Understanding the Purpose of an orp meter

An orp meter, also known as an oxidation-reduction potential meter, is a device used to measure the ability of a solution to oxidize or reduce another substance. This measurement is important in various industries, including water treatment, aquaculture, and food processing. Understanding the purpose of an orp meter is crucial for ensuring the quality and safety of products and processes.

orp meters work by measuring the voltage difference between a reference electrode and a measuring electrode immersed in a solution. This voltage difference is directly related to the concentration of oxidizing or reducing agents in the solution. A positive ORP value indicates that the solution is oxidizing, while a negative value indicates that it is reducing.

In water treatment, orp meters are used to monitor the effectiveness of disinfection processes. For example, in swimming pools, a high ORP value indicates that there is a sufficient amount of chlorine present to kill bacteria and other pathogens. On the other hand, a low ORP value may indicate that the water is not adequately disinfected and could pose a health risk to swimmers.

In aquaculture, orp meters are used to monitor the water quality in fish tanks and ponds. Fish are sensitive to changes in water chemistry, and maintaining the proper ORP level is essential for their health and growth. By regularly measuring the ORP value, aquaculturists can ensure that the water is free from harmful contaminants and that the fish are thriving in a safe environment.

| Model | CLA-7000 Series Free Chlorine(DPD)online automatic analyzer |

| Inlet channel | Single channel/Double channel |

| Measurement range | Free chlorine:(0.0~2.0)mg/L or (0.5~10.0)mg/L ,Calculated as Cl2; pH:(0-14); Temperature(0-100)℃ |

| Accuracy | Free chlorine:±10% or ±0.1/0.25 mg/L; pH:±0.1pH;Temperature:±0.5℃ |

| Measurement Period | ≤2.5min |

| Sampling interval | The interval (1~999) min can be set arbitrarily |

| Maintenance cycle | Recommended once a month (see maintenance chapter) |

| Environmental requirements | A ventilated and dry room without strong vibration;Recommended room temperature:(15~28)℃;Relative humidity:≤85%(No condensation) |

| Water sample flow | (200-400) mL/min |

| Inlet pressure | (0.1-0.3) bar |

| Inlet water temp. | (0-40)℃ |

| Power supply | AC (100-240)V; 50/60Hz |

| Power | 120W |

| Power connection | The 3-core power cord with plug is connected to the mains socket with ground wire |

| Data output | RS232/RS485/(4~20)mA |

| Size | H*W*D:(800*400*200)mm |

In food processing, orp meters are used to monitor the quality and safety of food products. For example, in the production of canned goods, maintaining the proper ORP level is crucial for preventing spoilage and ensuring that the food is safe for consumption. By measuring the ORP value of the food during processing, manufacturers can identify any potential issues and take corrective action to prevent contamination.

Overall, the purpose of an orp meter is to provide a quick and accurate measurement of the oxidation-reduction potential of a solution. By monitoring this value, industries can ensure the quality and safety of their products and processes. orp meters are versatile tools that can be used in a wide range of applications, from water treatment to food processing, and are essential for maintaining high standards of quality and safety.

In conclusion, understanding the purpose of an orp meter is essential for anyone working in industries where water quality and product safety are paramount. By using an orp meter to monitor the oxidation-reduction potential of solutions, industries can ensure that their processes are efficient, effective, and safe. orp meters are valuable tools that provide valuable insights into the chemical composition of solutions and play a crucial role in maintaining high standards of quality and safety.

