment is also crucial. Over time, dirt, dust, and other contaminants can build up on the electrodes of the ph meter, affecting its performance. To clean the electrodes, gently wipe them with a soft cloth or tissue soaked in a mild cleaning solution, such as a mixture of water and detergent. Avoid using abrasive materials or harsh chemicals, as these can damage the electrodes.

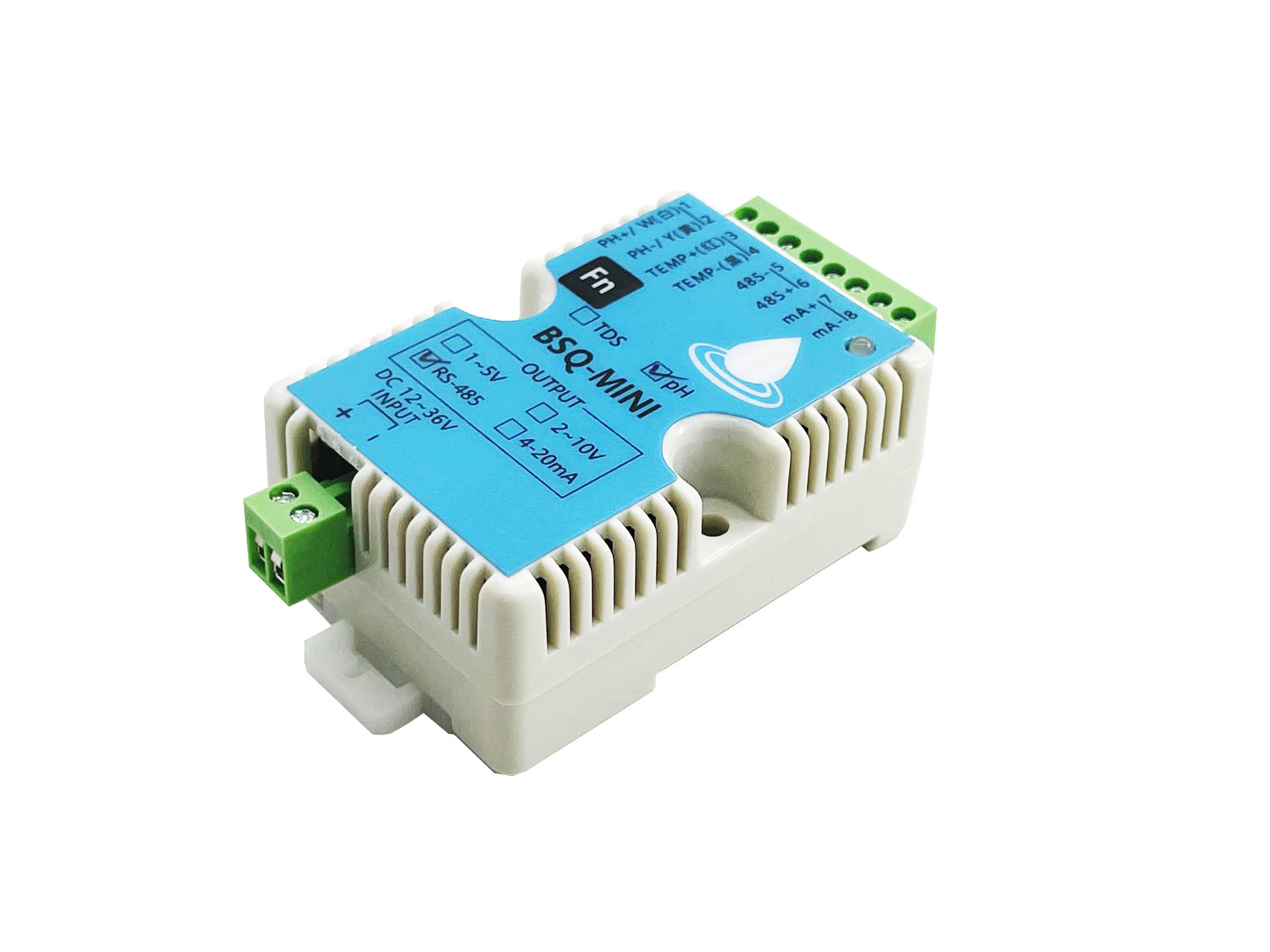

| POP-8300 free chlorine online analyzer | ||

| System Model | POP-8300 free chlorine online analyzer | |

| Measurement configuration | (HClO)free chlorine.. | |

| total free chlorine/(ClO2)/pH/Temperature | ||

| Free chlorine | (0.00-2.00)mg/L(ppm); (0.00-20.00)mg/L(ppm) | |

| Measurement | pH | 2.00-12.00 |

| range | Temperature | (0.0-99.9)℃ |

| Free chlorine | 0.01mg/L(ppm) | |

| Resolution | pH | 0.01 |

| Temperature | 0.1℃ | |

| Free chlorine | Indication error 10% | |

| Accuracy | pH | 0.1pH |

| Temperature | ±0.5℃ | |

| Sensor life | pH/free chlorine sensor | 12months(The service life is closely related to the measurement medium and maintenance frequency) |

| Communication interface | RS485 | MODBUS RTU communication protocol |

| Number of channels | Double channels | |

| (4-20)mA | Technical feature | Isolated, reversible, completely adjustable, instrument/transmitter dual mode |

| output | Channel configuration | Programmable point to Free chlorine, chlorine dioxide, Temperature, pH |

| Loop resistance | 400Ω(Max), DC 24V | |

| Transmission accuracy | ±0.1mA | |

| Number of channels | Double channels | |

| Contact mode | The first and second for photoelectric switch | |

| Control output | Load capacity | Load current 50mA(Max),AC/DC 30V |

| Control point | Programmable function(Free chlorine, chlorine dioxide, Temperature, pH, Timing) | |

| Load capacity | Load current 50mA(Max),AC/DC 30V | |

| Control point | Programmable function(Free chlorine, chlorine dioxide, Temperature, pH, Timing) | |

| Power supply | Connected to electric supply | |

| AC80-260V;50/60Hz,compatible with all international | ||

