Table of Contents

Common Causes of E9 Flow Sensor Faults

E9 flow sensor faults are a common issue that can occur in various types of equipment and machinery. These faults can be frustrating to deal with, as they can cause disruptions in operations and lead to costly repairs. Understanding the common causes of E9 flow sensor faults can help you prevent them from happening in the first place.

One of the most common causes of E9 flow sensor faults is a buildup of debris or contaminants in the sensor. Over time, dirt, dust, and other particles can accumulate in the sensor, causing it to malfunction. This can lead to inaccurate readings and ultimately result in a fault being triggered. Regular cleaning and maintenance of the sensor can help prevent this issue from occurring.

Another common cause of E9 flow sensor faults is damage to the sensor itself. This can happen due to physical impact, exposure to harsh chemicals or extreme temperatures, or simply wear and tear over time. If the sensor is damaged, it may not be able to accurately measure flow rates, leading to a fault being triggered. Regular inspections and replacement of damaged sensors can help prevent this issue.

Calibration issues can also lead to E9 flow sensor faults. If the sensor is not calibrated correctly, it may not be able to accurately measure flow rates. This can result in inaccurate readings and trigger a fault. Regular calibration of the sensor can help ensure that it is functioning properly and prevent faults from occurring.

In some cases, software or firmware issues can cause E9 flow sensor faults. If there is a bug or glitch in the software that controls the sensor, it may not be able to function properly. This can lead to faulty readings and trigger a fault. Updating the software or firmware regularly can help prevent this issue from occurring.

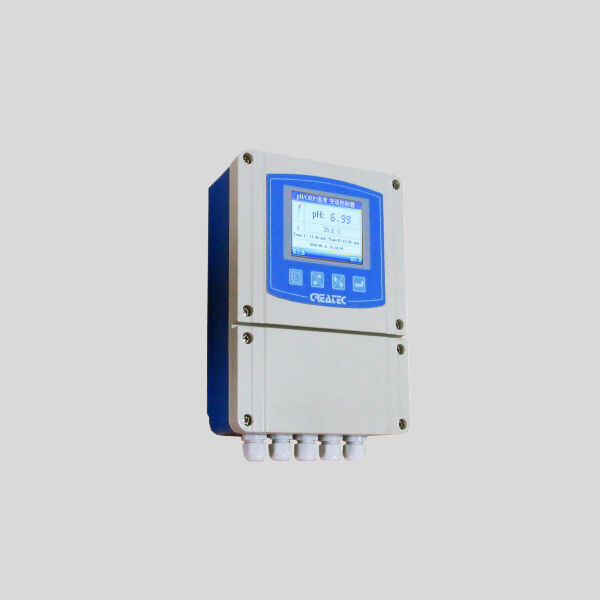

| POP-8300 free chlorine online analyzer | ||

| System Model | POP-8300 free chlorine online analyzer | |

| Measurement configuration | (HClO)free chlorine.. | |

| total free chlorine/(ClO2)/pH/Temperature | ||

| Free chlorine | (0.00-2.00)mg/L(ppm); (0.00-20.00)mg/L(ppm) | |

| Measurement | pH | 2.00-12.00 |

| range | Temperature | (0.0-99.9)℃ |

| Free chlorine | 0.01mg/L(ppm) | |

| Resolution | pH | 0.01 |

| Temperature | 0.1℃ | |

| Free chlorine | Indication error 10% | |

| Accuracy | pH | 0.1pH |

| Temperature | ±0.5℃ | |

| Sensor life | pH/free chlorine sensor | 12months(The service life is closely related to the measurement medium and maintenance frequency) |

| Communication interface | RS485 | MODBUS RTU communication protocol |

| Number of channels | Double channels | |

| (4-20)mA | Technical feature | Isolated, reversible, completely adjustable, instrument/transmitter dual mode |

| output | Channel configuration | Programmable point to Free chlorine, chlorine dioxide, Temperature, pH |

| Loop resistance | 400Ω(Max), DC 24V | |

| Transmission accuracy | ±0.1mA | |

| Number of channels | Double channels | |

| Contact mode | The first and second for photoelectric switch | |

| Control output | Load capacity | Load current 50mA(Max),AC/DC 30V |

| Control point | Programmable function(Free chlorine, chlorine dioxide, Temperature, pH, Timing) | |