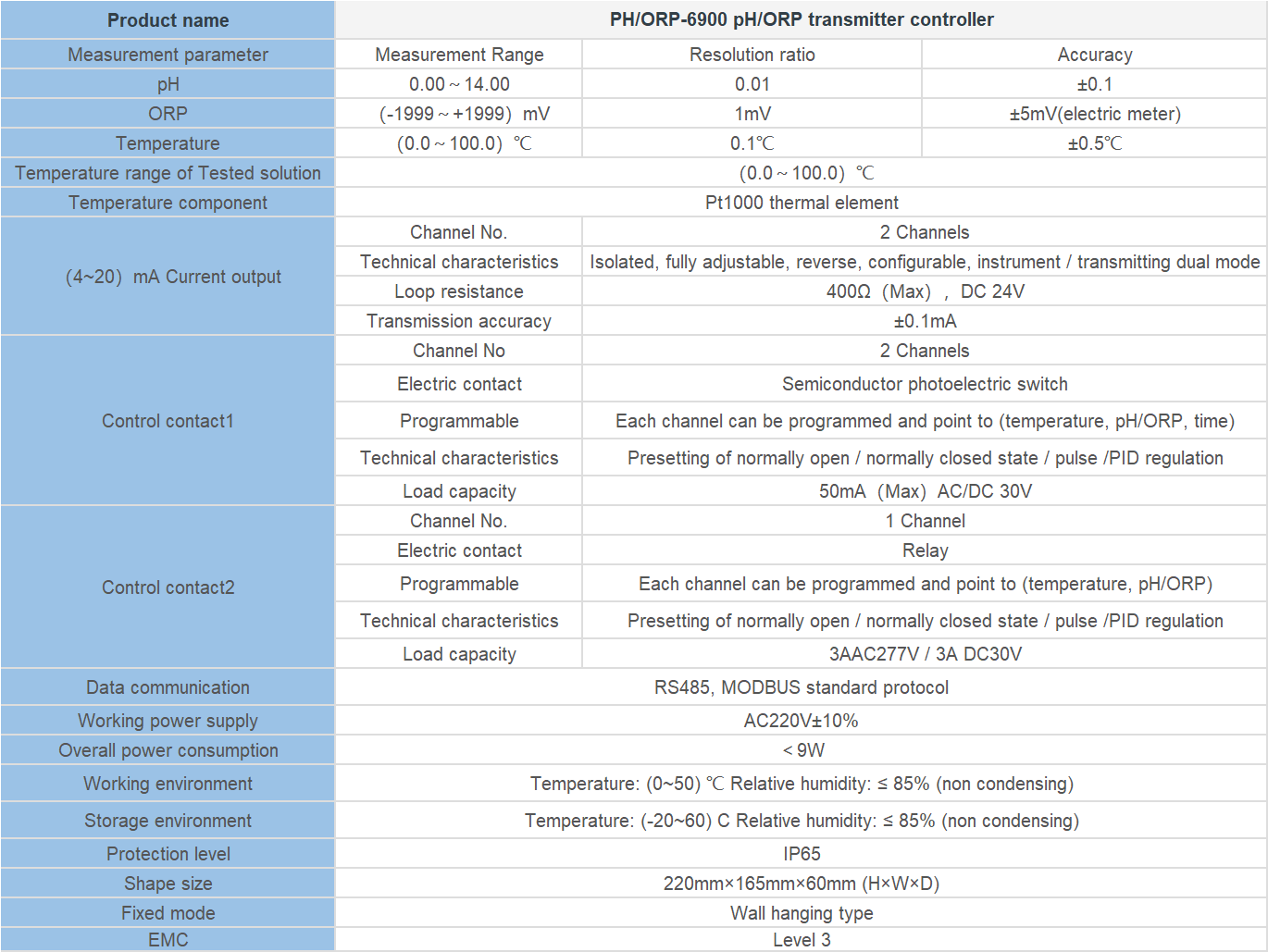

| Model | pH/ORP-510 pH/orp meter |

| Range | 0-14 pH; -2000 – +2000mV |

| Accuracy | ±0.1pH; ±2mV |

| Temp. Comp. | Manual/Automatic temperature compensation; No Comp. |

| Oper. Temp. | Normal 0~60℃; High temp 0~100℃ |

| Sensor | pH double/triple sensor; ORP sensor |

| Display | LCD Screen |

| Communication | 4-20mA output/RS485 |

| Output | High/Low limit dual relay control |

| Power | AC 220V±10% 50/60Hz or AC 110V±10% 50/60Hz or DC24V/0.5A |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 48×96×100mm(H×W×L) |

| Hole Size | 45×92mm(H×W) |

| Installation Mode | Embedded |