Gaskets: Essential for a Perfect Seal.

Introduction to Gaskets: What You Need to Know

Gaskets are an essential component in various industries, playing a crucial role in ensuring the proper functioning of machinery and equipment. These small but mighty devices are used to create a seal between two or more surfaces, preventing the leakage of fluids or gases. In this article, we will delve into the world of gaskets, exploring their different types, materials, and applications.

Gaskets come in a wide range of shapes, sizes, and materials, each designed to meet specific requirements. The most common types of gaskets include sheet gaskets, spiral wound gaskets, ring gaskets, and solid gaskets. Sheet gaskets are made from materials such as rubber, cork, or graphite, and are known for their flexibility and ease of installation. Spiral wound gaskets, on the other hand, consist of a metal winding and a filler material, providing excellent resistance to high temperatures and pressures. Ring gaskets are typically used in flanged connections, while solid gaskets are made from a single piece of material and are often used in low-pressure applications.

The choice of gasket material is crucial, as it determines the gasket’s ability to withstand specific operating conditions. Common materials used for gaskets include rubber, cork, graphite, metal, and PTFE (polytetrafluoroethylene). Rubber gaskets, such as those made from neoprene or silicone, are known for their excellent resistance to water, chemicals, and temperature variations. Cork gaskets are widely used in low-pressure applications due to their compressibility and ability to conform to irregular surfaces. Graphite gaskets are highly resistant to extreme temperatures and corrosive chemicals, making them suitable for demanding environments. Metal gaskets, often made from stainless steel or copper, are known for their durability and ability to withstand high pressures. PTFE gaskets, also known as Teflon gaskets, are widely used in industries where chemical resistance is paramount.

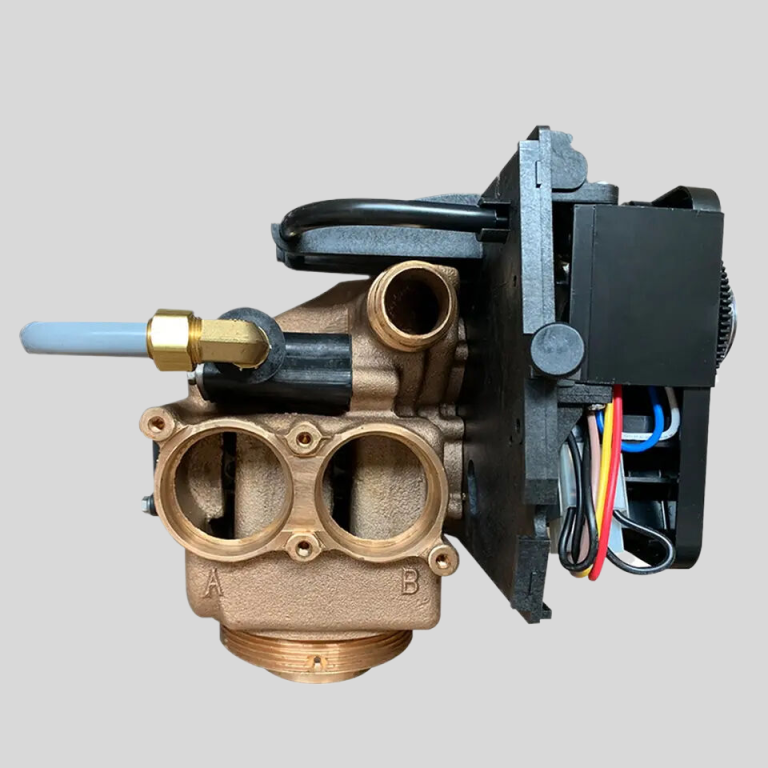

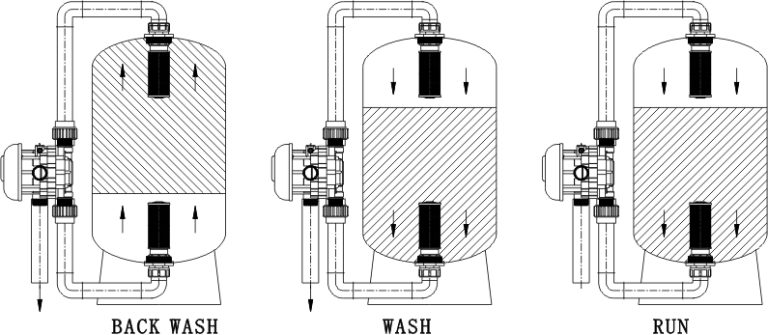

| Model: Manual Filter Valve | MF2 | MF2-H | MF4 | MF4-B | MF10 |

| Working Position | Filter -> Back wash -> Fast rinse ->Filter | ||||

| Regeneration mode | Manual | ||||

| Inlet | 3/4” | 3/4” | 1” | 1” | 2” |

| Outlet | 3/4” | 3/4” | 1” | 1” | 2” |

| Drain | 3/4” | 3/4” | 1” | 1” | 2” |

| Base | 2-1/2” | 2-1/2” | 2-1/2” | 2-1/2” | 4” |

| Riser pipe | 1.05” OD | 1.05” OD | 1.05” OD | 1.05” OD | 1.5”D-GB |

| Water Capacity | 2m3/h | 2m3/h | 4m3/h | 4m3/h | 10m3/h |

| Working Pressure | 0.15-0.6Mpa | ||||

| Working Temperature | 5-50 °C | ||||

| Power Supply | No need Power | ||||

Gaskets find applications in various industries, including automotive, aerospace, oil and gas, pharmaceuticals, and manufacturing. In the automotive industry, gaskets are used in engines, transmissions, and exhaust systems to prevent the leakage of fluids and gases. In the aerospace industry, gaskets are crucial for maintaining airtight seals in aircraft engines and fuel systems. The oil and gas industry relies on gaskets to prevent leaks in pipelines, valves, and storage tanks. In the pharmaceutical industry, gaskets are used in equipment such as pumps and reactors to ensure the integrity of the manufacturing process. In the manufacturing sector, gaskets are used in machinery and equipment to prevent the leakage of fluids and gases, ensuring the safety and efficiency of operations.

In conclusion, gaskets are indispensable components that play a vital role in various industries. Their ability to create a seal between two surfaces prevents the leakage of fluids and gases, ensuring the proper functioning of machinery and equipment. With different types and materials available, gaskets can be tailored to meet specific requirements and operating conditions. Whether it’s in the automotive, aerospace, oil and gas, pharmaceutical, or manufacturing industry, gaskets are essential for maintaining safety, efficiency, and reliability.