No products were found matching your selection.

Other Related Products

-

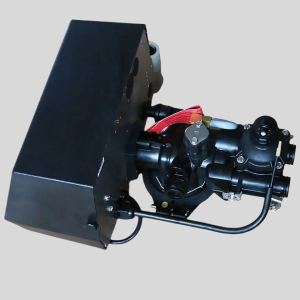

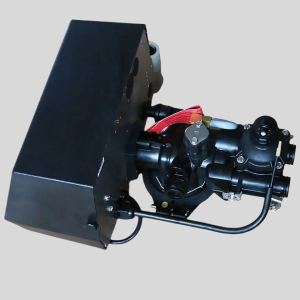

ZR type double tank floating bed control valve including ZR4-1/ZR4-1S(Side Loading), ZR10-1/ZR10-1S(Side Loading). It is equiped the inlet flow Meter and drainage flow meter, All the parameters is set by water volume, The double swap tank is for Alternating regeneration. Continuous water production, Water quality is stable , Adapted to the to high hardness water softening, such as the steam boiler and heating engineering and production process water.

-

High Cost-Effective ,widely used for chemical industry,paper making industry,industrial coating,pharmaceutical,food,beverage,municipal water,Environmental and so on.

-

Widely used in water purifiers, business water machines, pure water machine

Easy to use with reduced installation time

Can be used on a variety of pipes including copper pipe

No tools required

Fittings are cost-effective reusable components for maximum flexibility

For warm and cold water

Corrosion-free with no scale build-up

-

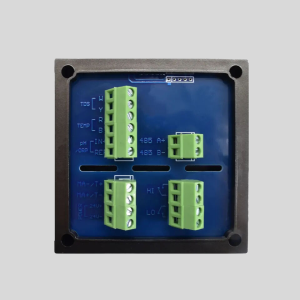

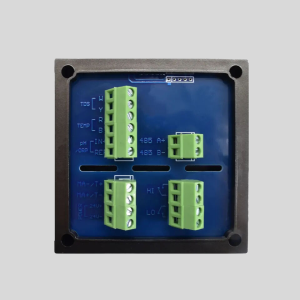

GL-2 Series of economical control valve is the same as the corresponding GL-1 in function and principle. it use “One dynamic & two static” three layer ceramic valve core technology, It adopts four key controller operation setting method, needless rotation station identification when power on every time.The inlet and outlet water is set on the side of the valve body.Small size, simple structure, no wear and tear, permanent life.It can be widely used in the purification of industrial and civil.

-

Typical applications • Widely used in thermal boiler deaerator water and large and medium-sized industrial boiler feed water; • Operational supervision of reactor Primary circuit, secondary circuit circuits and condensate system; • On-line analysis of dissolved oxygen in circulating water of heat exchange system; • Deaeration control of marine fresh water system, thermal system and…

-

On-line analysis and process control of the oil refining, metallurgy,chemical synthesis industry process;

-

Fully adjustable, 5-cycle control delivers upflow backwash, downflow brining, slow rinse, rapid rinse, brine refill, and downflow service

Time-tested, hydraulically-balanced piston, seal and spacer, controls service flow and regeneration

Non-corrosive, fiber-reinforced polymer construction

Excellent flow rates (19 GPM continuous, 24 GPM peak)

Backwash capacity handles tanks up to 16″ diameter for softener, and filter

-

1) Automatic softener valve Downflow and upflow type.

2) Downflow & Upflow Working Position :

a) Service->Back Wash->Downflow Brine and slow rinse->Refill ->Fast rinse->Service.

b) Service->Back Wash->Upflow Brine and slow rinse->Refill ->Fast rinse->Service.

3) Using ceramic moving valve disk, small rotation torque.

4) Abrasion resistance of the sealing surface, outstanding and long-lived deal.

5) It could be operated with pressure directly.

-

FLECK control valve 5600 softening water equipment generally uses fixed bed downstream

regeneration, the working process is operation, backwashing, regeneration, replacement,

positive washing, salt tank water injection.