| market power standards(110V;220V;260V;50/60Hz). | ||

| Working environment | Temperature:(5-50)℃;relative humidity:≤85% RH(non condensation) | |

| Power Consumption | <20W | |

| Storage environment | Temperature:(-20-70)℃;relative humidity:≤85%RH(non condensation) | |

| Installation | Wall mounted(with the preset back cover) | |

| Cabinet weight | ≤10kg | |

| Cabinet dimension | 570*mm*380mm*130mm(H×W×D) | |

Proper storage of ph meter equipment is another important factor in maintaining its accuracy and longevity. pH meters should be stored in a clean, dry place away from direct sunlight and extreme temperatures. Storing pH meters in a protective case or box can help prevent damage and contamination. It is also important to store pH meters with their electrodes immersed in storage solution to prevent them from drying out and becoming damaged.

Regular maintenance of ph meter equipment is essential for ensuring accurate and reliable measurements. In addition to calibration, cleaning, and storage, it is also important to regularly check the condition of the electrodes and replace them when necessary. Signs that the electrodes may need to be replaced include slow response time, drifting readings, or inconsistent results.

When replacing electrodes, it is important to use electrodes that are compatible with the specific model of ph meter being used. Consult the manufacturer’s instructions or contact the manufacturer for guidance on selecting the appropriate replacement electrodes. Proper installation of the new electrodes is also crucial for ensuring accurate measurements.

In conclusion, maintaining and properly storing ph meter equipment is essential for obtaining accurate and reliable measurements. Regular calibration, cleaning, and storage are key components of proper maintenance. Additionally, checking the condition of the electrodes and replacing them when necessary is important for ensuring the continued performance of the ph meter. By following these guidelines, users can ensure that their ph meter equipment remains in optimal condition and provides accurate results for years to come.