| Load capacity | Load current 50mA(Max),AC/DC 30V | |

| Control point | Programmable function(Free chlorine, chlorine dioxide, Temperature, pH, Timing) | |

| Power supply | Connected to electric supply | |

| AC80-260V;50/60Hz,compatible with all international | ||

| market power standards(110V;220V;260V;50/60Hz). | ||

| Working environment | Temperature:(5-50)℃;relative humidity:≤85% RH(non condensation) | |

| Power Consumption | <20W | |

| Storage environment | Temperature:(-20-70)℃;relative humidity:≤85%RH(non condensation) | |

| Installation | Wall mounted(with the preset back cover) | |

| Cabinet weight | ≤10kg | |

| Cabinet dimension | 570*mm*380mm*130mm(H×W×D) | |

In conclusion, E9 flow sensor faults can be caused by a variety of factors, including debris buildup, sensor damage, electrical issues, calibration issues, and software or firmware issues. Regular maintenance, inspection, and calibration of the sensor can help prevent these faults from occurring. By understanding the common causes of E9 flow sensor faults and taking proactive measures to address them, you can ensure that your equipment operates smoothly and efficiently.

Troubleshooting and Fixing E9 Flow Sensor Faults

E9 Flow Sensor Faults can be a common issue that arises in various systems that rely on flow sensors for accurate measurements. These faults can lead to inaccurate readings, system malfunctions, and potential damage if not addressed promptly. In this article, we will discuss the common causes of E9 Flow Sensor Faults, how to troubleshoot them, and steps to fix the issue.

| Model | FL-9900 Paddle Wheel flow meter |

| Range | Flow Speed:0.5-5 m/s |

| Instantaneous Flow:0-2000m3/h | |

| Accuracy | Level 2 |

| Temp. Comp. | Automatic temperature compensation |

| Oper. Temp. | Normal 0~60℃; High temp 0~100℃ |

| Sensor | Paddle Wheel Sensor |

| Pipeline | DN20-DN300 |

| Communication | 4-20mA output/RS485 |

| Control | Instantaneous Flow High/Low alarm |

| Load Current 5A(Max) | |

| Power | 220V/110V/24V |

| Working Environment | Ambient temperature:0~50℃ |

| Relative humidity≤85% | |

| Dimensions | 96×96×72mm(H×W×L) |

| Hole Size | 92×92mm(H×W) |

| Installation Mode | Embedded |

One of the primary causes of E9 Flow Sensor Faults is a dirty or clogged sensor. Over time, debris, sediment, or other contaminants can build up on the sensor, affecting its ability to accurately measure flow. To troubleshoot this issue, start by inspecting the sensor for any visible signs of dirt or debris. If you notice any buildup, carefully clean the sensor using a soft brush or cloth to remove the contaminants. Be sure to follow the manufacturer’s guidelines for cleaning to avoid damaging the sensor.

Another common cause of E9 Flow Sensor Faults is a faulty sensor connection. Poor wiring or loose connections can disrupt the flow of data between the sensor and the system, leading to inaccurate readings or sensor malfunctions. To troubleshoot this issue, check the sensor’s wiring and connections for any signs of damage or looseness. If you find any issues, carefully rewire or tighten the connections to ensure a secure and reliable connection.

In some cases, E9 Flow Sensor Faults may be caused by a malfunctioning sensor itself. Sensors can wear out over time or become damaged due to environmental factors, leading to inaccurate readings or system malfunctions. To troubleshoot this issue, consider replacing the sensor with a new one to see if the problem persists. Be sure to choose a sensor that is compatible with your system and meets the necessary specifications for accurate flow measurement.

If you have tried troubleshooting the E9 Flow Sensor Faults and are still experiencing issues, it may be necessary to seek professional help. A qualified technician can diagnose the problem more accurately and recommend the best course of action to fix the issue. They may perform additional tests, inspections, or repairs to ensure that the flow sensor is functioning correctly and providing accurate readings.

In conclusion, E9 Flow Sensor Faults can be a frustrating issue to deal with, but with proper troubleshooting and maintenance, you can address the problem effectively. By cleaning the sensor, checking connections, and replacing faulty sensors when necessary, you can ensure that your system operates smoothly and accurately. If you are unable to resolve the issue on your own, don’t hesitate to seek professional help to diagnose and fix the problem. Remember, accurate flow measurements are essential for the proper functioning of various systems, so it’s important to address E9 Flow Sensor Faults promptly to avoid any potential damage or malfunctions.